Drilling fluid flow pattern regulator, and preparation method and applications thereof

A technology of flow regulator and drilling fluid, which is applied in the field of oil drilling, can solve problems such as lack of water retention capacity, and achieve the effects of enhancing shear dilution, preventing water loss, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

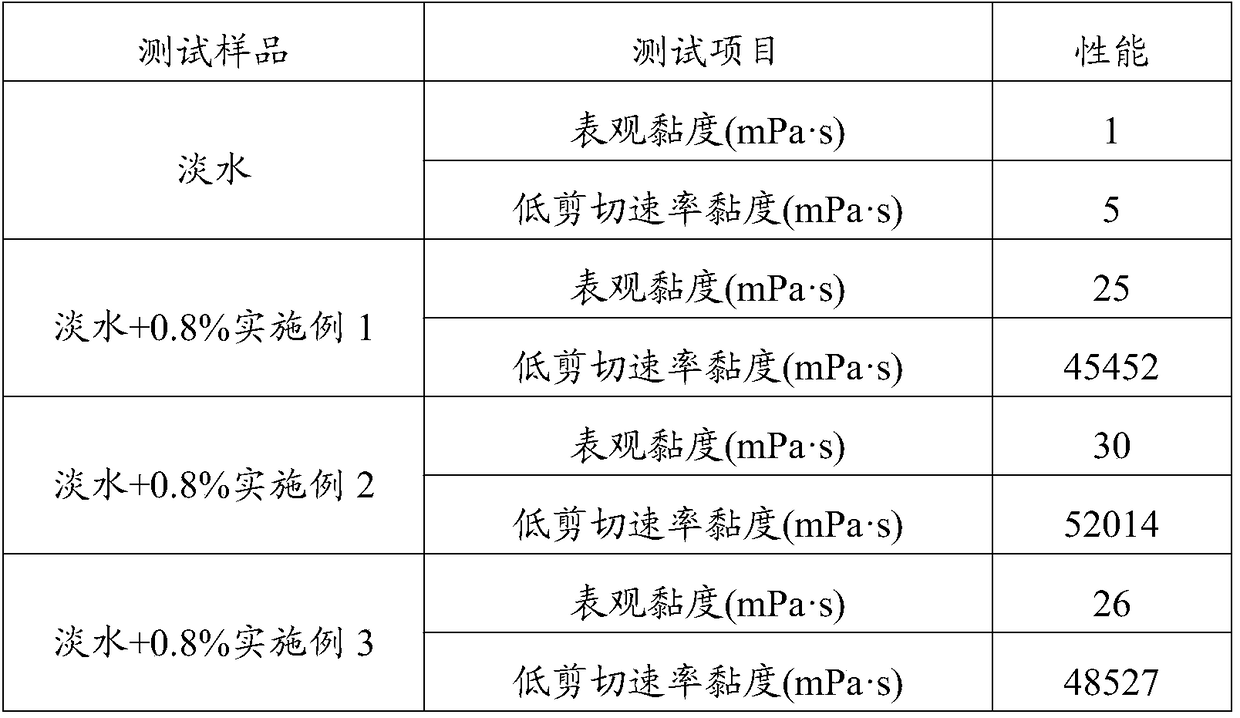

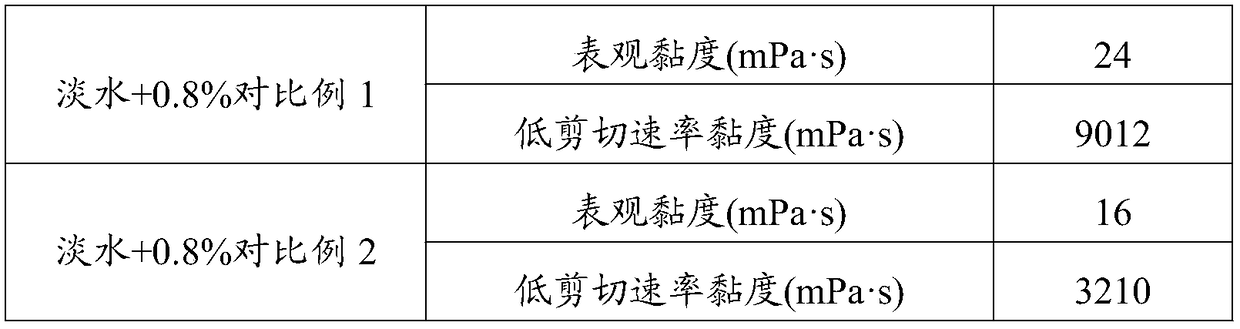

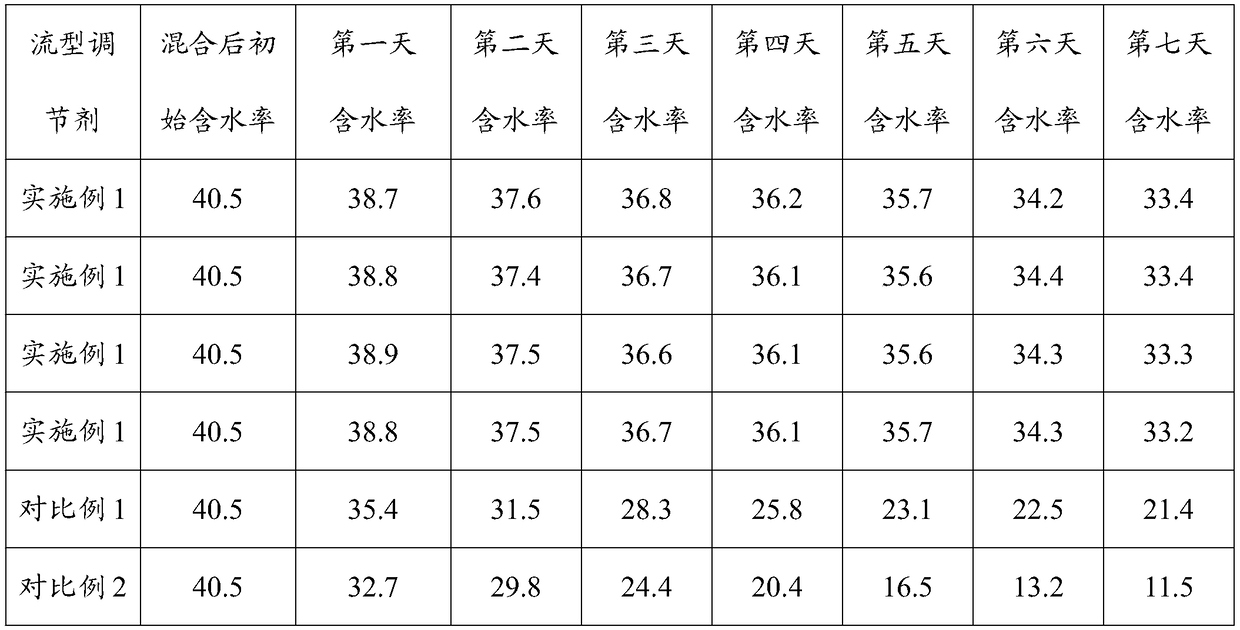

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the flow pattern regulator for drilling fluid according to the above technical scheme. In the present invention, the preparation method of the flow pattern regulator for drilling fluid includes the following steps:

[0040] Xanthan gum, wormwood gum, plantain gum, konjac gum, tamarind gum, hyaluronic acid and sodium alginate are mixed to obtain a flow pattern regulator for drilling fluid.

[0041] The present invention does not specifically limit the manner of mixing the above-mentioned raw materials, as long as the mixing manner known to those skilled in the art is adopted. In the specific embodiment of the present invention, the present invention specifically uses a kneader to uniformly mix the above-mentioned raw materials.

[0042] The present invention also provides the application of the flow pattern regulator for drilling fluid according to the above technical solution or the flow pattern regulator for drillin...

Embodiment 1

[0047] 40 parts by weight of xanthan gum, 10 parts by weight of sand wormwood gum, 20 parts by weight of psyllium gum, 10 parts by weight of tamarind gum, 5 parts by weight of konjac gum, 5 parts by weight of hyaluronic acid and 5 parts by weight of sodium alginate were compounded It is mixed evenly with a kneader to obtain a flow regulator.

Embodiment 2

[0049] Combine 50 parts by weight of xanthan gum, 20 parts by weight of sand wormwood gum, 10 parts by weight of psyllium gum, 15 parts by weight of tamarind gum, 10 parts by weight of konjac gum, 5 parts by weight of hyaluronic acid and 10 parts by weight of sodium alginate. It is mixed evenly with a kneader to obtain a flow regulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com