An environmentally friendly glass fiber production line

A glass fiber and production line technology, applied in glass recycling, grain processing, recycling technology, etc., can solve problems such as insufficient crushing and grinding of stone materials, achieve the effects of improving efficiency, improving work efficiency, and ensuring work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

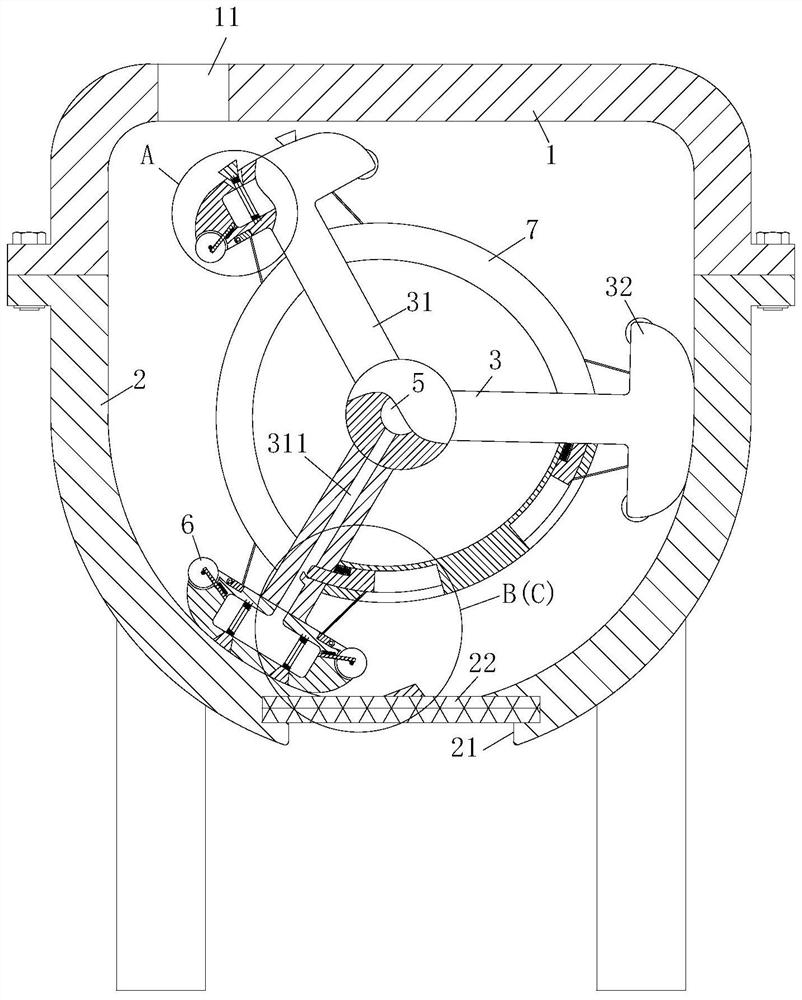

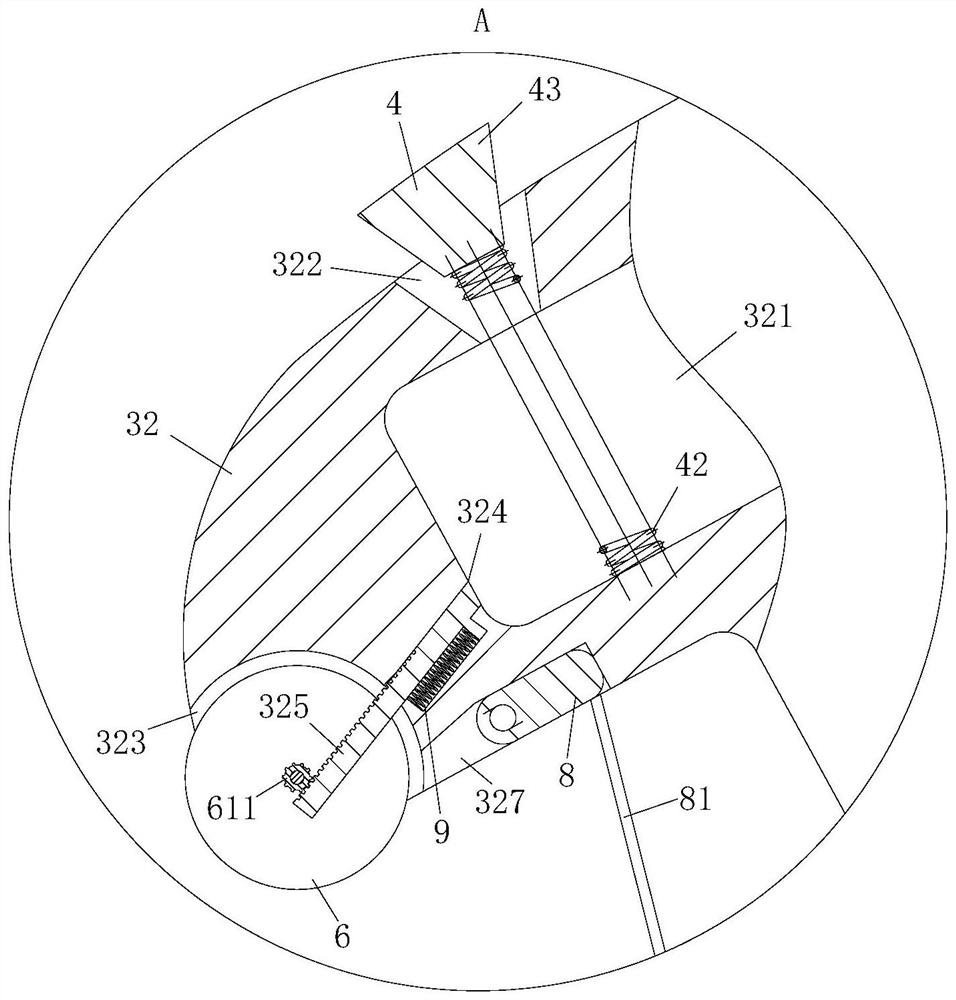

[0037] As a specific embodiment of the present invention, the screen 22 is higher than the discharge port 21, and the screen 22 is provided with a convex block 221 with a triangular cross-section; 221 will make the screen 22 move up and down to vibrate, thereby preventing the screen 22 from being blocked; during use, when the grinding block 32 rotates to the bottom of the cylinder 2, because the screen 22 is higher than the discharge port 21, and the screen 22 is set There are bumps 221. At this time, the grinding block 32 will squeeze the bumps 221, so that the screen 22 will vibrate up and down. Under the vibration of the screen 22, the stones that meet the particle size are more likely to enter the discharge device through the screen 22. In addition, the vibration of the screen mesh 22 also avoids clogging of the screen mesh 22 due to the accumulation of stones, and improves the use efficiency of the crushing equipment.

[0038] When using, first of all, since the feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com