New energy mining automobile electrical system

An electrical system and new energy technology, applied in electric braking systems, electric vehicles, collectors, etc., can solve the problems of poor road and mine, cost consumption, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

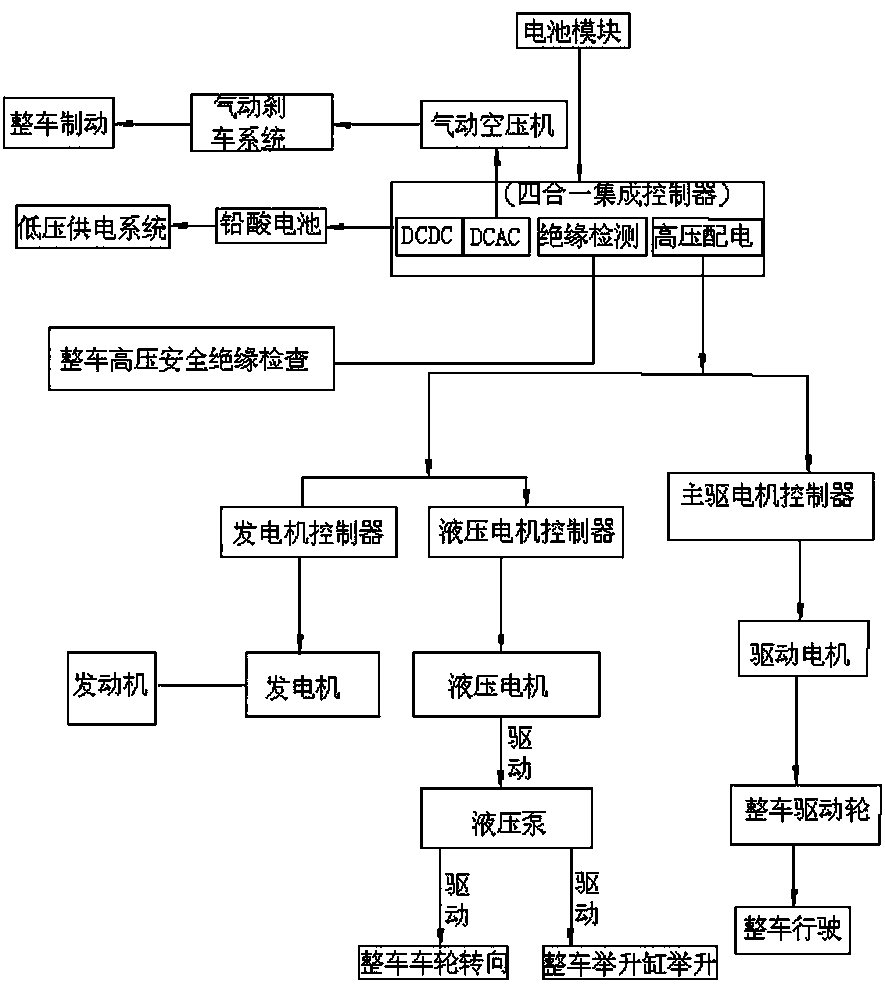

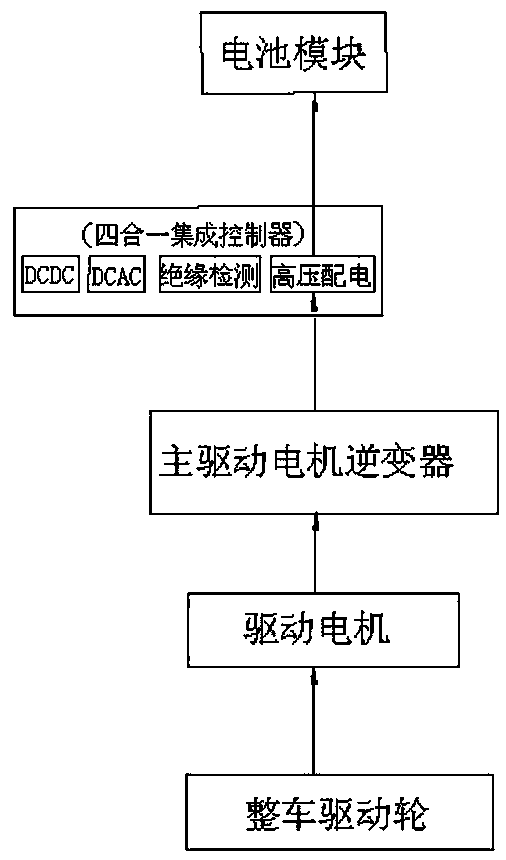

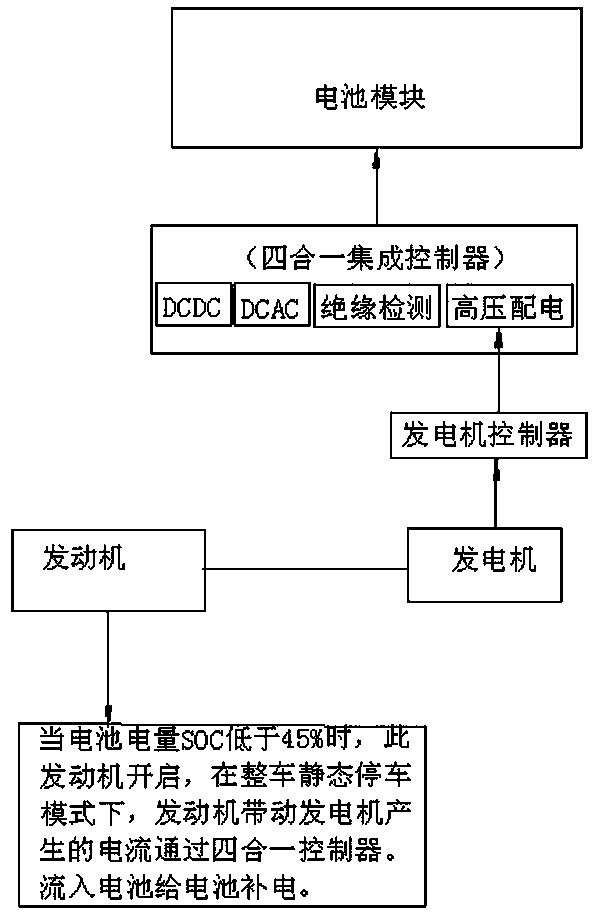

[0029] The present invention as Figure 1-3 Shown:

[0030] The electrical system of the new energy mining vehicle, including the engine, the engine is connected to a generator, and then connected to the generator controller;

[0031] It also includes the wheel steering system of the whole vehicle and the lifting system of the whole vehicle. These two systems are driven by the hydraulic pump to the hydraulic motor, and the hydraulic motor is controlled by the hydraulic motor controller; the generator controller and the hydraulic motor controller are connected to the four-in-one One integrated controller, the four-in-one integrated controller includes DCDC module, DCAC module, insulation monitoring module, and high-voltage power distribution module; the generator controller and hydraulic motor controller are connected to the four-in-one integrated controller high-voltage power distribution module;

[0032] It also includes the driving system of the whole vehicle, which is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com