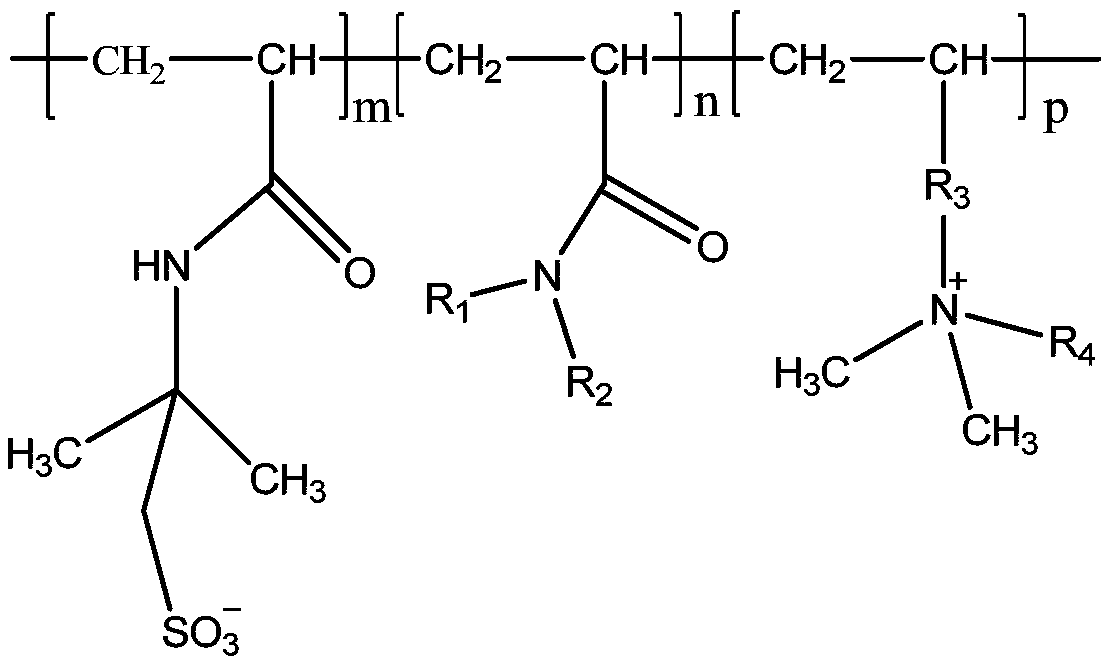

Anti-high temperature shearing agent for solid-free drilling fluid and preparation method thereof

A technology for drilling fluid and high temperature resistance, which is used in natural gas, coalbed methane drilling operations and oil fields, can solve problems such as poor temperature resistance, easy hydrolysis and temperature resistance, molecular chain breakage, etc. Promotion and application, the effect of increasing structural viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

