Kitchen waste solid-liquid separation treatment device

A solid-liquid separation and treatment device technology, applied in presses, manufacturing tools, etc., can solve problems such as inconvenient treatment, impact on the urban environment, garbage corruption, etc., and achieve the effects of convenient treatment, avoiding garbage agglomeration, and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

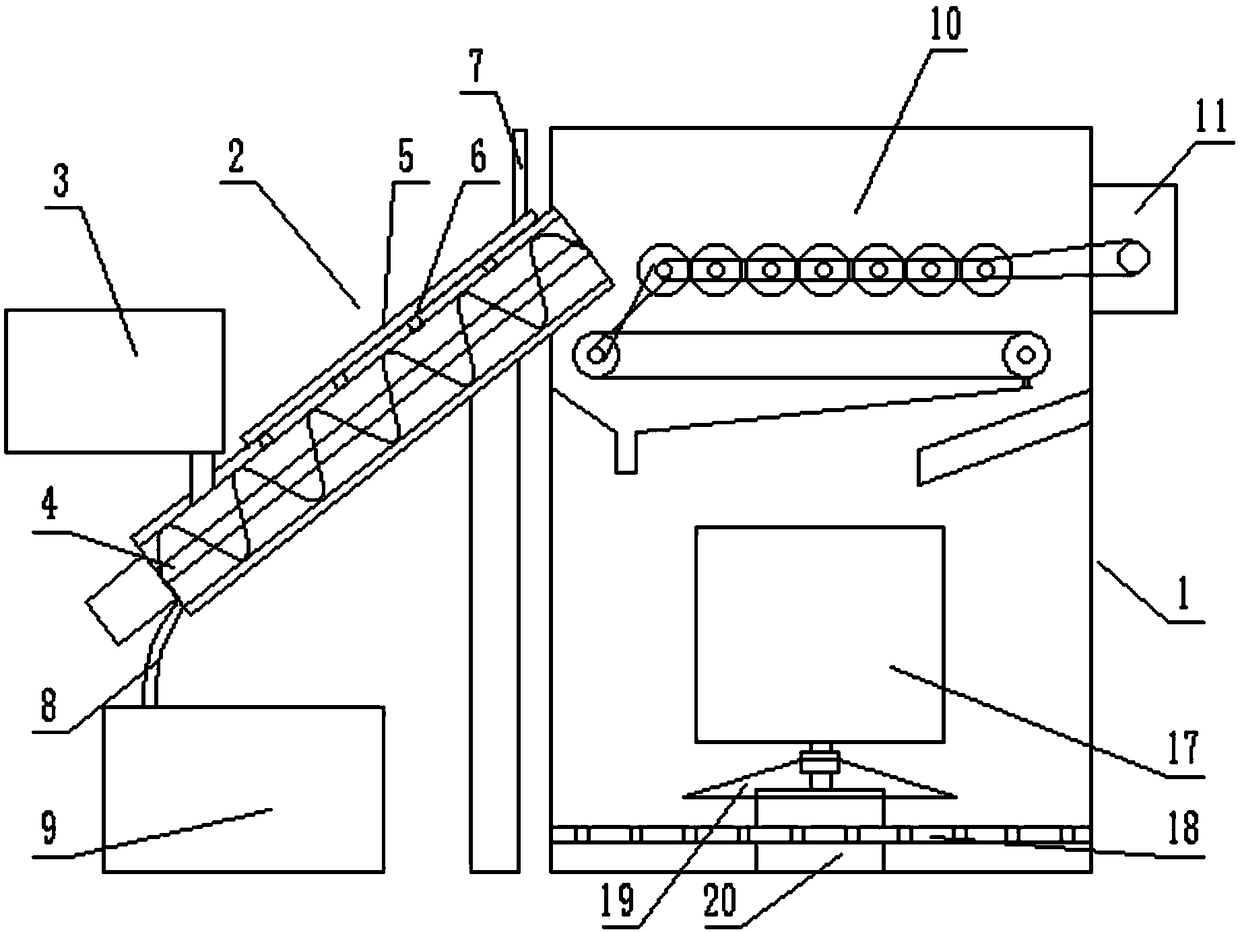

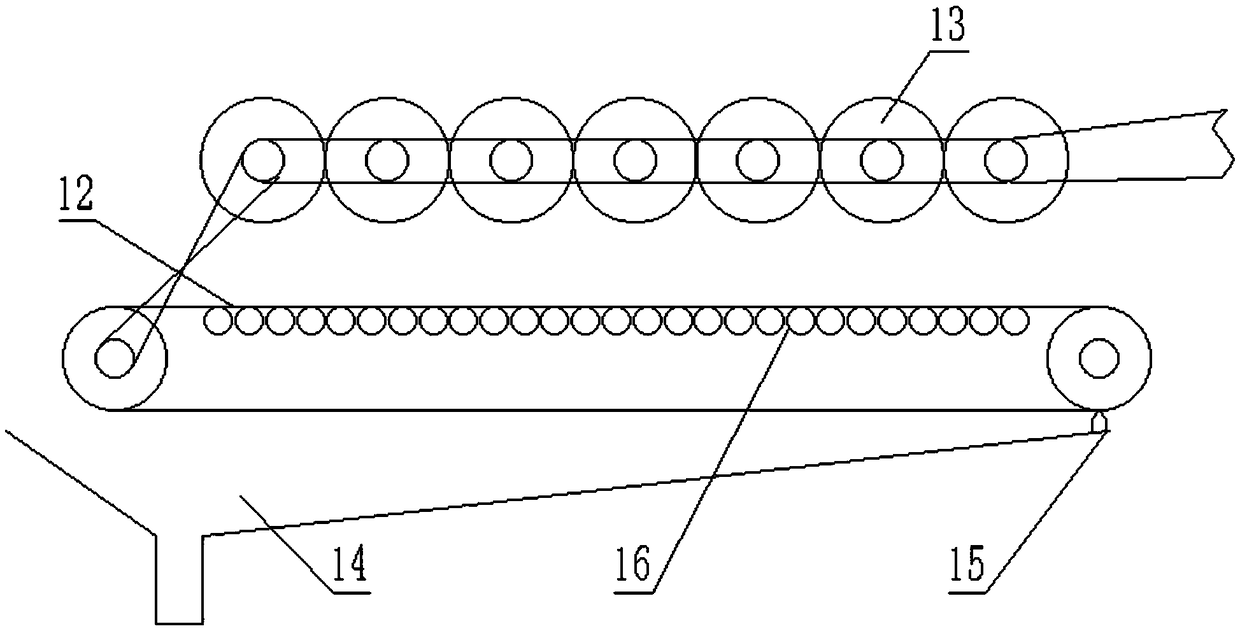

[0022] see Figure 1-3 , a solid-liquid separation treatment device for kitchen waste, comprising a feeder 2 and a dehydration tank 1, the feeder 2 is located on the side of the dehydration tank 1, the feeder 2 has a conveying cylinder arranged obliquely, and feeds The upper end of the device 2 extends into the inside of the dehydration tank 1 and communicates with the inside of the dehydration tank 1, and the lower end of the feeder 2 is connected with a dustbin 3, and the upper part of the dehydration tank 1 is provided with a dehydration conveyor 10, and the dehydration conveyor 10 It includes a conveyor belt 12 arranged in the horizontal direction and a plurality of squeeze rollers 13 arranged side by side above the conveyor belt 12, and the plurality of squeeze rollers 13 are connected by transmission belt transmission, and when one of the squeeze rollers 13 rotates, the remaining squeeze rollers 13 also Rotating in the same direction synchronously, the squeeze roller 13 ...

