Manufacturing process of gold watch parts

A manufacturing process and parts technology, applied in the field of gold watch parts manufacturing technology, can solve the problems of insufficient processing precision of watch parts, fuzzy patterns of parts, complex processing procedures, etc., to achieve increased flatness, narrow slits, The effect of shortening the process flow and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

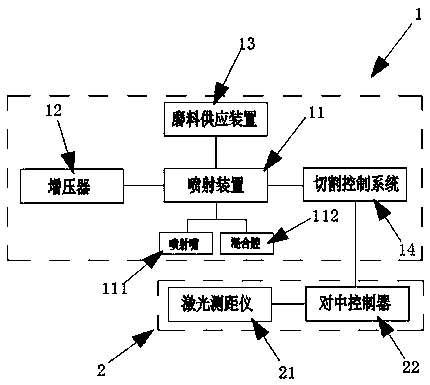

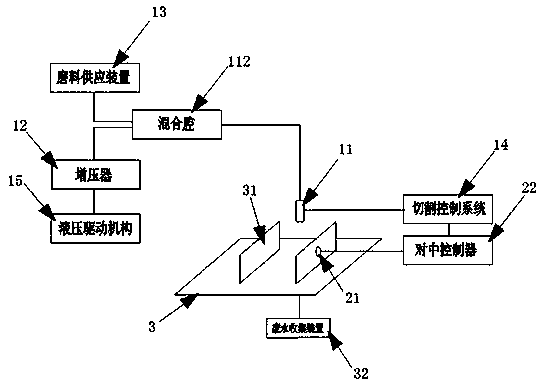

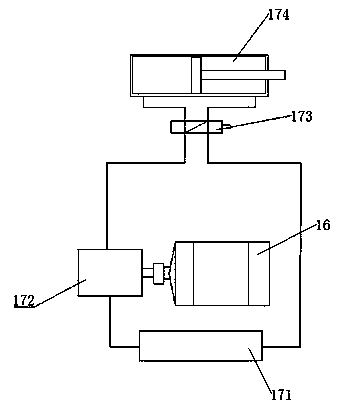

Method used

Image

Examples

Embodiment 1

[0033] A manufacturing process of gold watch parts, specifically comprising the following steps:

[0034] S1. Blank making: the metal or metal alloy that can chemically react with hydrochloric acid, nitric acid or sulfuric acid is used to press the inner blank of watch parts with the same pattern on the upper and lower sides and symmetrical thickness, and then finish it;

[0035] S2. Electroforming: Electroforming deposition is performed on the surface of the inner billet of the watch parts after pressing to form a gold layer;

[0036] S3. Cutting: Use the cold cutting process to symmetrically cut the watch parts, and form two sets of watch parts at one time; the cold cutting process uses a high-pressure water jet cold cutting process, the jet water pressure is 800MPa, and 100 mesh is added to the water flow Silica as abrasive;

[0037] S4, remove the inner blank of the watch parts; the watch parts with the inner blank formed after the S3 cold cutting process are first placed...

Embodiment 2

[0044] A manufacturing process of gold watch parts, specifically comprising the following steps:

[0045] S1. Blank making: the metal or metal alloy that can chemically react with hydrochloric acid, nitric acid or sulfuric acid is used to press the inner blank of watch parts with the same pattern on the upper and lower sides and symmetrical thickness, and then finish it;

[0046] S2. Electroforming: Electroforming deposition is performed on the surface of the inner billet of the watch parts after pressing to form a gold layer;

[0047] S3. Cutting: Use the cold cutting process to symmetrically cut the watch parts, and form two sets of watch parts at one time; the cold cutting process uses a high-pressure water jet cold cutting process, the jet water pressure is 1200MPa, and 200 mesh is added to the water flow Silica as abrasive;

[0048] S4, remove the inner blank of the watch parts; the watch parts with the inner blank formed after the S3 cold cutting process are first place...

Embodiment 3

[0055] A manufacturing process of gold watch parts, specifically comprising the following steps:

[0056] S1. Blank making: the metal or metal alloy that can chemically react with hydrochloric acid, nitric acid or sulfuric acid is used to press the inner blank of watch parts with the same pattern on the upper and lower sides and symmetrical thickness, and then finish it;

[0057] S2. Electroforming: Electroforming deposition is performed on the surface of the inner billet of the watch parts after pressing to form a gold layer;

[0058] S3. Cutting: Use the cold cutting process to symmetrically cut the watch parts, and form two sets of watch parts at one time; the cold cutting process uses a high-pressure water jet cold cutting process, the jet water pressure is 1000MPa, and 200 mesh is added to the water flow Garnet as an abrasive;

[0059] S4, remove the inner blank of the watch parts; the watch parts with the inner blank formed after the S3 cold cutting process are first pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com