OLED display panel and manufacturing method thereof and OLED display device

A display panel and display substrate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of uneven display brightness and increased cathode resistance of OLED display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

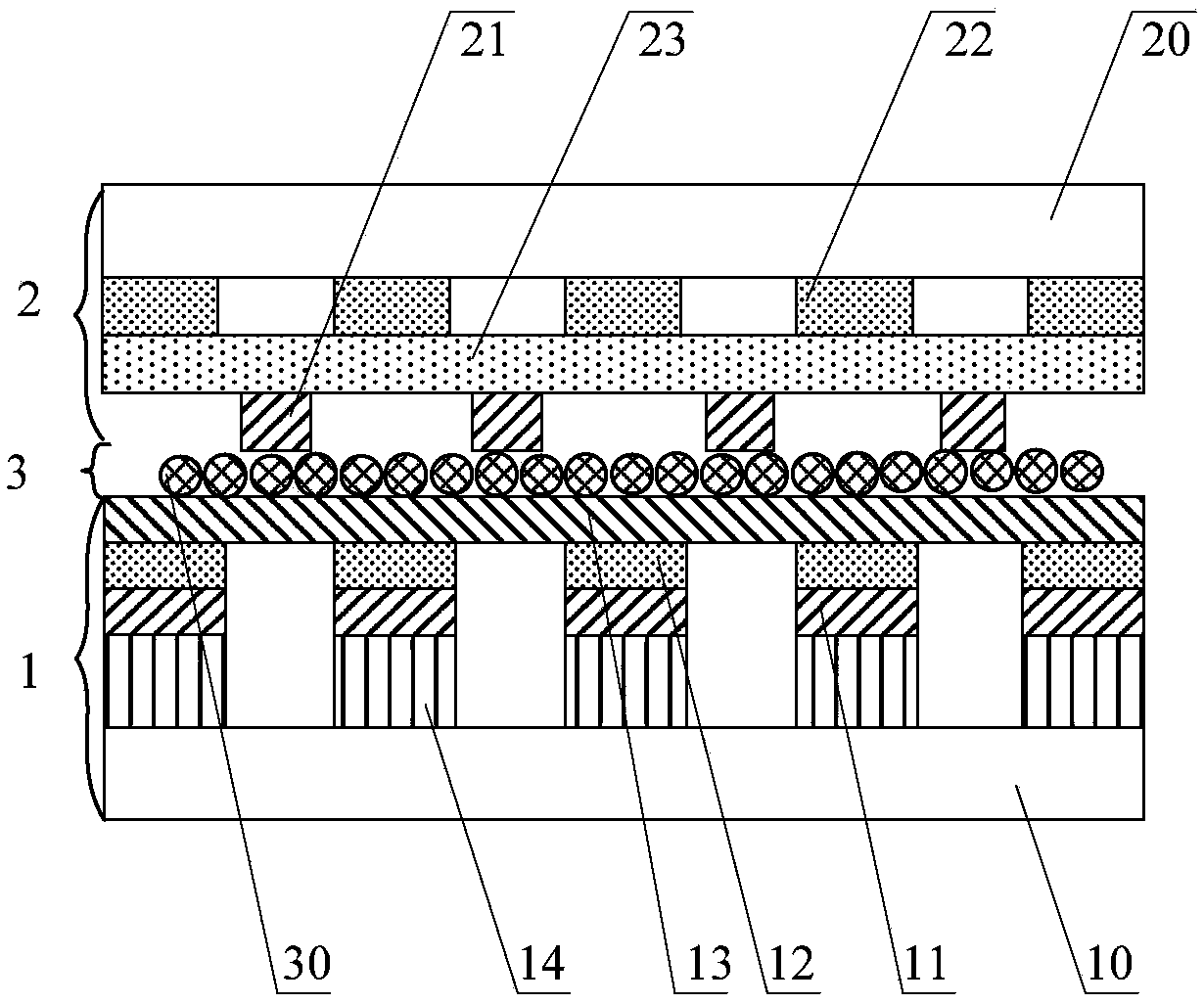

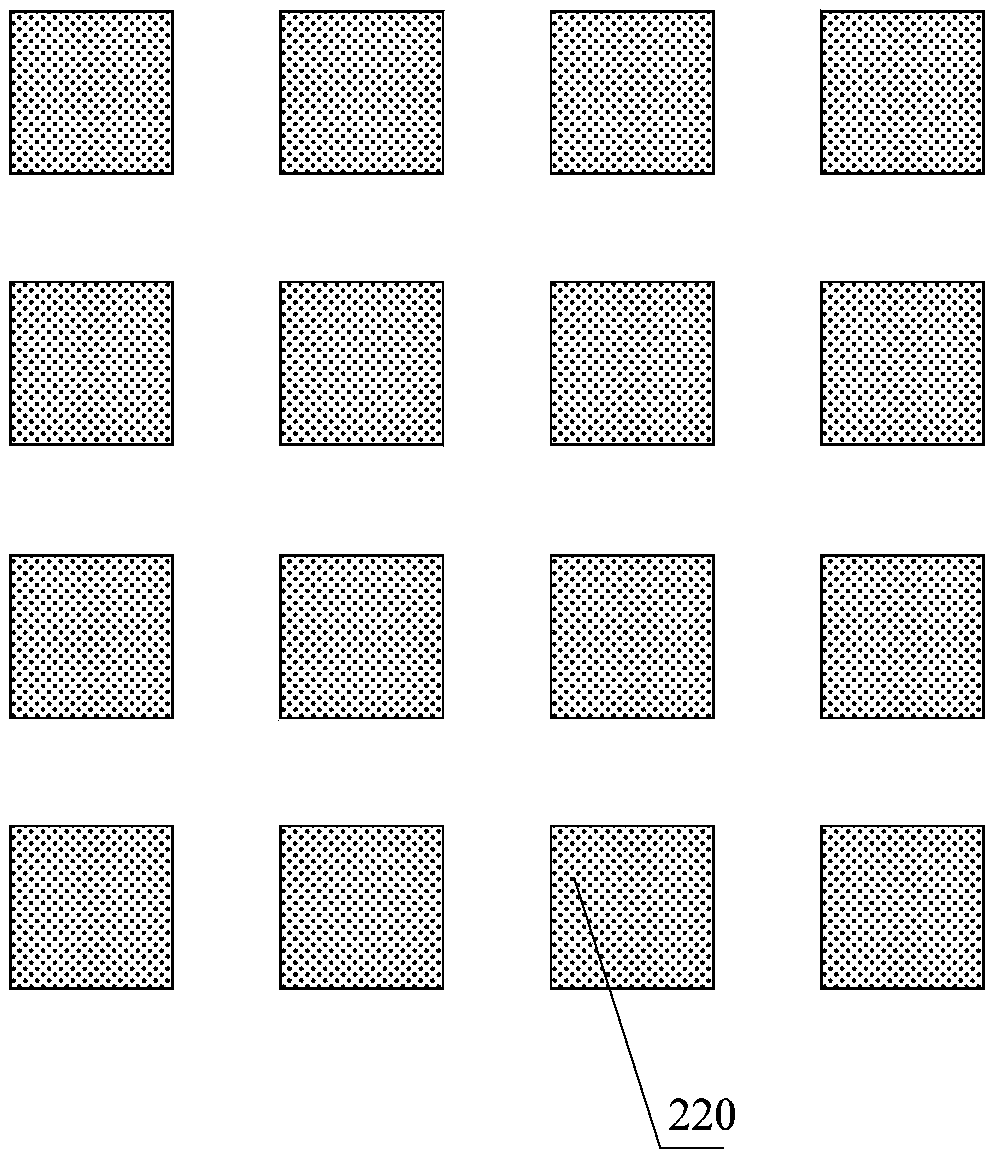

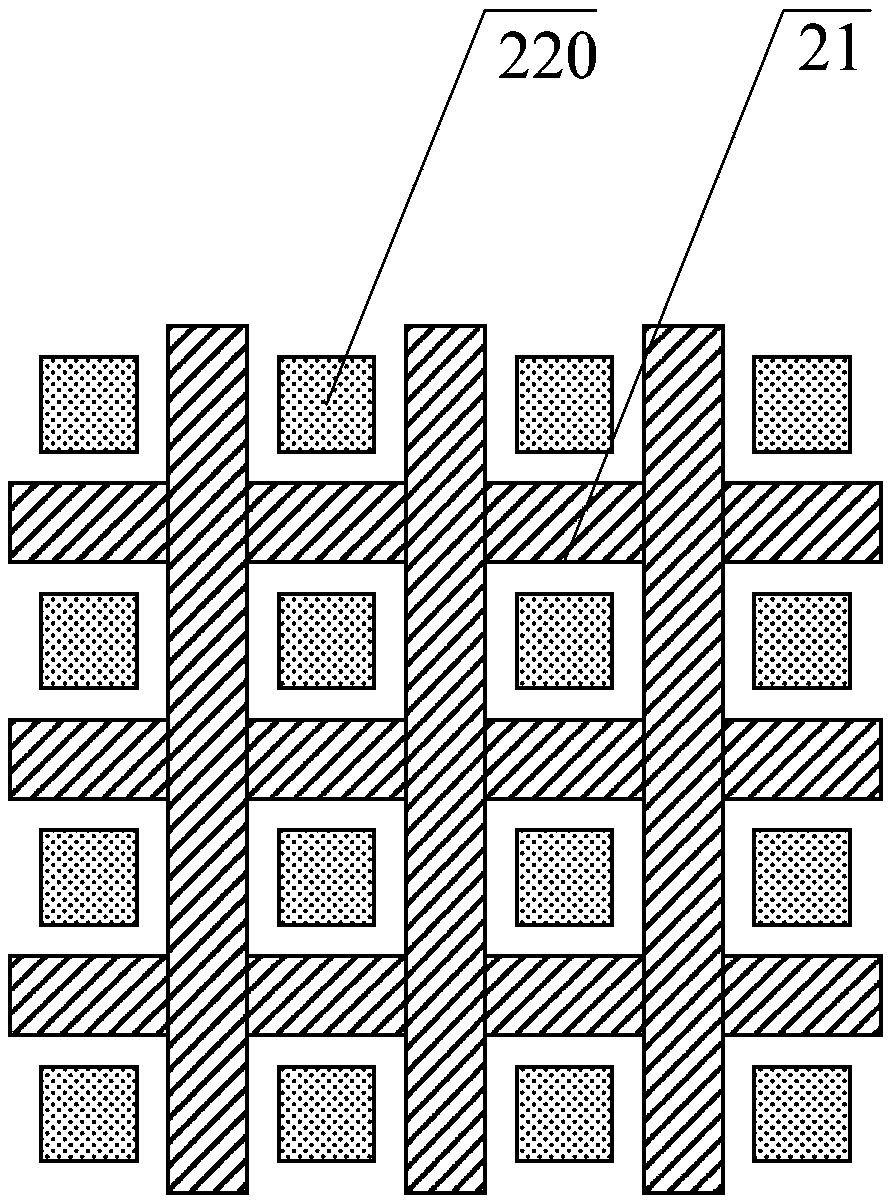

[0069] figure 1 Schematic structure of the OLED display panel provided for the embodiment of the present invention Figure 1 ,Such as figure 1 As shown, the OLED display panel provided by the embodiment of the present invention includes: an OLED display substrate 1 and an encapsulation substrate 2 arranged oppositely; the OLED display substrate 1 includes: a first substrate 10 and first electrodes 11 sequentially arranged on the first substrate , the organic light-emitting layer 12 and the second electrode 13; the encapsulation substrate 2 includes: a second substrate 20 and a conductive layer 21 arranged on the second substrate 20; the surface of the OLED display substrate 1 provided with the second electrode 13 is arranged with the encapsulation substrate 2 The surfaces with the conductive layer 21 are bonded by bonding glue 3 .

