A kind of cationic black dye composition and its preparation and application

A technology of cationic dyes and black dyes, which is applied in cationic black dye compositions and its preparation and application fields, can solve the problems of poor color fastness, difficult dyeing depth, and low jet black, and achieve uniform coloring and deep dyeing performance Good, good composition compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

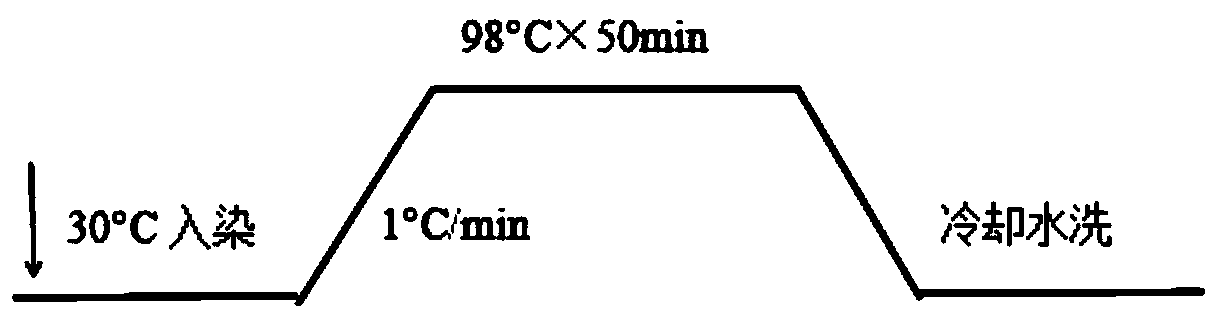

[0051] The super imitation cotton fiber used in the present embodiment is polyester fiber woven fabric (T919) density / 10cm: 570 (warp) * 290 (weft); Gram weight: 157g m -2 , provided by Zhejiang Shengfa Textile Printing and Dyeing Co., Ltd.

[0052]The specifications and manufacturers of other chemicals are shown in Table 1.

[0053] Table 1 Experimental drugs, specifications and manufacturers

[0054]

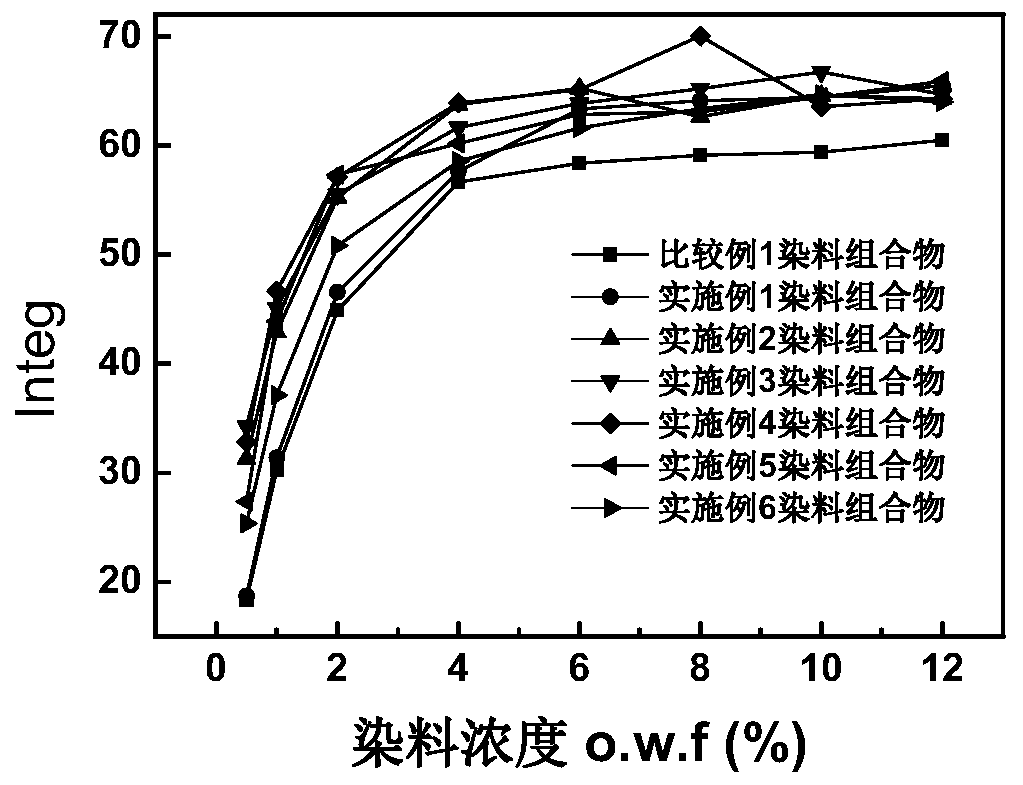

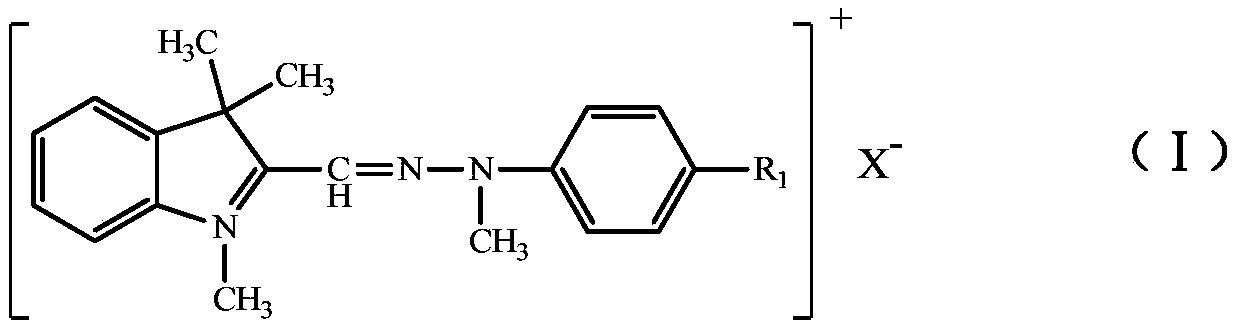

[0055] According to the data shown in Table 2, the yellow dye component such as structural formula (I), the red dye component such as structural formula (II), the blue dye component such as structural formula (III) and auxiliary agent are metered and pulverized The powder was ground into a mixer and mixed for 6 hours to obtain a cationic black dye composition.

[0056] Table 2

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com