Rubber coated anchor chain, and preparation method thereof

An anchor chain and rubber technology, which is applied in the direction of ships and coatings, can solve the problems of reduced resistance of the entire chain, shortened service life, and reduced tensile strength, so as to reduce wear, increase service life, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

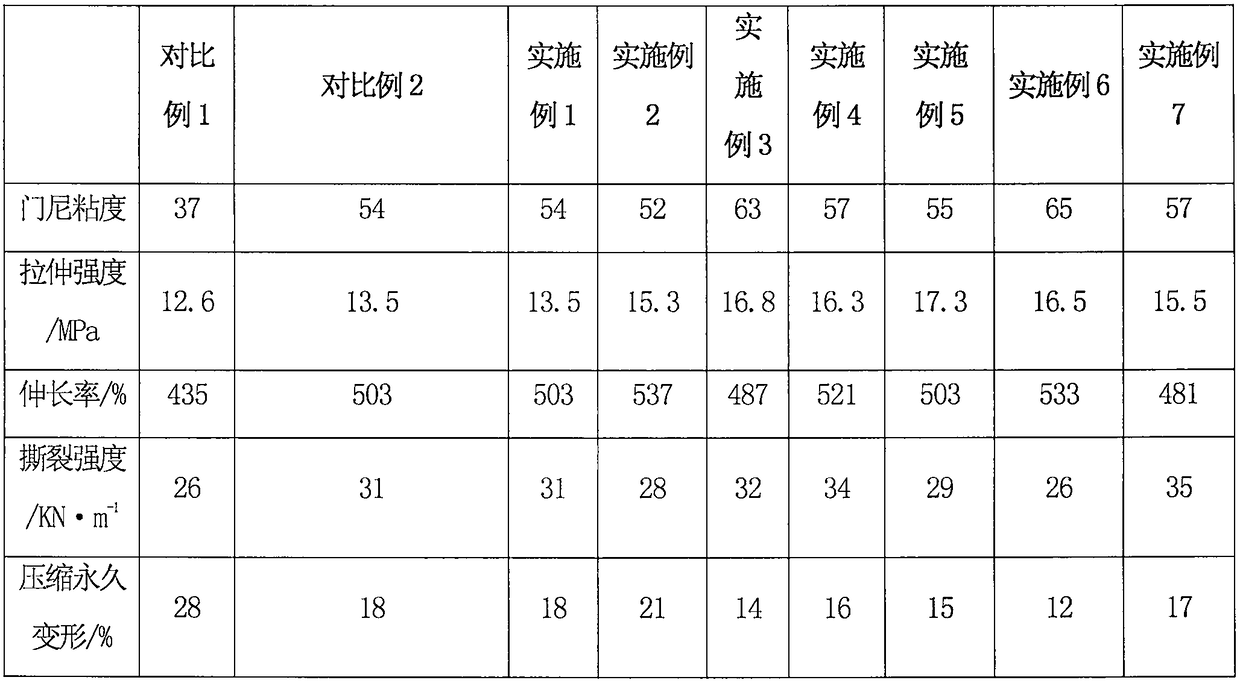

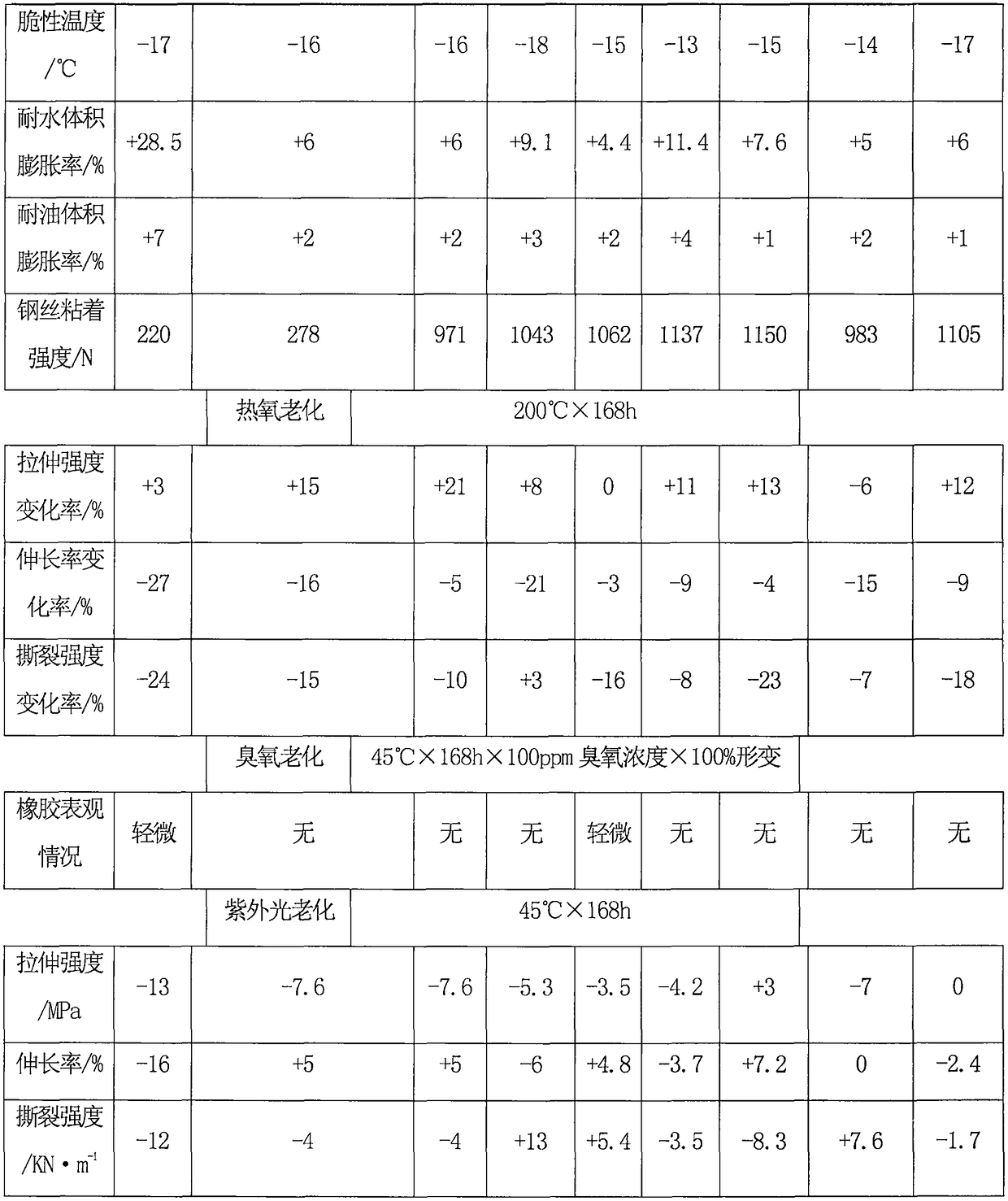

Examples

Embodiment 1

[0075] This embodiment provides a rubber-coated anchor chain, which includes an anchor chain skeleton made of metal and a rubber cladding. The anchor chain skeleton is a solid iron structure, and a plurality of strip-shaped slots are arranged on the outer circumference. The groove width is 3mm, and the depth is 3mm, and the whole anchor skeleton is covered by rubber cladding.

[0076] The rubber-coated anchor chain is prepared by the following method:

[0077] (1) Carry out high-temperature heating in the high-temperature furnace of the steel material of blanking specifications required by the process;

[0078] (2) The heat-treated bar is bent and formed into an anchor chain skeleton through the pull ring equipment, and sawtooth grooves are cut on the anchor chain skeleton, and each anchor chain skeleton is interlocked with each other, and then processed into a craft Anchor chains requiring number of links;

[0079] (3) Use welding equipment to weld the bent joints of each c...

Embodiment 2

[0102] This embodiment provides a rubber-coated anchor chain, which includes an anchor chain skeleton made of metal and a rubber cladding. The anchor chain skeleton is a solid iron structure, and a plurality of strip-shaped slots are arranged on the outer circumference. The groove width is 6mm, and the depth is 5mm, and the whole anchor skeleton is covered by rubber cladding.

