Preparation method of dinner plate primary product

A manufacturing method and technology of primary products, which are applied in the field of primary product manufacturing of dinner plates, can solve problems such as poor continuity, poor forming quality of primary plate products, and unreasonable design of primary plate products, etc., so as to achieve the effect of improving the forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will now be described with reference to the accompanying drawings, in which similar element numbers represent similar elements.

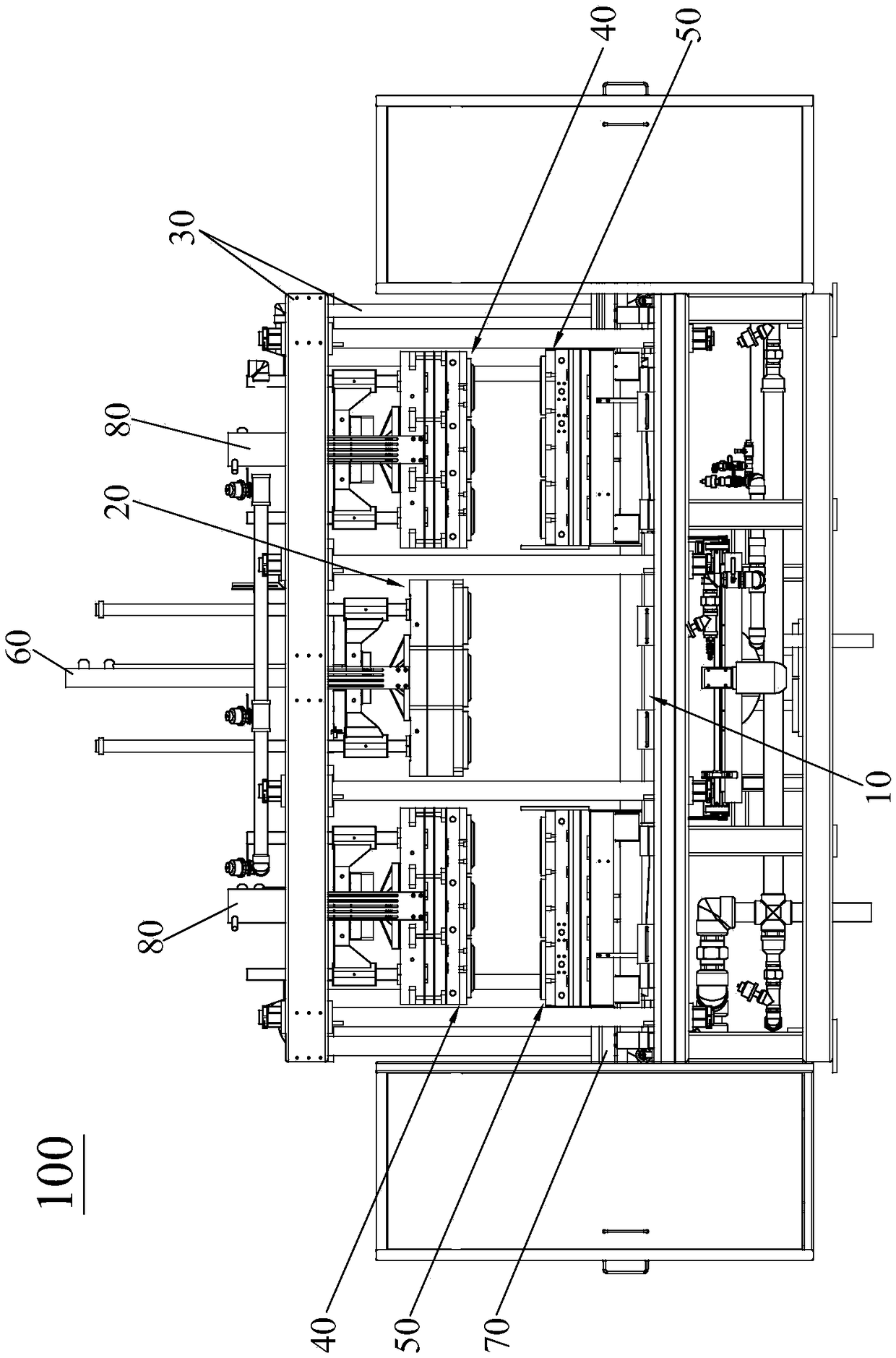

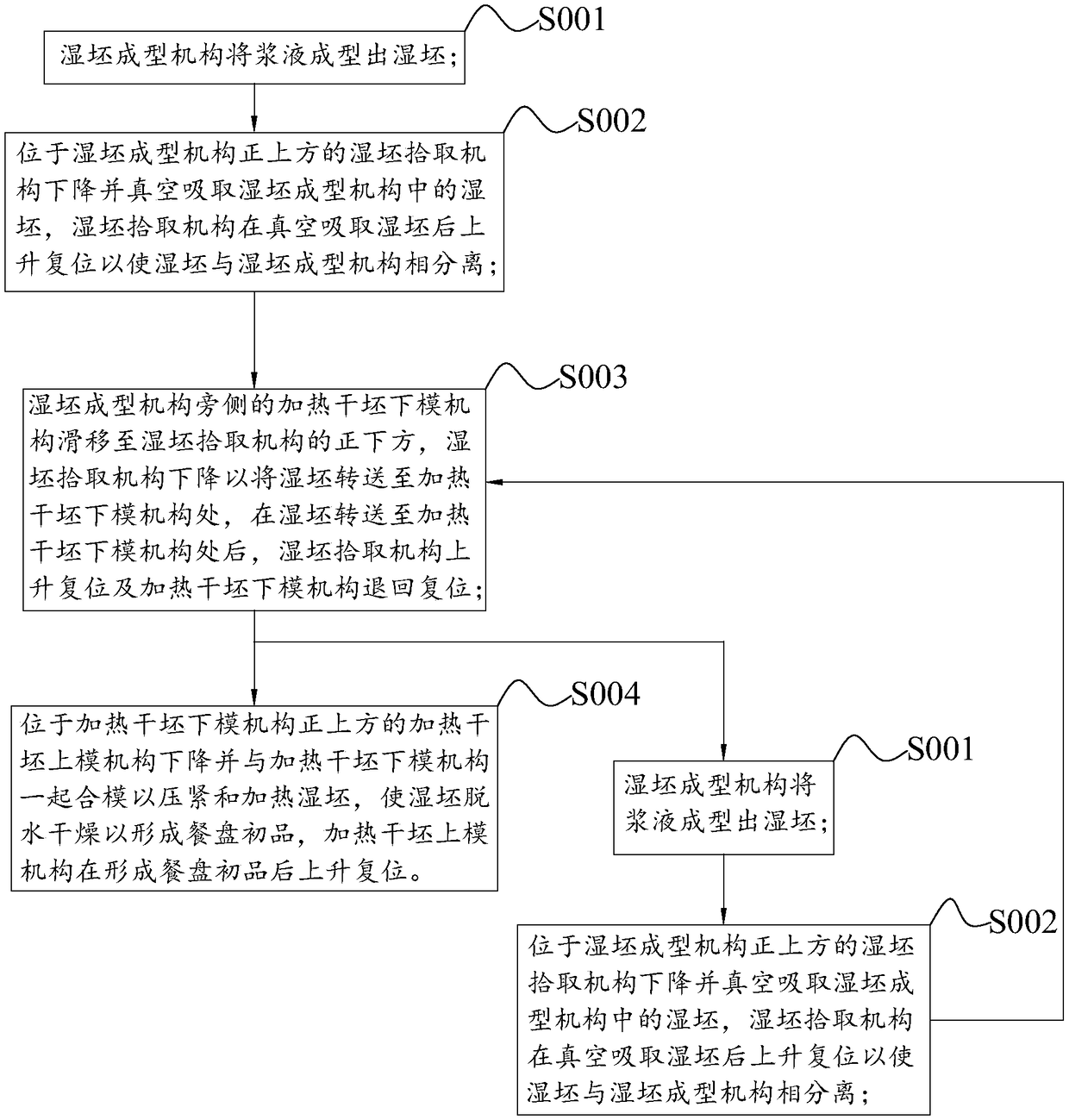

[0019] Such as figure 1 As shown, the preliminary plate forming machine 100 for implementing the method for manufacturing the preliminary plate of the present invention includes a wet blank forming mechanism 10, a wet blank pickup mechanism 20, a frame 30, a heated dry blank upper mold mechanism 40, and a heated dry blank lower The mold mechanism 50, the first driver 60, the second driver 70, and the third driver 80. The wet billet forming mechanism 10 is installed on the frame 30, the wet billet picking mechanism 20 is slidably arranged on the frame 30 along the vertical direction of the frame 30, and the wet billet picking mechanism 20 is also located directly above the wet billet forming mechanism 10. The first driver 60 is installed on the frame 30 and is used to drive the wet billet picking mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com