Automatic detection method for loose fault of end bolt of crossover support device of train bogie

A cross-bracing and bolt loosening technology, applied in railway vehicle testing, image data processing, instruments, etc., can solve problems such as poor real-time performance, waste of human resources, and bolts falling off, and achieve high real-time performance, high integrity, and strong robustness. performance and noise immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

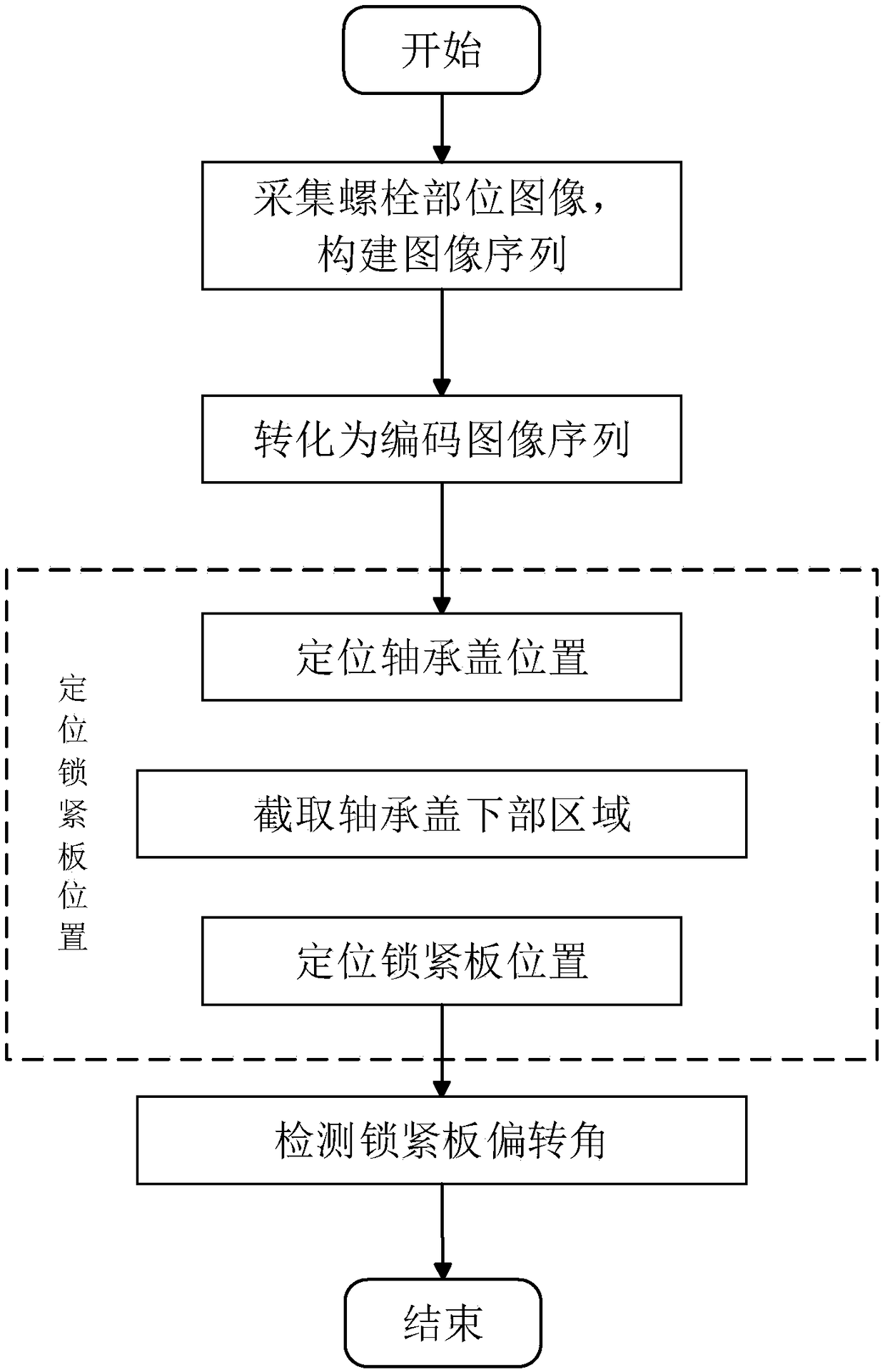

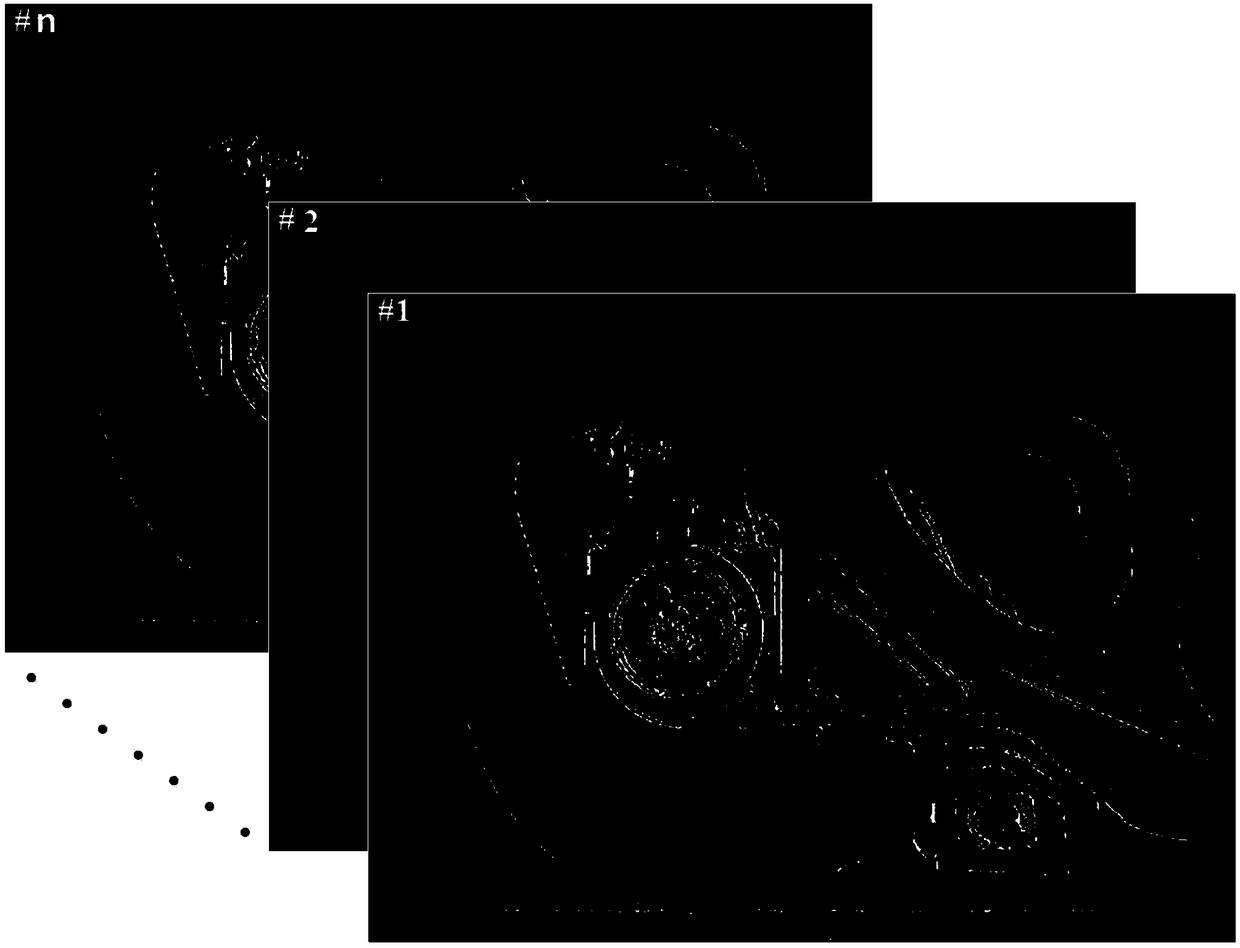

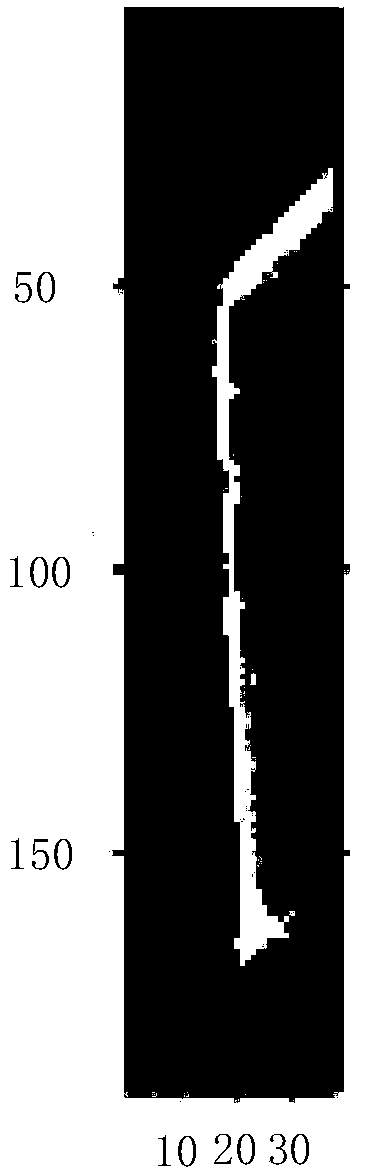

[0061] This embodiment takes the automatic detection of bolt loosening failure at the end of the cross support device of the railway freight car bogie as an example. The steps of bolt position image and image sequence construction; the step of converting the grayscale image sequence into a coded image sequence; the steps of locating the position of the locking plate and the steps of detecting the deflection angle of the locking plate; finally realizing the end of the cross support device of the railway freight car bogie The identification of bolt loosening faults, the specific implementation is as follows: figure 1 shown, including the following steps:

[0062] Step S1, collecting images of bolts at the end of the train bogie cross support device and constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com