[0103] The rubber cladding is prepared by the following method:

[0104] (1) Carry out high-temperature heating in the high-temperature furnace of the steel material of blanking specifications required by the process;

[0105] (2) The heat-treated bar is bent and formed into an anchor chain skeleton through the pull ring equipment, and sawtooth grooves are cut on the anchor chain skeleton, and each anchor chain skeleton is interlocked with each other, and then processed into a craft Anchor chains requiring number of links;

[0106] (3) Use welding equipment to weld the bent joints of each chain link; ...

Embodiment 3

[0129] This embodiment provides a rubber-coated anchor chain, which includes an anchor chain skeleton made of metal and a rubber cladding. The anchor chain skeleton is a solid iron structure, and a plurality of strip-shaped slots are arranged on the outer circumference. The groove width is 10mm, and the depth is 5mm, and the whole anchor skeleton is covered by rubber cladding.

[0130] The rubber cladding is prepared by the following method:

[0131] (1) Carry out high-temperature heating in the high-temperature furnace of the steel material of blanking specifications required by the process;

[0132] (2) The heat-treated bar is bent and formed into an anchor chain skeleton through the pull ring equipment, and sawtooth grooves are cut on the anchor chain skeleton, and each anchor chain skeleton is interlocked with each other, and then processed into a craft Anchor chains requiring number of links;

[0133] (3) Use welding equipment to weld the bent joints of each chain link;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com