Welding seam recognition method based on piecewise linear fitting

A recognition method, piecewise linear technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of lack of versatility, long matching process, poor adaptability, etc., to improve applicability and simplify calculation. Level complexity, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical solutions and features of the present invention more clearly understood, the present invention will be further described below in conjunction with the accompanying drawings.

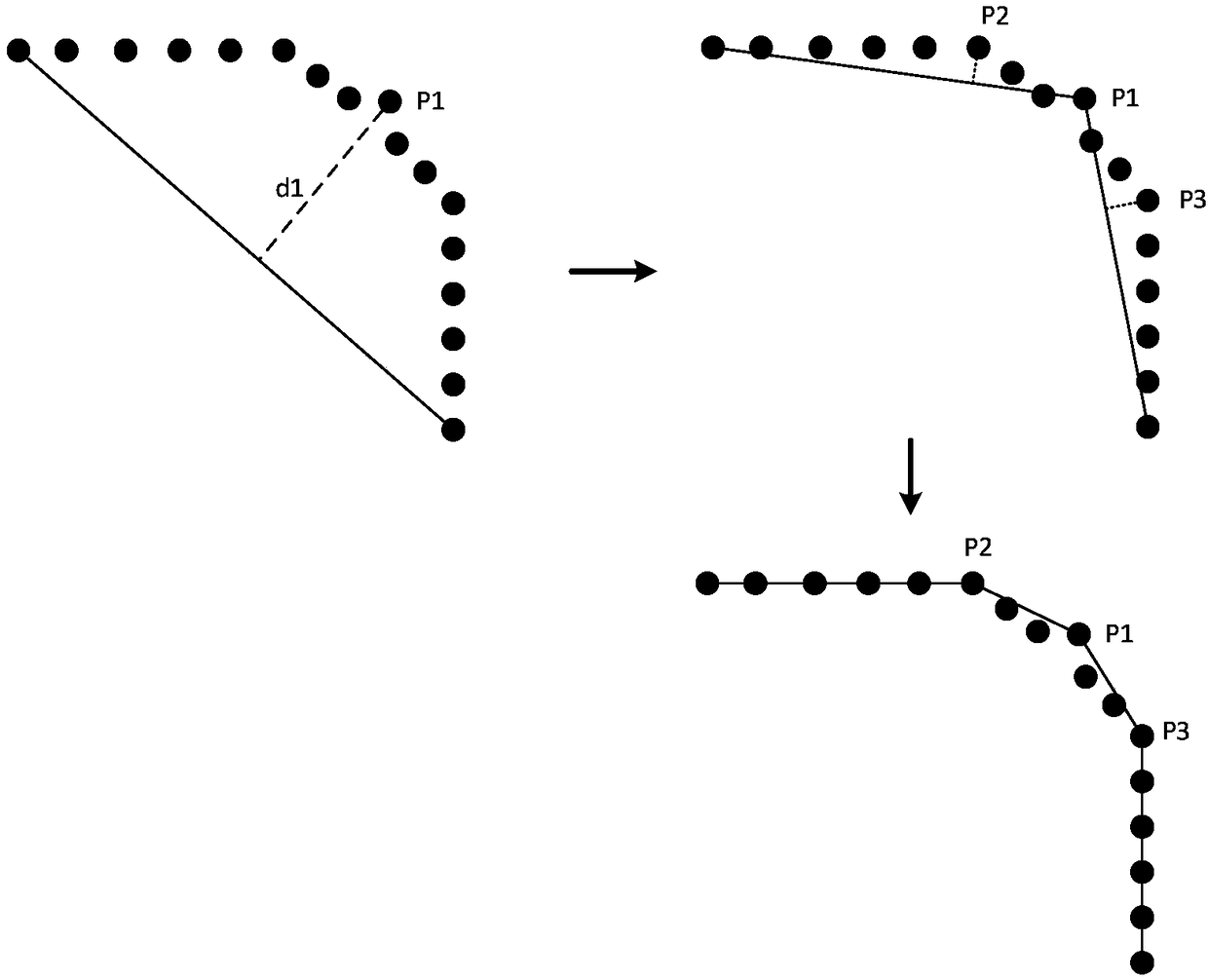

[0042] As shown in 1 to 4, a weld recognition method based on piecewise linear fitting, including steps:

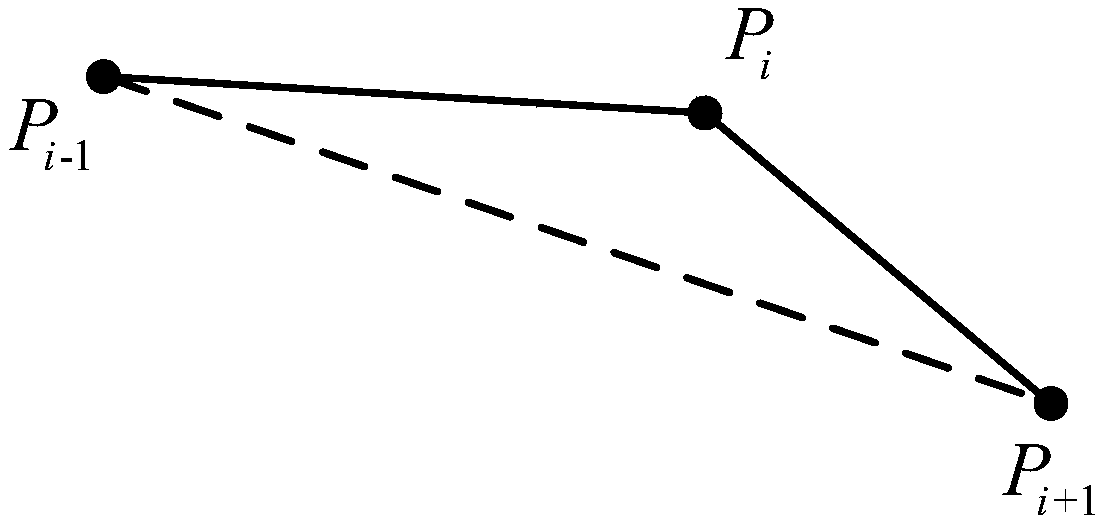

[0043] S1. Obtain a series of discrete points of the laser centerline, and segment the discrete points by means of recursive subdivision;

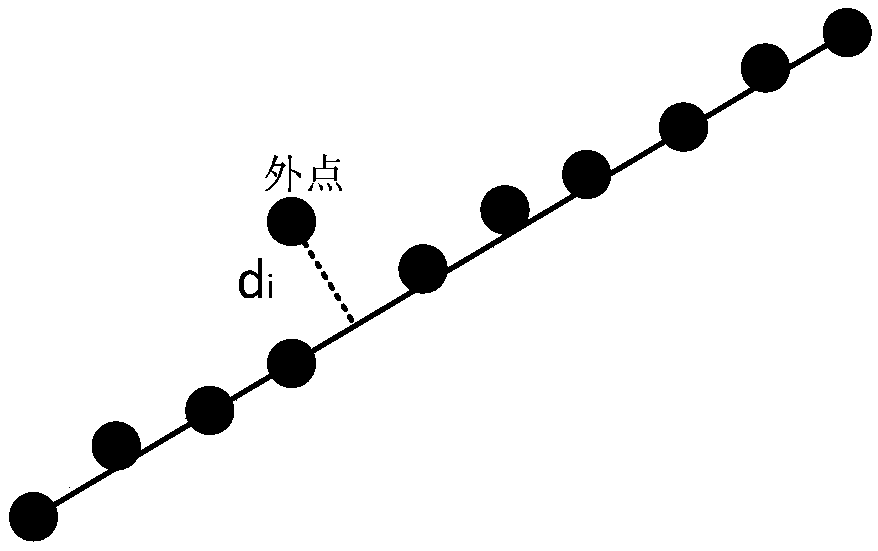

[0044] S2. In the discrete points of each segment, the internal point of the discrete points of the segment is searched in a random sampling consistent manner;

[0045] S3. Judging the ratio w between the number of interior points sought and the number of discrete points in this section, when the ratio w is greater than the threshold we, output the interior points sought and fit the interior points into a straight line, otherwise return to step S2 until the laser center All discrete points of the line become ordered straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com