Embodiment 2

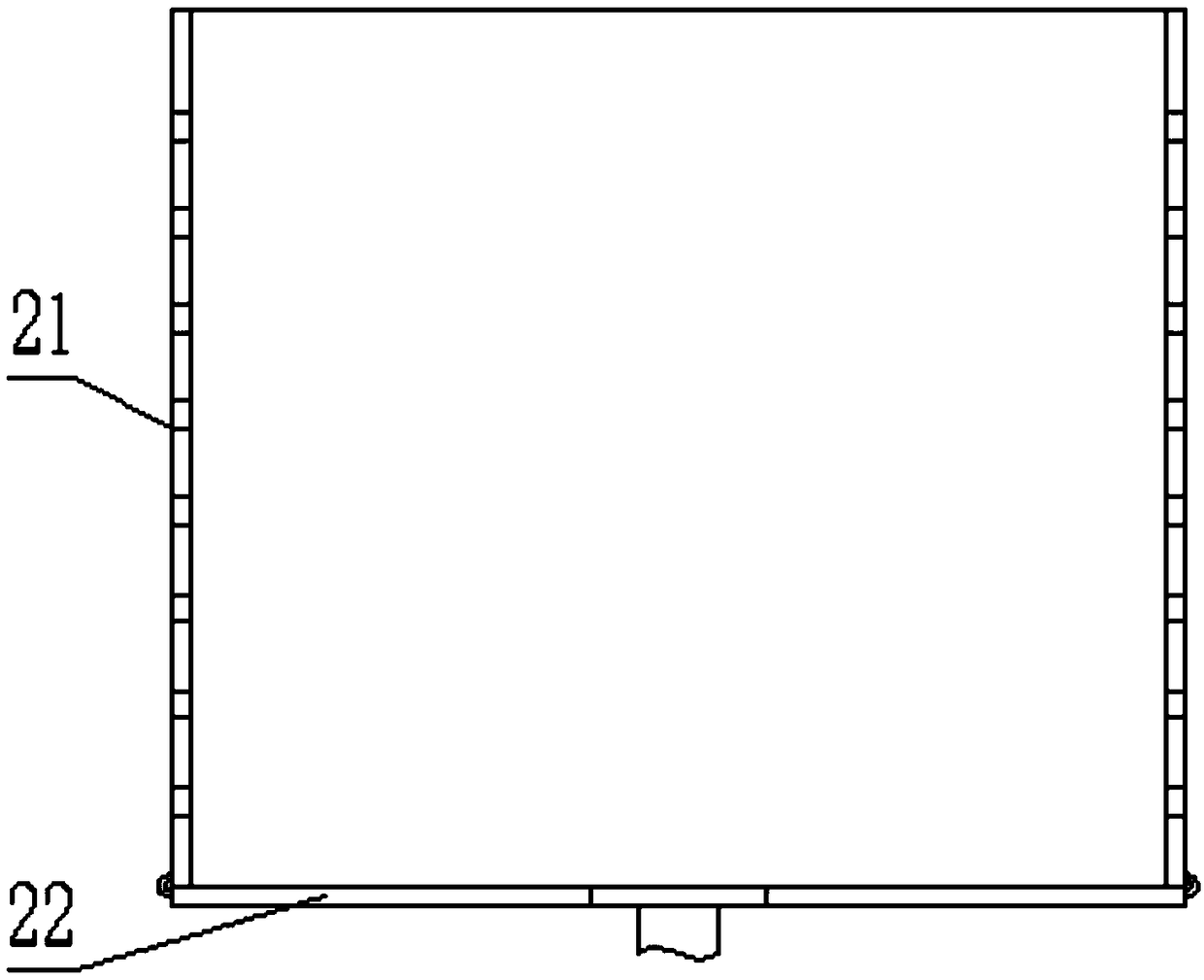

[0029]The difference from Embodiment 1 is that an umbrella cover 19 is also provided in the dehydration box 1, and the umbrella cover 19 is located below the dehydration cylinder 17, and the umbrella cover 19 is in the shape of a circular cone whose diameter gradually increases downwards. After opening the dehydration cylinder 17 and carrying out the discharge of the garbage, the garbage is guided to the dividing plate 18 by the umbrella cover 19, so as to avoid the power chassis 20 from being polluted by the garbage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com