Cycloid pin type non-equidistant polar coordinate irregular workpiece water jet cutting device

A technology for special-shaped workpieces and cutting devices, which is applied to used abrasive processing devices, manufacturing tools, metal processing equipment, etc., and can solve the problem that the synchronous rotation of the arm and the circumferential rotation arm cannot be synchronized and the rotation angle of the entire rotation cannot be accurately controlled. The stability of the position of the rotating arm, the inability to expand the application range of cutting workpieces with spatial shapes, and the inability to adjust the position of the nozzle chuck on the circumferential rotating arm have achieved the effect of expanding the application range of cutting, simple structure, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

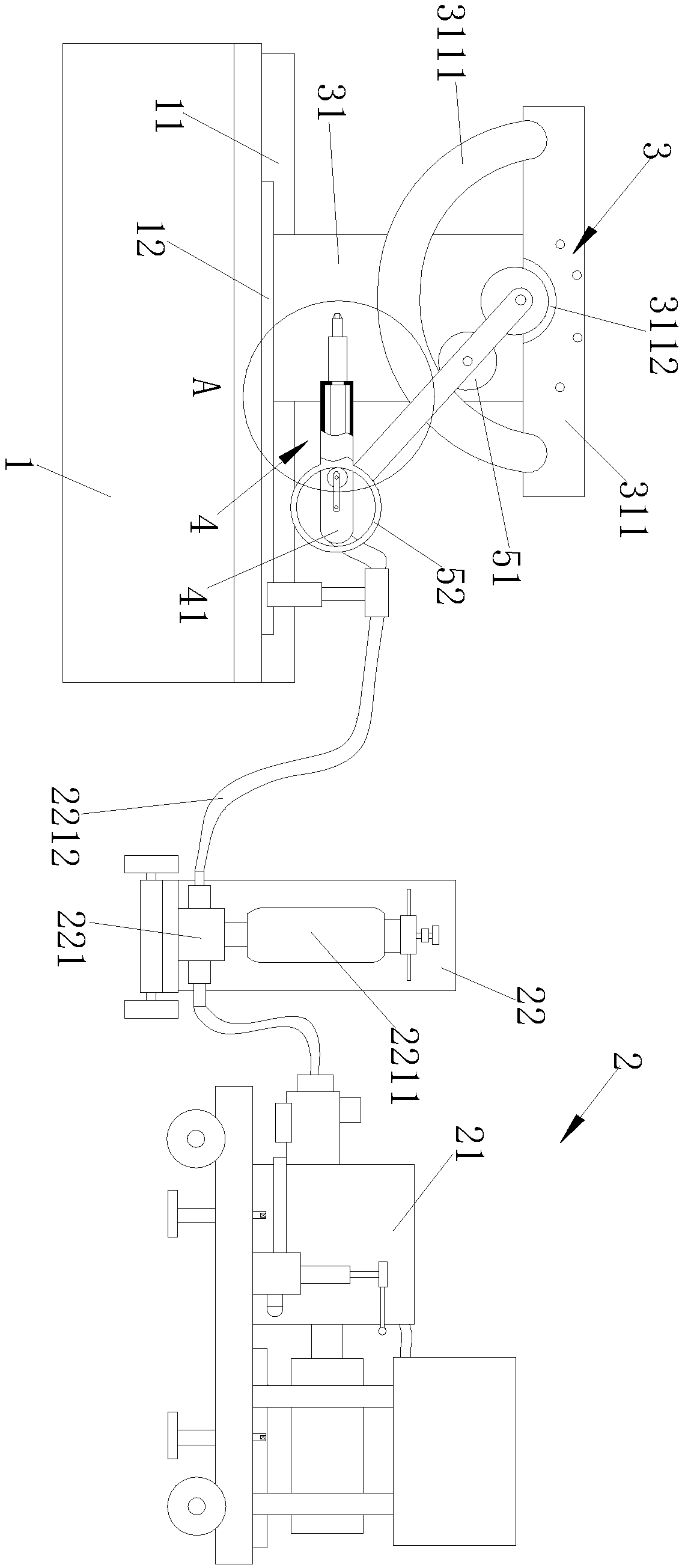

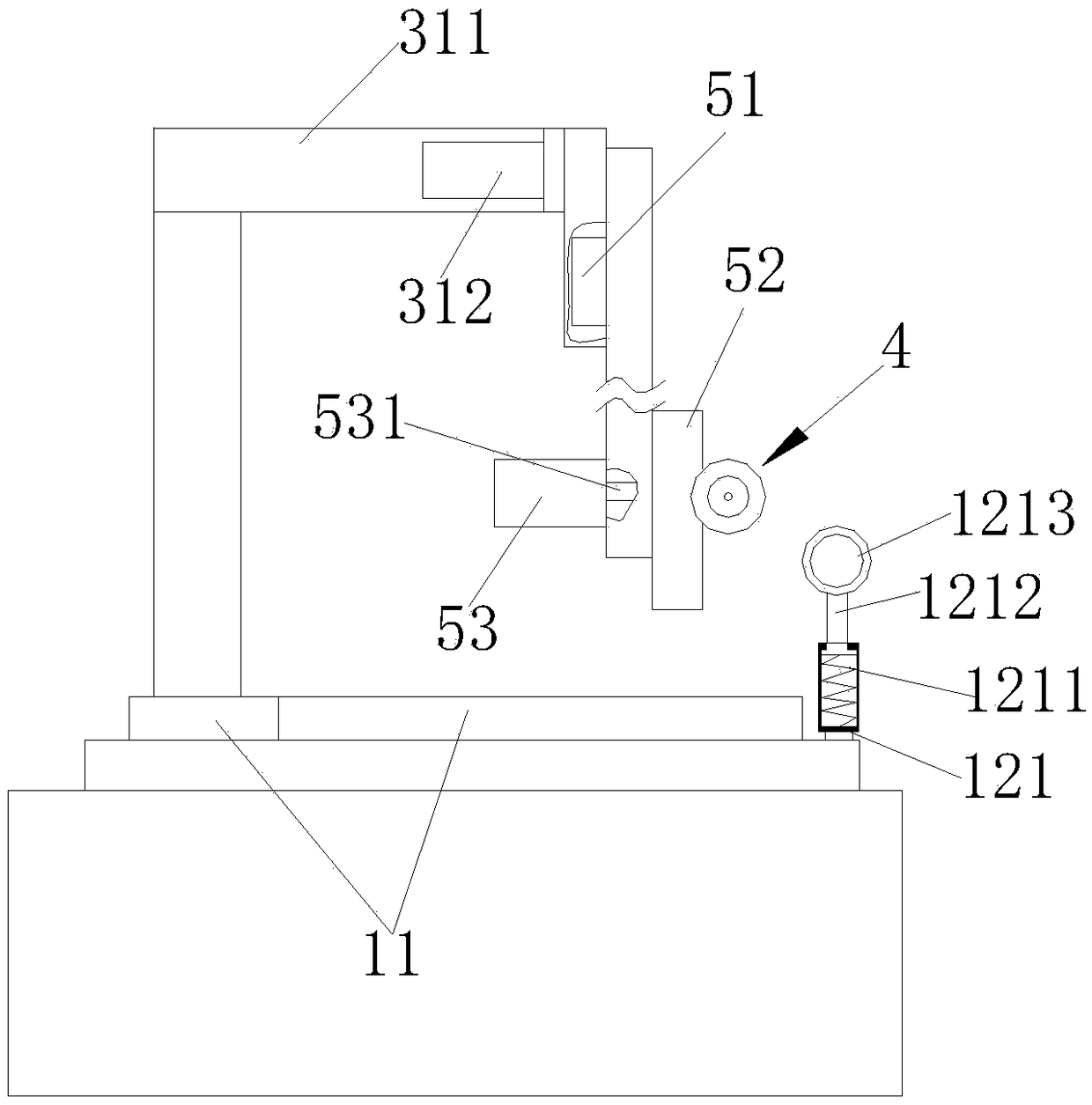

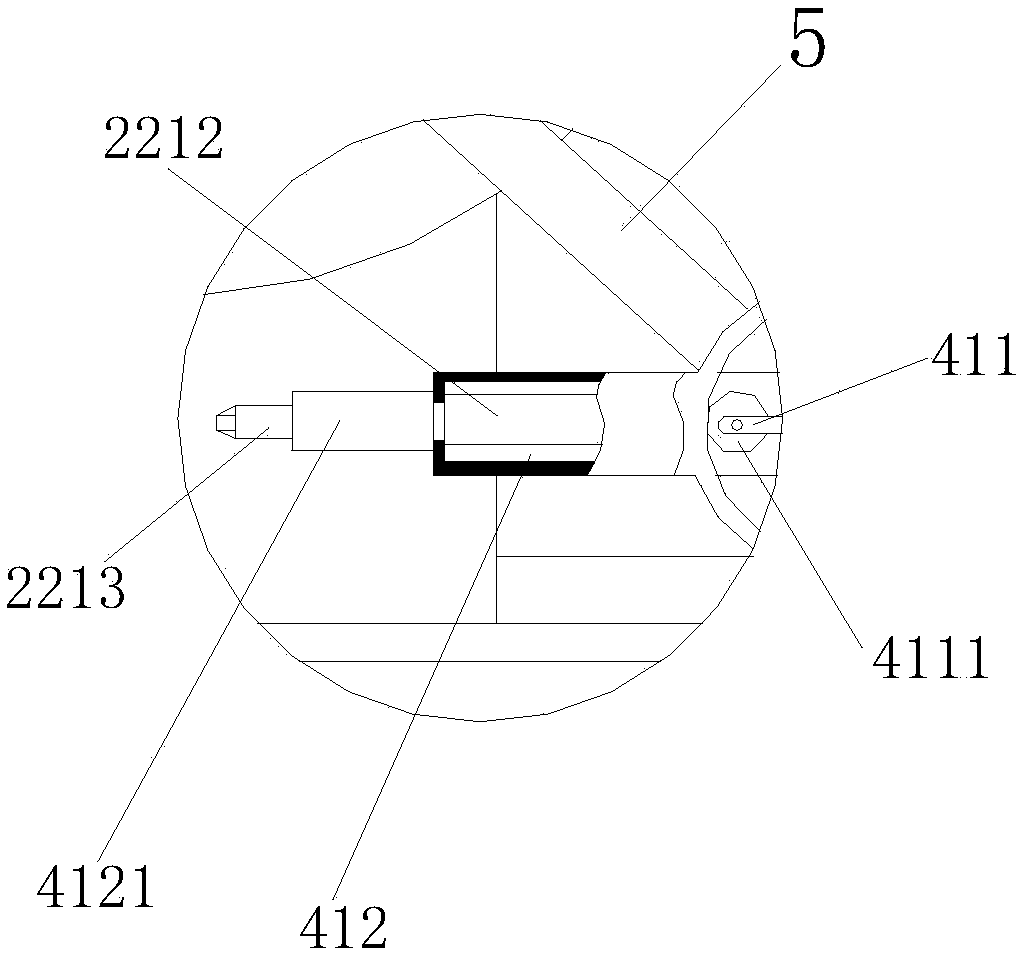

[0019] Such as figure 1 , figure 2 with image 3 As shown, the pendulum type non-equidistant polar coordinate special-shaped workpiece water jet cutting device includes a two-dimensional numerical control table 1 and an abrasive jet generating device 2, and also includes a pendulum adjustment device 3 and an axial adjustment device 4, The pendulum-type adjusting device 3 is provided with a vertical mobile platform 31, the upper end of the vertical mobile platform 31 is respectively provided with a crossbeam 311 and a stepping motor armor 312, and the lower end of the crossbeam 311 is provided with an arc rack 3111, the output shaft of the stepper motor 312 is equipped with a swing arm 5 through a flat key, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com