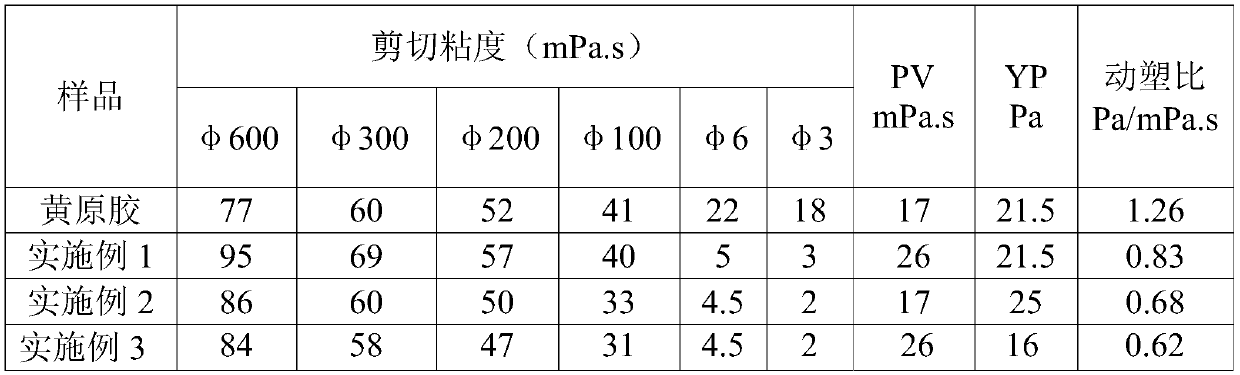

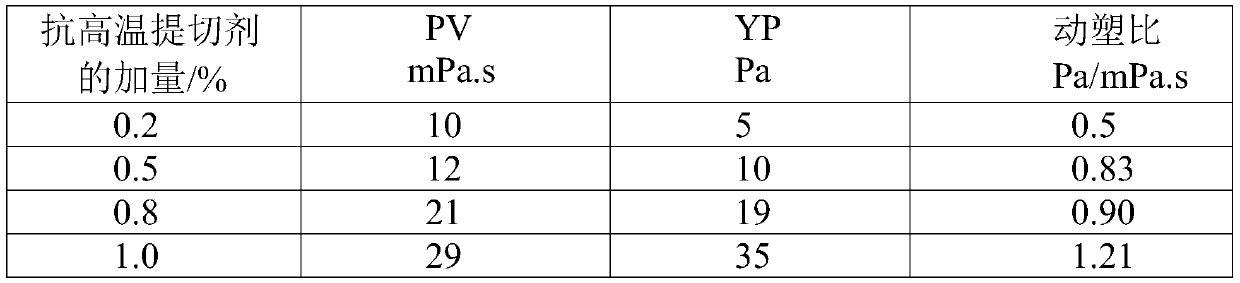

Embodiment 1

[0036] S1. Add 16g of 2-acryloyloxy-2-methylpropanesulfonic acid into a beaker, slowly add 65mL of solvent water, stir to dissolve 2-acryloyloxy-2-methylpropanesulfonic acid and place in an ice-water bath In, continue to stir constantly and slowly drop the NaOH solution of 5wt.% and carry out neutralization, obtain neutral solution (I);

[0037] S2. Add 28g of N,N-dimethylacrylamide, 7mL of 60wt.% dimethyl diallyl ammonium chloride solution and 2mL of 5wt.% EDTA solution to the neutral solution prepared in step S1, fully Stirring and dissolving obtains mixed solution (II);

[0038] S3. Add the mixed solution (II) prepared in step S2 into the reactor, add 0.05g ferrous ammonium sulfate and stir and pass nitrogen protection for 30min; then add 2.5mL 3wt.% sodium bisulfite solution, continue stirring and pass Nitrogen, obtain mixed solution (III);

[0039] S4, half of the mixed solution (III) prepared through step S3 is added in the constant pressure dropping funnel; the reacto...

Embodiment 2

[0042] S1. Add 20.5g sodium 2-acryloyloxy-2-methylpropanesulfonate into the beaker, slowly add 69mL of solvent water, stir to dissolve sodium 2-acryloyloxy-2-methylpropanesulfonate and place In an ice-water bath, continue to stir continuously and slowly add 1wt.% NaOH solution dropwise for neutralization to obtain a neutral solution (I);

[0043]S2, adding 24g of acrylamide to the neutral solution prepared in step S1, 5mL of 80wt.% methacryloxyethyltrimethylammonium chloride and 2mL of 5wt.% EDTA solution, fully stirred and dissolved to obtain a mixed solution ( II);

[0044] S3. Add the mixed solution (II) prepared in step S2 into the reactor, add 0.05g of ferrous ammonium sulfate and stir and pass nitrogen for 30min; then add 2mL of 3 wt.% sodium sulfite solution, continue to stir and pass nitrogen to obtain a mixture Solution (III);

[0045] S4, half of the mixed solution (III) prepared through step S3 is added in the constant pressure dropping funnel; the reactor is heat...

Embodiment 3

[0048] S1. Add 24g of sodium methacrylate into a beaker, slowly add 66mL of solvent water, stir to dissolve the 2-methylpropene sulfonate, put it in an ice-water bath, continue to stir and slowly add 5wt.% NaOH dropwise The solution is neutralized to obtain a neutral solution (I);

[0049] S2. Add 21g of methacrylamide to the neutral solution prepared in step S1, 4mL of acryloyloxyethyltrimethylammonium chloride with a concentration of 80% by mass and 2mL of 5wt.% EDTA solution, fully stir to dissolve A mixed solution (II) having a solution mass fraction of 35-40% is obtained;

[0050] S3. Add the mixed solution (II) prepared in step S2 into the reactor, add 0.05 g of ferrous ammonium sulfate, stir and pass nitrogen for 30 minutes; then add 2 mL of 3 wt.% sodium bisulfite solution, continue stirring and pass nitrogen , to obtain mixed solution (III);

[0051] S4, half of the mixed solution (III) prepared through step S3 is added in the constant pressure dropping funnel; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com