A rock core oil washing instrument capable of automatic sampling and detection

A technology of oil washing instrument and core, which is applied in the field of core oil washing instrument for automatic sampling and detection, can solve problems such as troublesome detection and analysis, impact on human health, and leakage of organic solvent vapor, so as to reduce the number of sampling operations, prolong life, reduce The effect of small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

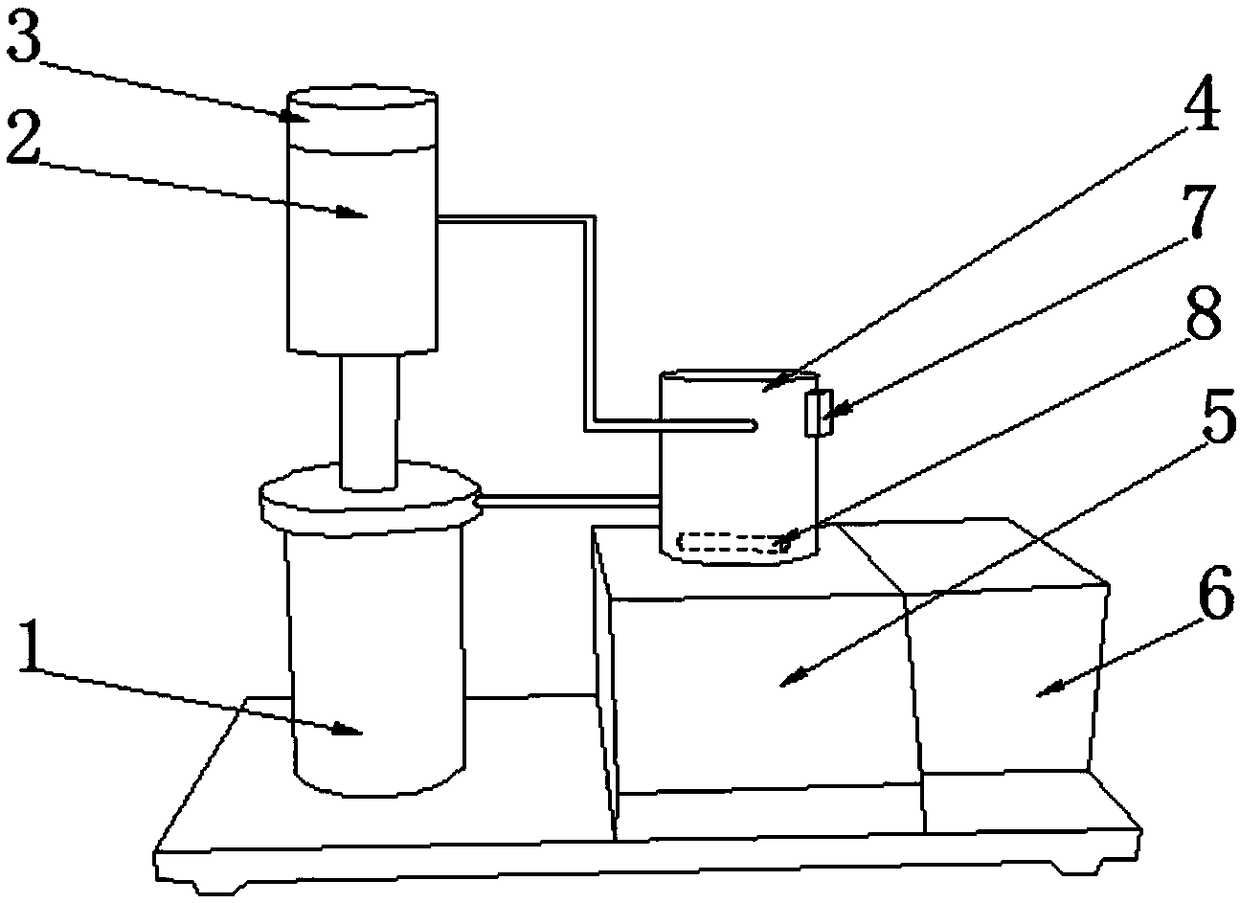

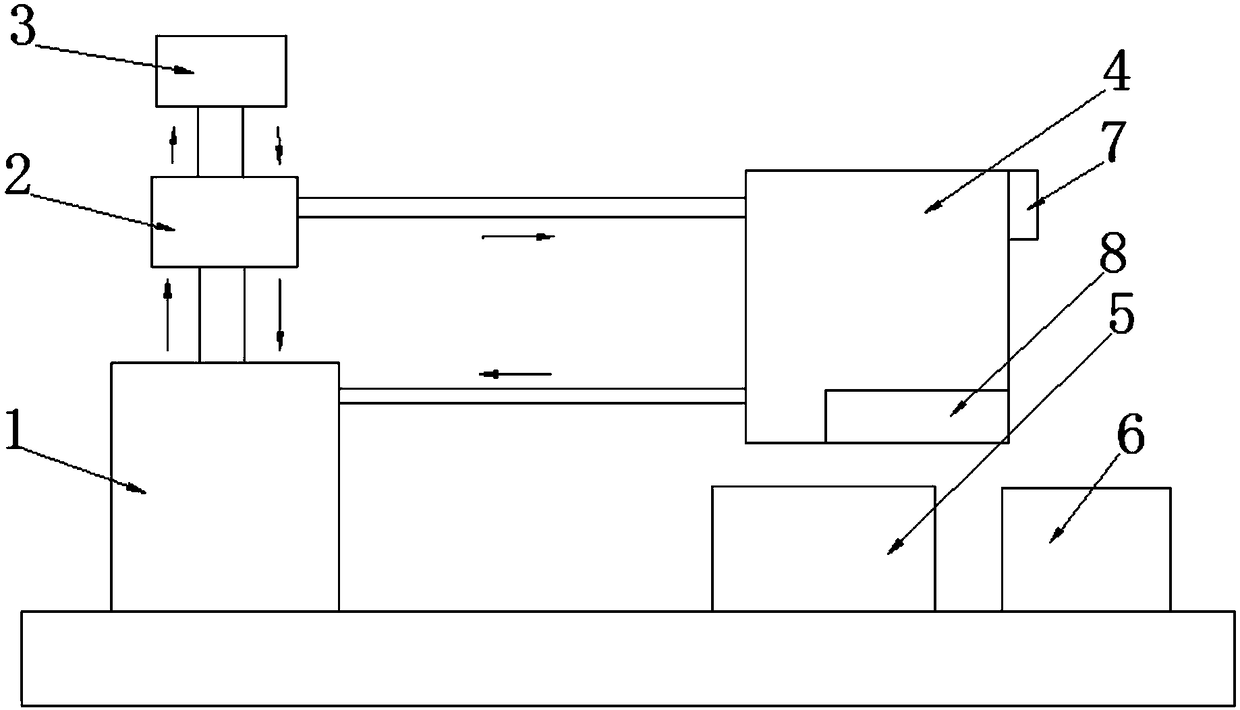

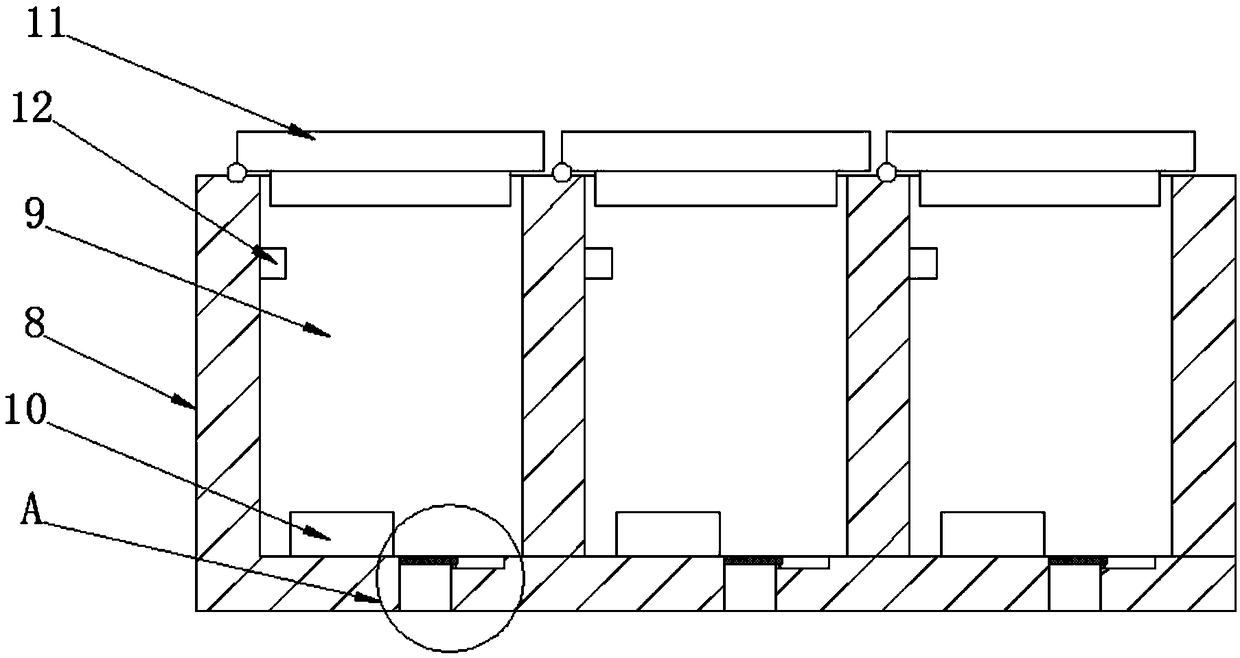

[0040] see Figure 1-2 , a kind of core oil washing instrument that can automatically sample and detect, comprising an oil washing instrument support, and the upper end of the oil washing instrument support is fixedly connected with a solvent chamber 1, an ultrasonic control system (the prior art) 5 and an electrical control system (the prior art) 6. Solvent chamber 1, ultrasonic control system 5 and electrical control system 6 are arranged in order from left to right. The organic solvent added in solvent chamber 1 is non-benzene or benzene homologues, and benzene or benzene homologues will affect the oil sensor in water. 10 causes interference, which affects the detection results. The surface of the solvent chamber 1 is alloyed with Cr, Si, and Al, so that the solvent chamber 1 quickly forms a dense oxide film during the heating and evaporation process, and firmly adheres to the ground. The surface of the solvent chamber 1, thereby effectively preventing the continuation of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com