Municipal sewage discharge system with detection function

A municipal sewage and discharge system technology, applied in the direction of water/sewage treatment, control/manipulation system, oxidized water/sewage treatment, etc. Good detection and early warning institutions and other issues to achieve the effect of increasing sustainable development, improving recycling, and increasing environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

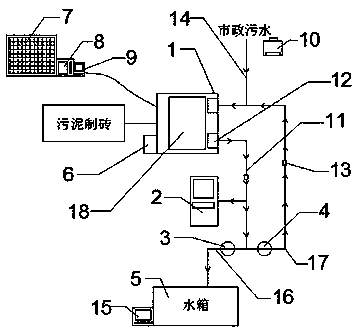

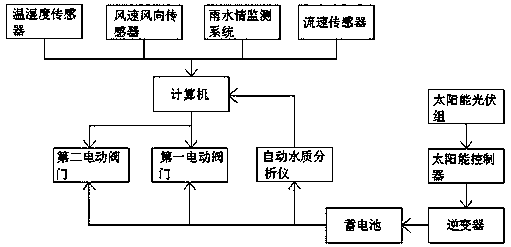

[0020] Such as Figure 1-2 As shown, a municipal sewage discharge system with detection function includes a sewage treatment tank 1, an automatic water quality analyzer 2, a first electric valve 3, a second electric valve 4 and a municipal sewage pipe 14, and one end of the municipal sewage pipe 14 It is connected with the sewage treatment pool 1, and the water outlet on one side of the sewage treatment pool 1 is connected with the shunt pipe 11 through the water pump 12. The side of the bottom of the shunt pipe 11 has a first discharge port 16, and the bottom of the first discharge port 16 is connected to The water storage tank 5, the other side of the bottom of the shunt pipe 11 has a second discharge port 17, and the second discharge port 17 is connected to the water inlet of the sewage treatment tank 1, and the first electric valve is set on the first discharge port 16 3. A second electric valve 4 is set on the second discharge port 17, one side of the shunt pipe 11 is con...

Embodiment 2

[0027] Such as Figure 1-2 As shown, a municipal sewage discharge system with detection function includes a sewage treatment tank 1, an automatic water quality analyzer 2, a first electric valve 3, a second electric valve 4 and a municipal sewage pipe 14, and one end of the municipal sewage pipe 14 It is connected with the sewage treatment pool 1, and the water outlet on one side of the sewage treatment pool 1 is connected with the shunt pipe 11 through the water pump 12. The side of the bottom of the shunt pipe 11 has a first discharge port 16, and the bottom of the first discharge port 16 is connected to The water storage tank 5, the other side of the bottom of the shunt pipe 11 has a second discharge port 17, and the second discharge port 17 is connected to the water inlet of the sewage treatment tank 1, and the first electric valve is set on the first discharge port 16 3. A second electric valve 4 is set on the second discharge port 17, one side of the shunt pipe 11 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com