A 3D printable high-strength temperature-sensitive supramolecular hydrogel and its preparation method

A supramolecular hydrogel, 3D printing technology, applied in the direction of additive processing, can solve the problems of reducing the fidelity of the scaffold, easy to collapse, reducing the load cells, etc., and achieve the effect of favorable shape fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

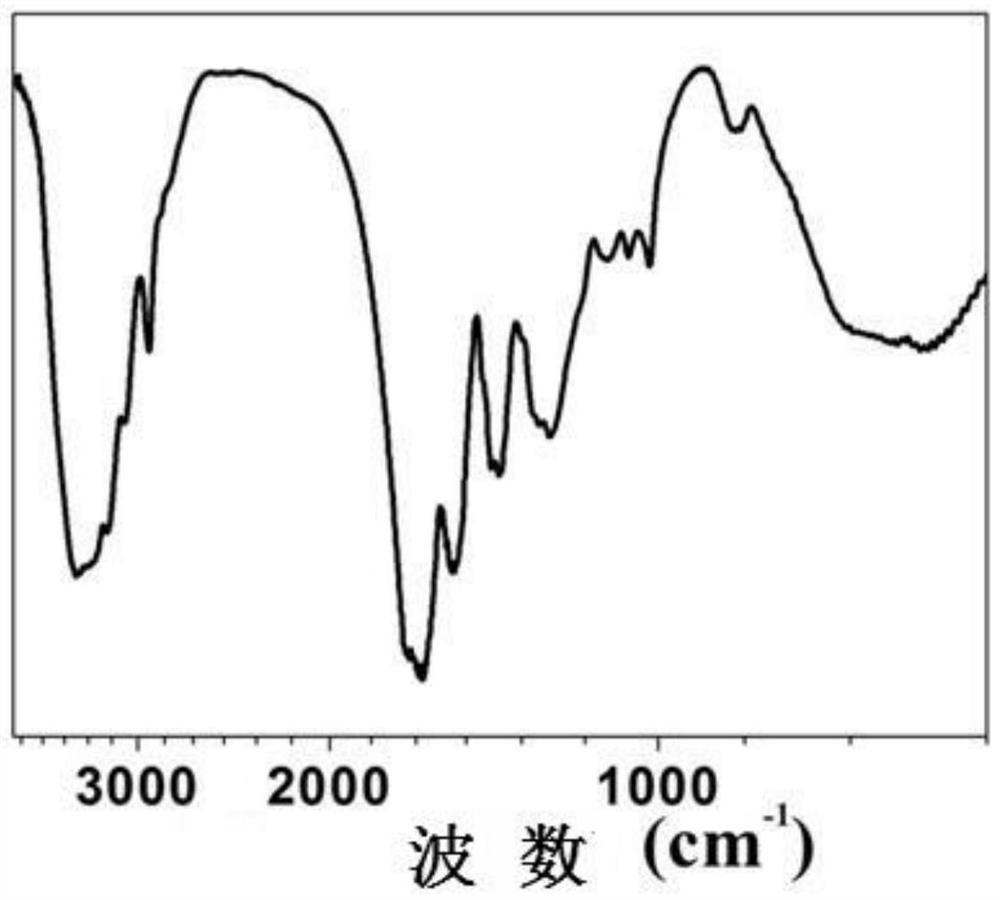

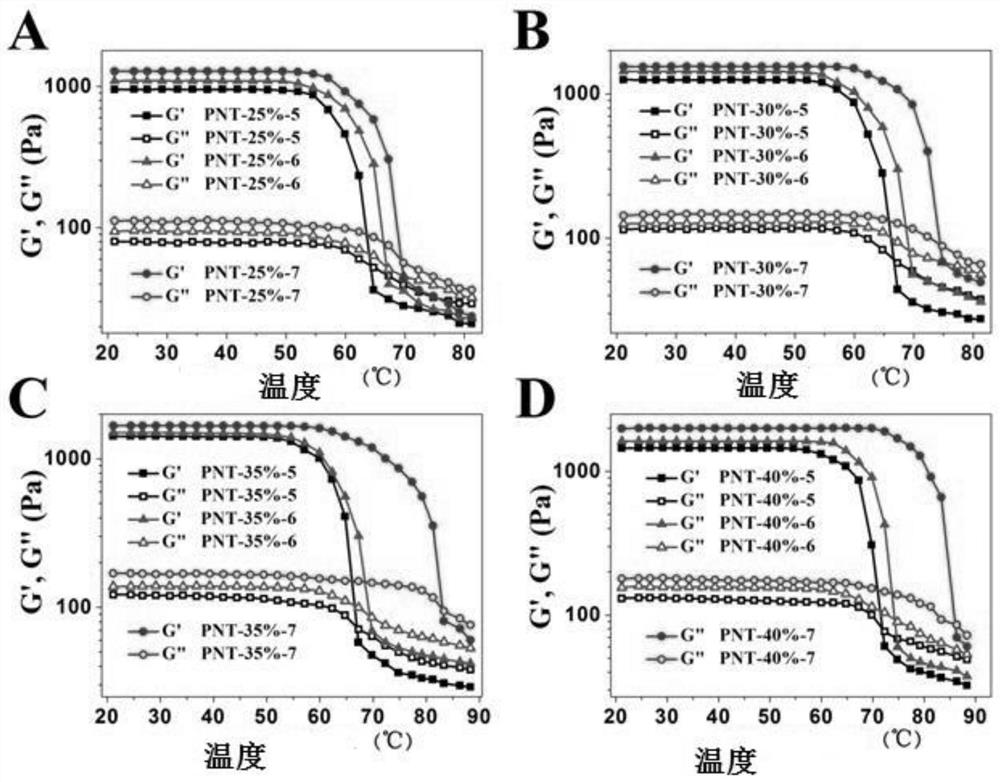

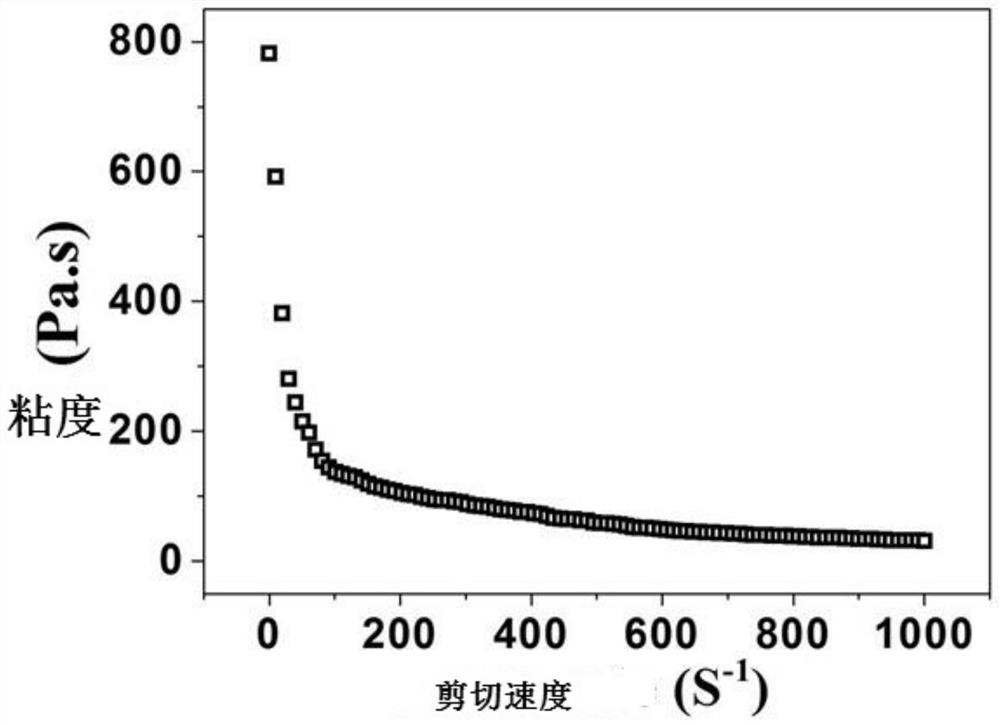

[0018] Synthesize copolymerized gels with different total monomer concentrations and different monomer mass ratios in the examples. The monomer concentration is 30%, and the mass ratio of acryloyl glycinamide and N-acryloyl (trimethylol) aminomethane is 5:1 as an example, where the monomer concentration refers to the sum of the mass of acryloyl glycinamide monomer and N-acryloyl (trimethylol) aminomethane monomer and the total mass of the two monomers and water ratio. Add 250 mg of acryloyl glycinamide monomer and 50 mg of N-acryloyl (trimethylol) aminomethane monomer into 1000 μL of deionized water, and add photoinitiator Irgacure 1173 (2-hydroxy-2 -methyl-1-phenyl-1-propanone) 9 μL. After the mixed solution is filled with nitrogen to remove oxygen, the mixed solution is injected into a closed mold, and the mold is irradiated in a UV curing box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com