[0070] Wherein, the bonding glue 3 includes conductive particles 30 , and the conductive layer 21 is electrically connected to the second electr...

Embodiment 2

[0104] Based on the inventive concepts of the above embodiments, the embodiments of the present invention also provide a method for manufacturing an OLED display panel, Figure 7 The flow chart of the OLED display panel manufacturing method provided by the embodiment of the present invention, such as Figure 7As shown, the OLED display panel manufacturing method provided by the embodiment of the present invention specifically includes the following steps:

[0105] Step 100, providing a first substrate.

[0106] Optionally, the first substrate can be a rigid substrate or a flexible substrate, wherein the rigid substrate can be, but not limited to, one or more of glass and metal sheets; the flexible substrate can be, but not limited to, polyethylene terephthalate Glycol esters, ethylene terephthalate, polyether ether ketone, polystyrene, polycarbonate, polyarylate, polyarylate, polyimide, polyvinyl chloride, polyethylene, textile fibers one or more of.

[0107] Step 200, sequ...

Embodiment 3

[0132] Based on the inventive concepts of the above embodiments, the embodiments of the present invention further provide an OLED display device, and the OLED display device provided in the embodiments of the present invention includes: an OLED display panel.

[0133] Wherein, the OLED display panel is the OLED display panel provided in Embodiment 1, specifically a bottom-emitting OLED display panel, and its implementation principle and implementation effect are similar, and will not be repeated here.

[0134] Specifically, the display device may be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, and a navigator, which is not limited in this embodiment of the present invention.

[0135] The drawings of the embodiments of the present invention only relate to the structures involved in the embodiments of the present invention, and other structures may refer to common d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com