Vertical type assembling die assembly

A combined mold, vertical technology, applied in the direction of mold auxiliary parts, manufacturing tools, ceramic molding machines, etc., can solve the problems of large consumption of consumables, different regional amplitudes of the touch table, and large floor space, to meet the specifications and requirements. Design requirements, novel design science, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

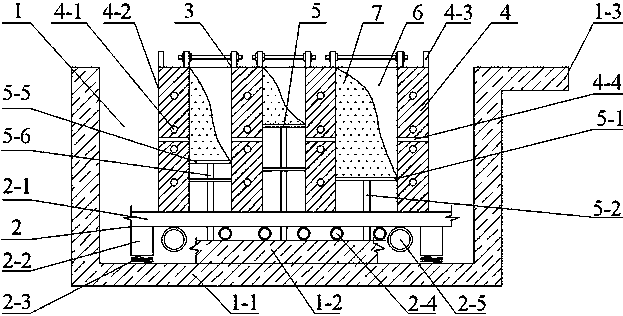

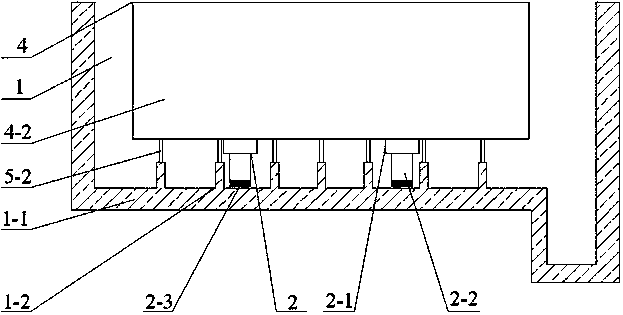

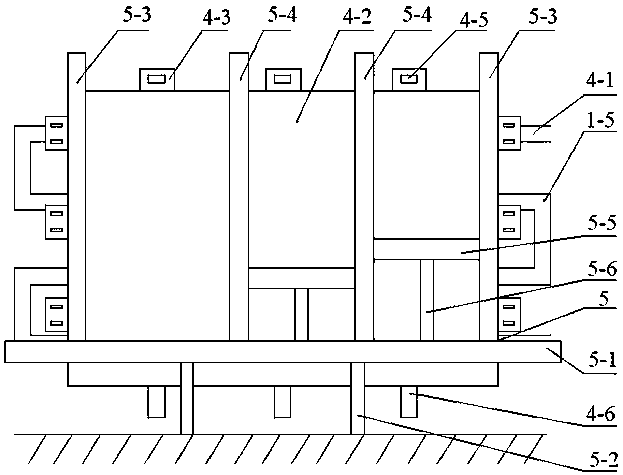

[0028] A vertical combination mold assembly, such as Figure 1-4 As shown, it includes a manger-type shell-type station 1 and a vibrating device 2 arranged in the shell-type station 1 and a vertical mold 3 arranged on the vibrating device 2. The setting of the vibrating device 2 can promote concrete in the The flow in the vertical mold 3 and the vibration of the concrete are strengthened to increase its compactness, so as to ensure that the surface of the manufactured plate member 6 is smooth, the interior is densely combined, and the product quality is guaranteed.

[0029] The shell-type workstation 1 can be built on the ground, underground or semi-underground, and the material can be steel or other building materials. The top of the shell-type station 1 is provided with an operating platform 1-3 that is at the same height as the vertical mold 3, and the operating platform 1-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com