Liner and liquid heating container

A liquid heating container and liner technology, used in heating devices, cooking utensils, water-boiling utensils, etc., can solve problems such as deterioration and long-term use performance of coatings that are not wear-resistant, so as to reduce heat transfer and improve bidirectional performance. Heat transfer effect, the effect of increasing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

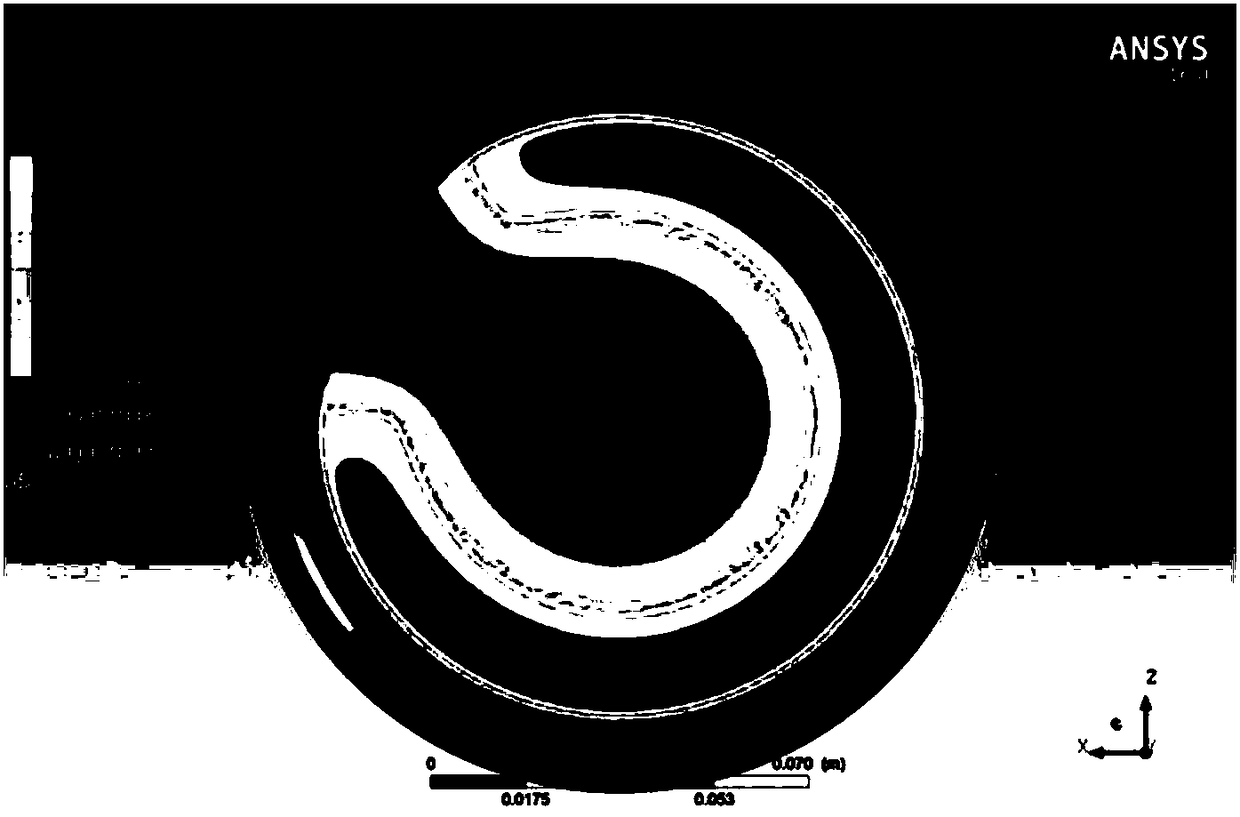

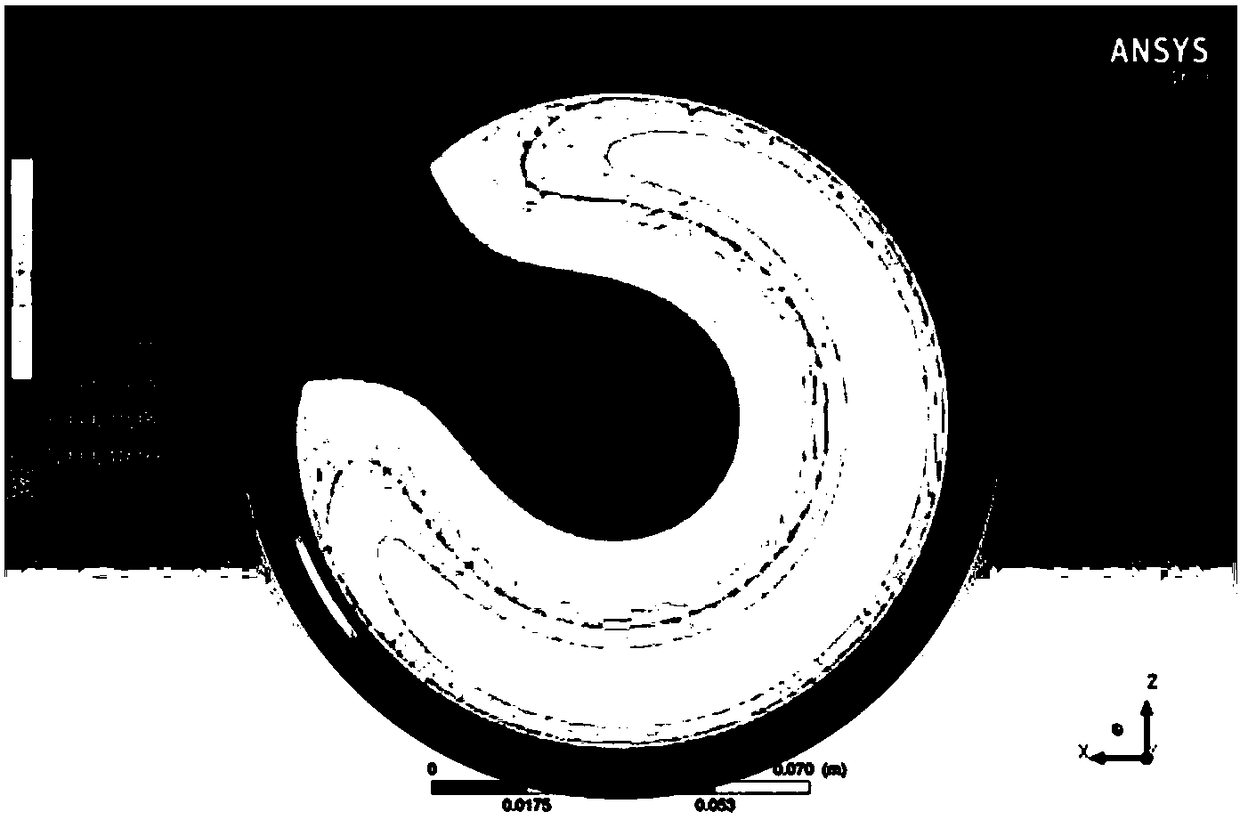

[0128] The improved electric kettle liner, the heat conduction plate is made of aluminum plate, the heating element is made of electric heating tube, the heating power P=1800W, t=4mm, L=10mm, the maximum sound power level of boiling water=60.52dB(A), and the thermal simulation results as attached Figure 11 shown.

[0129] Compared Figure 11 and Figure 10 It was found that after the improvement of the inner tank of the electric kettle, the temperature near the electric heating tube dropped by about 30°C, the thermal power density decreased significantly, and the maximum sound power level decreased by 10.04dB(A). It can be seen that by increasing t (the thickness of the heat conduction plate) and L (the maximum distance between the outer periphery of the heating element and the heat conduction plate and the outer periphery of the heat conduction plate), the noise of boiling water can be significantly reduced.

[0130] 2. Orthogonal experiment and results (the reference sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com