Mud balance system and control method based on the height difference measuring instrument inside and outside the borehole

A technology of mud balance and control method, which is applied in the field of bored piles, can solve the problems of inconvenient assembly, harsh working environment of bored piles, and low degree of automation, so as to improve the accuracy of measurement, high recycling rate, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

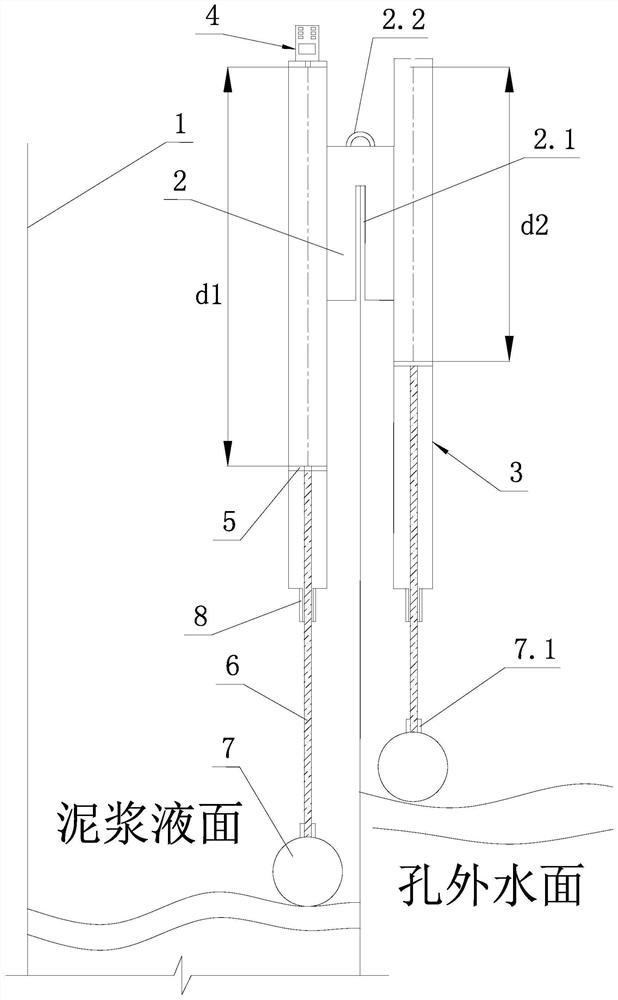

[0036] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is based on the mud balance system of the height difference measuring instrument inside and outside the borehole, which includes a measuring device and a mud circulation device.

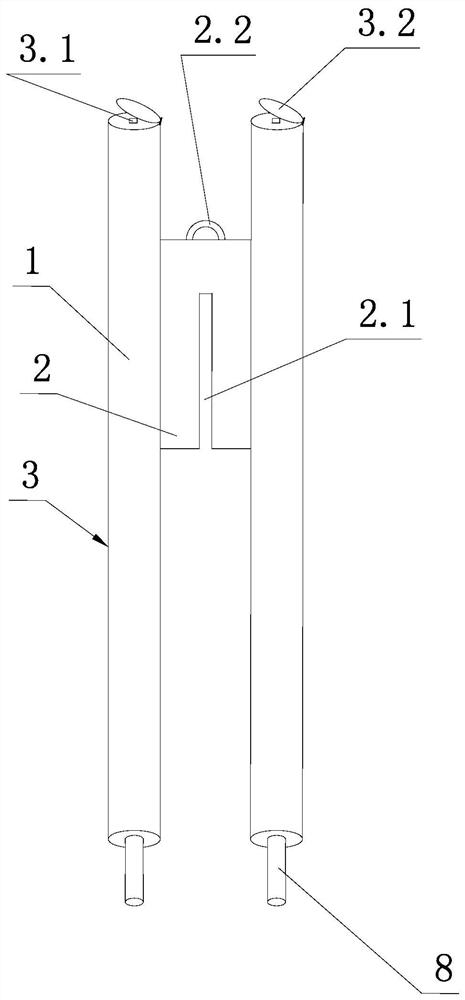

[0037] The measuring device includes a connecting flap 2 for connecting with the drilled casing 1, the lower part of the connecting flap 2 is provided with a card slot 2.1 for clamping with the side wall of the casing 1; the upper part of the connecting flap 2 is provided with a lifting ring 2.2.

[0038] The inner side of the connecting wing 2 is welded with a sleeve 3 for measuring the height of the mud level in the borehole, and the outer side of the connecting wing 2 is welded with a sleeve 3 for measuring the height of the water level outside the borehole.

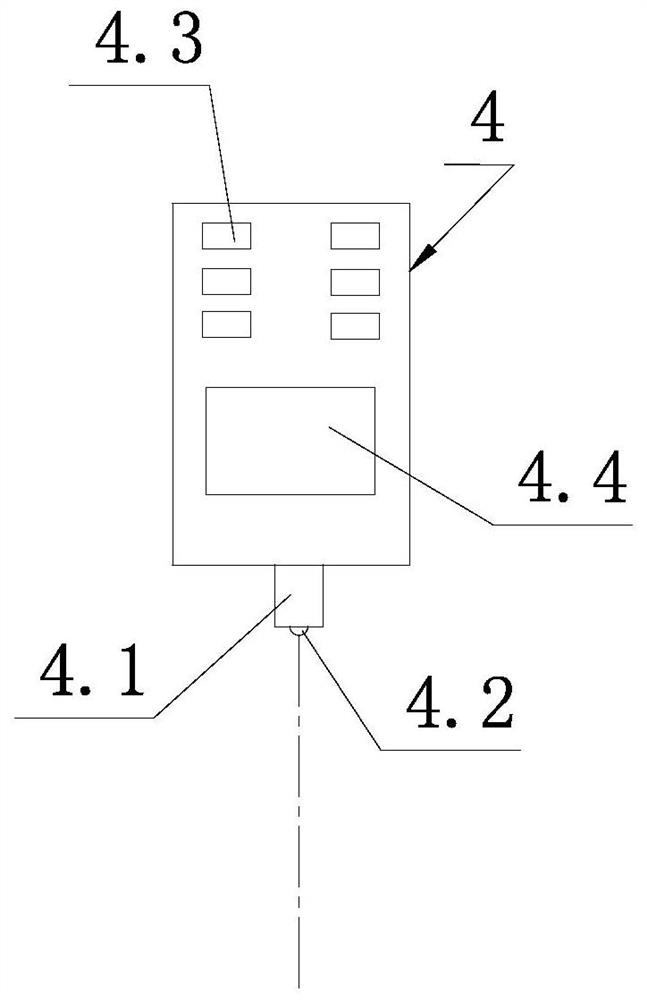

[0039] The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com