Heating roller heating based cleaning device for thermal-sublimation developing machine

A technology of cleaning device and heating roller, applied in the direction of cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problems of low efficiency, poor product, affecting the cleanliness of cloth, etc., and achieve cleaning effect Excellent, simple structure, convenient and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

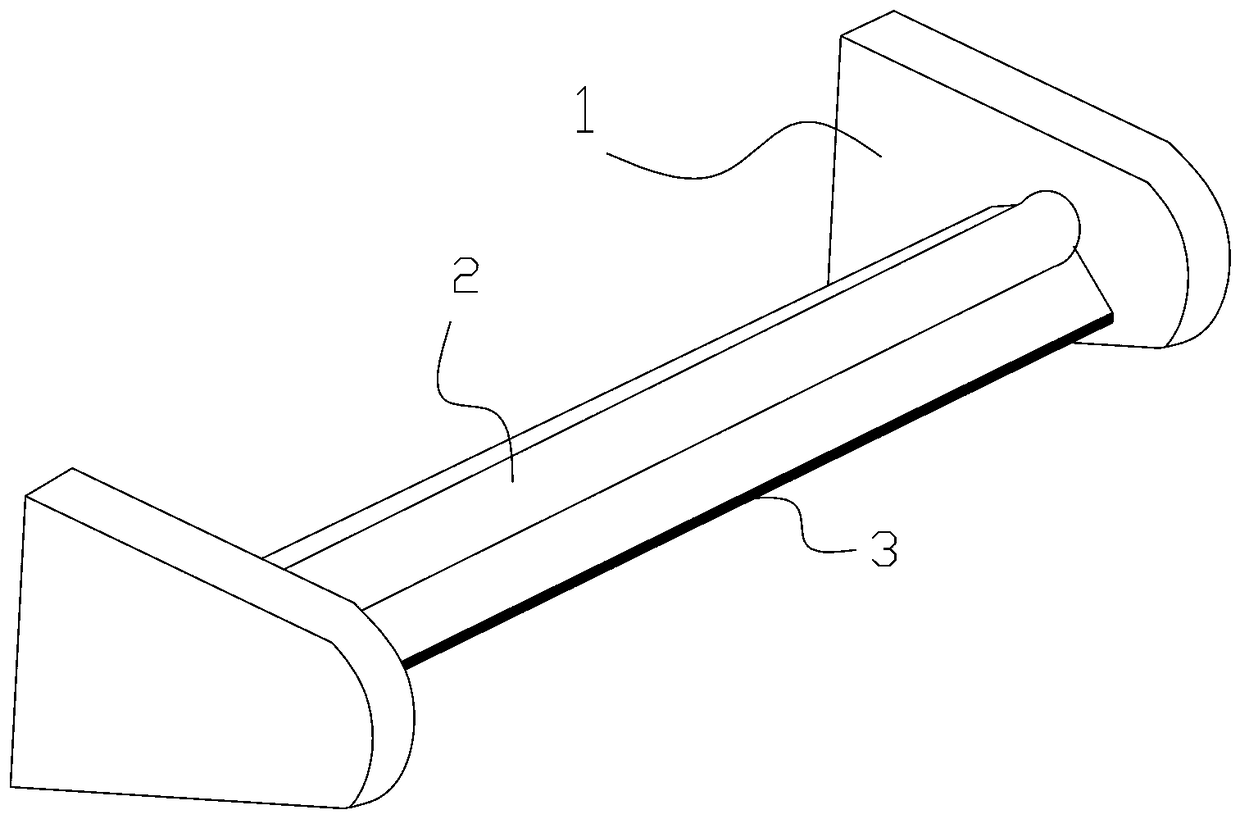

[0030] Such as figure 1 As shown, this embodiment provides a cleaning device for a thermal sublimation color development machine based on the heating of a heating roller, including:

[0031] fixed bracket 1;

[0032] A counterweight 2, the two ends of the counterweight 2 are respectively rotatably connected to one of the fixed brackets 1;

[0033] The cleaning medium 3 is arranged on the surface of the counterweight 2 on the downward side subjected to gravity.

[0034] When designing, the fixed bracket 1 can be conveniently installed on the feeding side of the dye sublimation color development machine. The two ends of the counterweight 2 are cylindrical and connected to the fixed bracket 1 in rotation. The surface on the downward side is a smooth plane, and the preferred softness of the cleaning medium 3 has a certain friction surface, but it is a material that damages the heating roller surface little.

[0035] When not in use, the cleaning device is equipped with a side o...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that in this embodiment, the outer surface of the counterweight 2 is wrapped with a cloth layer, and the cleaning medium 3 is detachably bonded to the cloth layer by Velcro. It is conducive to the timely replacement of the cleaning medium 3, and avoids the decline of the cleaning effect of the cleaning medium 3 due to more residual dyes. It should be noted that the purpose of setting the cloth layer is only to facilitate the fixing of the Velcro on it, so that the cleaning medium 3 can better cooperate with the counterweight 2, so the type of cloth is not limited. Specifically, the Velcro is preferred. The suede surface is set on the cleaning medium 3, and the hook surface is set on the fabric layer. Long-term experiments have proved that the hook surface has a longer service life, so the fabric layer that does not need to be replaced frequently is preferably stitched with the hook surface.

