A method for surface sealing of polyester yarn fabric base fabric

A polyester yarn and fabric technology, which is applied in the inspection of textile materials, textiles, textiles and papermaking, etc. It can solve problems such as difficult to achieve sealing effect and surface mottling, so as to avoid uneven and rough surface and good hanging aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for surface sealing of a polyester yarn fabric base cloth, comprising the steps of:

[0020] S1. Use 100% polyester yarn fabric as the base fabric;

[0021] S2, the base fabric is processed through the weft adjusting machine, so that the weft yarn and the warp yarn intersect vertically within the entire width of the door;

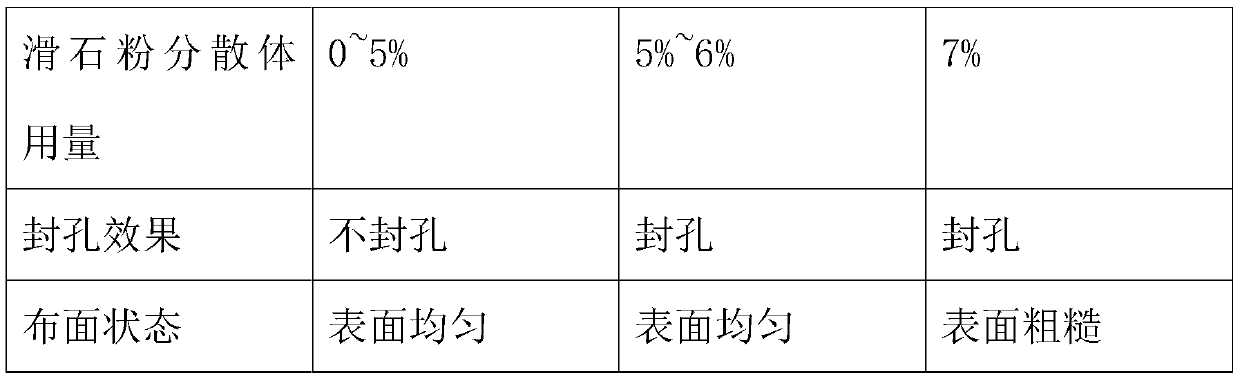

[0022] S3. Scrape the color glue on the front of the base fabric after weft adjustment, and perform the first drying treatment to form the front color glue layer; scrape the color glue on the back side of the base fabric, and perform the second drying treatment; The glue is made by mixing 50 parts by weight of acrylic emulsion, 45.5 parts of water and 4.5 parts of talcum powder dispersion, and stirring for 25 minutes; Set at 160°C.

[0023] Wherein, the formula of the talcum powder dispersion is composed of 55.8 parts by weight of silicate, 0.2 parts of dispersant and 44.0 parts of water. In order to achieve the best effect, the timing of...

Embodiment 2

[0026] A method for surface sealing of a polyester yarn fabric base cloth, comprising the steps of:

[0027] S1. Use 100% polyester yarn fabric as the base fabric;

[0028] S2, the base fabric is processed through the weft adjusting machine, so that the weft yarn and the warp yarn intersect vertically within the entire width of the door;

[0029] S3. Scrape the color glue on the front of the base cloth, and perform the first drying treatment to form the front color glue layer; scrape the color glue on the back side of the base cloth, and perform the second drying treatment; the color glue is determined by weight 49.7 parts of acrylic emulsion, 45 parts of water and 5.3 parts of talcum powder dispersion were mixed and stirred for 30 minutes; the temperature of the first drying treatment and the second drying treatment were both set at 160°C .

[0030] Wherein, the formula of the talc powder dispersion is composed of 55.4 parts by weight of silicate, 0.6 part of dispersant and...

Embodiment 3

[0033] A method for surface sealing of a polyester yarn fabric base cloth, comprising the steps of:

[0034] S1. Use 100% polyester yarn fabric as the base fabric;

[0035] S2, the base fabric is processed through the weft adjusting machine, so that the weft yarn and the warp yarn intersect vertically within the entire width of the door;

[0036] S3. Scrape the color glue on the front of the base cloth, and perform the first drying treatment to form the front color glue layer; scrape the color glue on the reverse side of the soaked base cloth, and perform the second drying treatment; The color glue is made by mixing 50 parts by weight of acrylic emulsion, 44.5 parts of water and 5.5 parts of talcum powder dispersion, and stirring for 35 minutes; Set at 160°C.

[0037] Wherein, the formula of the talcum powder dispersion is composed of 55.6 parts by weight of silicate, 0.8 part of dispersant and 43.6 parts of water. In order to achieve the best effect, the timing of adding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com