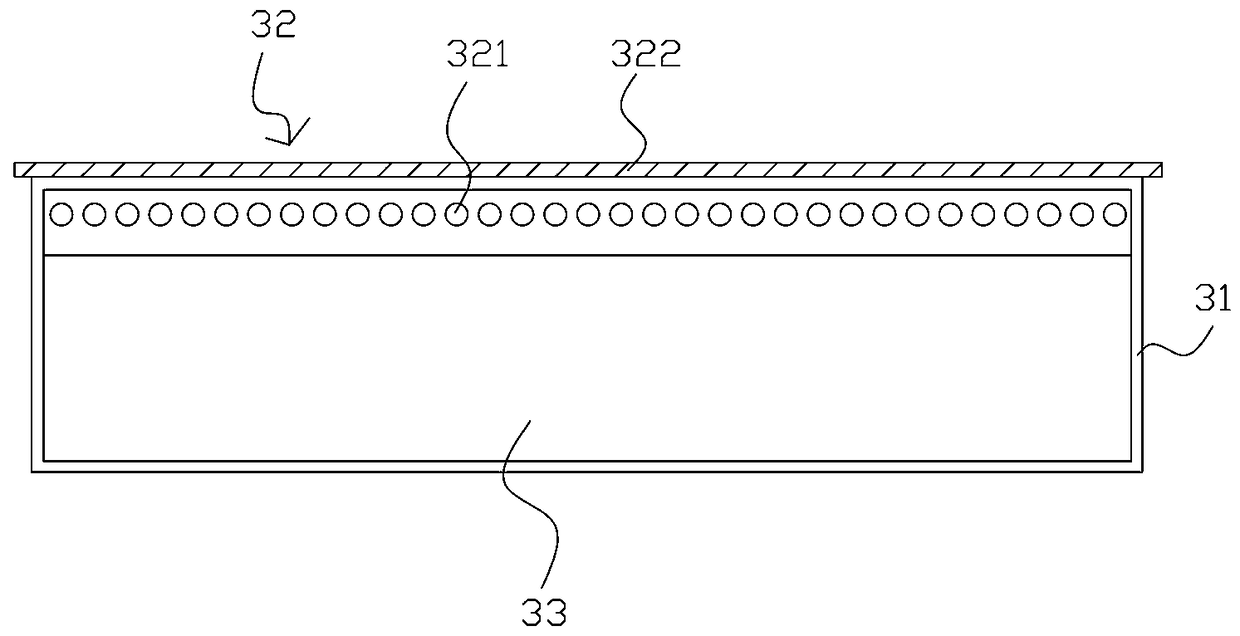

[0039] The surface ...

Embodiment 3

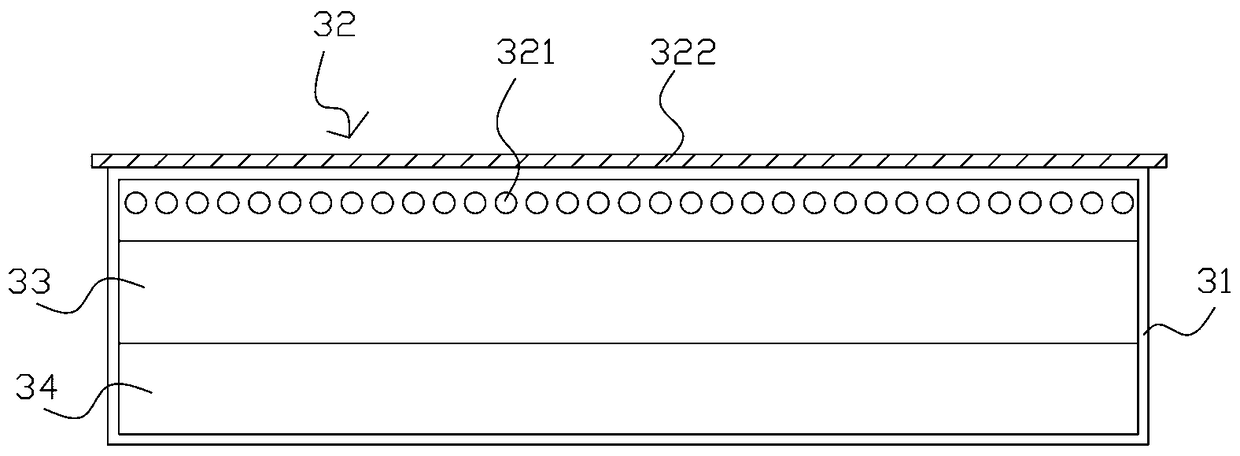

[0044] Such as image 3As shown, the difference between this embodiment and Embodiment 2 is that the cleaning medium 3 in this embodiment also includes a water absorption area 34, and the water absorption area 34 is provided at a side of the friction cleaning area 33 away from the nozzle area 32. side and is detachably connected to the mounting plate 31. It is beneficial to absorb the liquid residue on the surface of the heating roller. When the water absorption capacity of the water absorption area 34 is low, the water absorption area 34 can be replaced to continue to absorb water.

[0045] The water-absorbing area 34 is composed of water-absorbing cotton or a water-absorbing bag wrapped with powder desiccant. In addition to absorbing water, the absorbent cotton can also wipe the surface of the heating roller, and further remove the residual dye that has not been cleaned in the friction cleaning area 33. The outer packaging material of the absorbent bag wrapped with powder d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com