Preparation method of touch display screen and bonding device

A technology of touch screen and bonding equipment, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve problems such as low production efficiency, improve production efficiency, reduce manufacturing costs, and save time effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

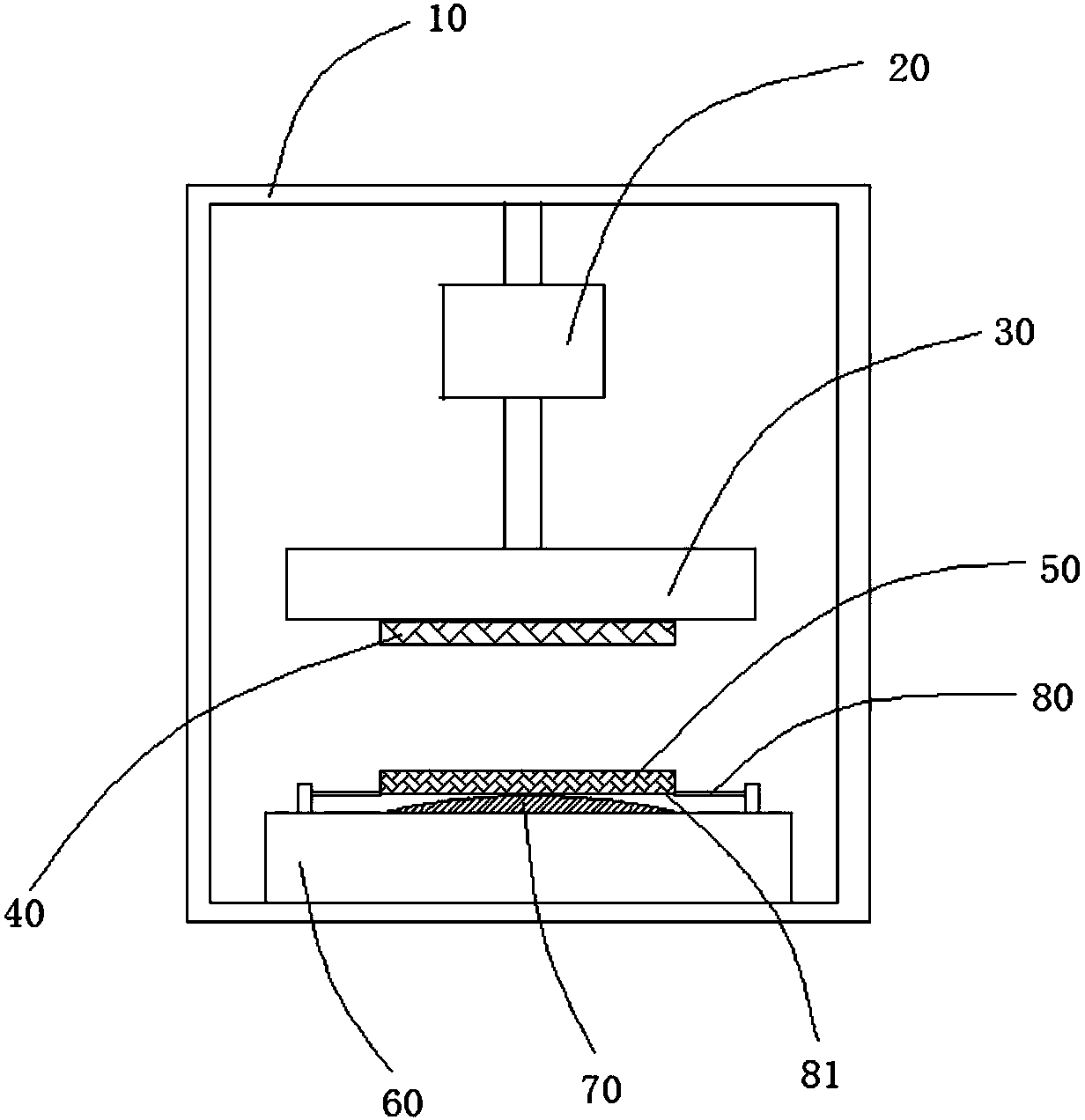

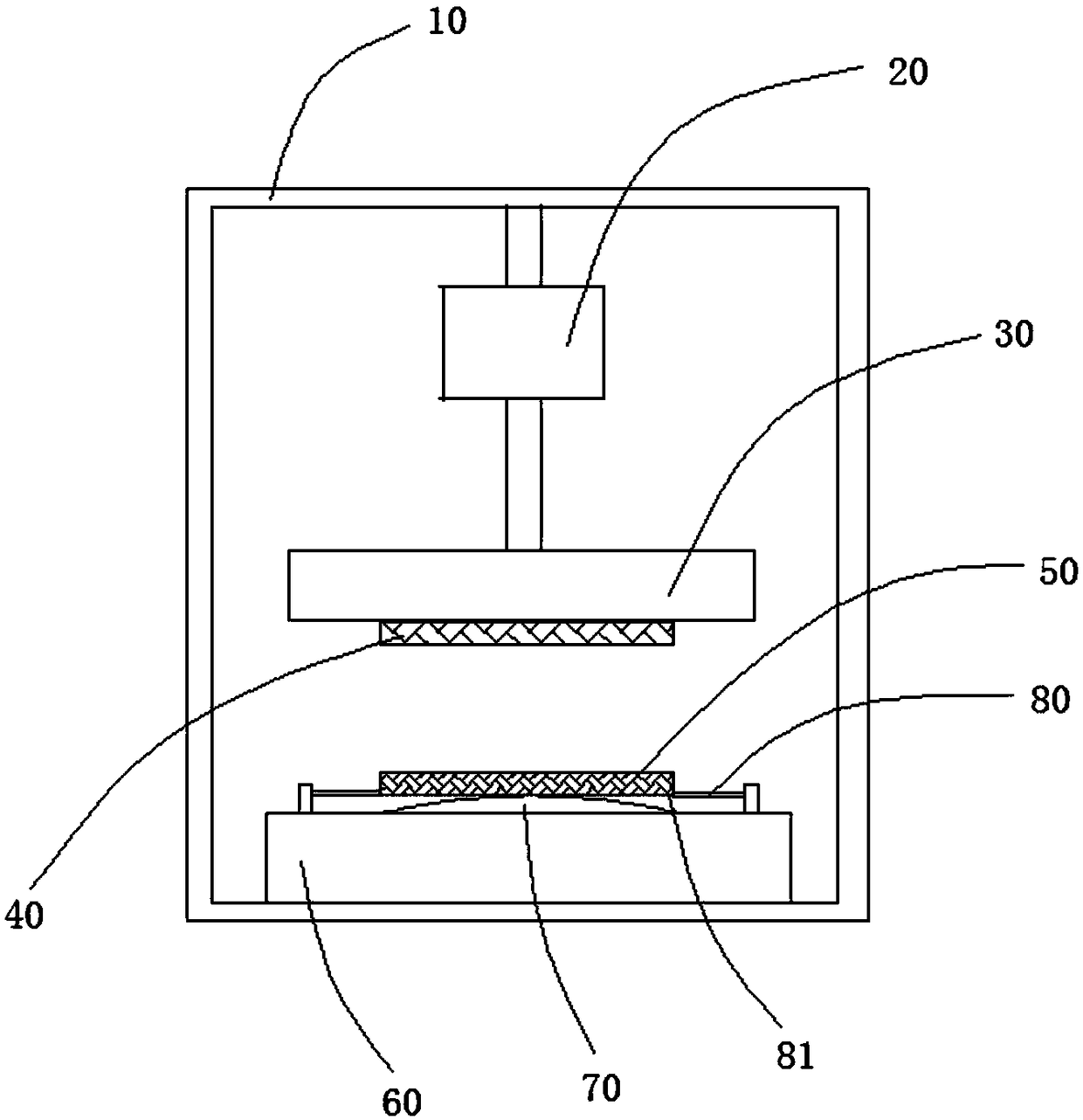

[0045]The preparation method of the touch screen provided by the present invention is to bond the touch screen and the TFT module in a non-vacuum state by extrusion, and the touch screen and the TFT module can be squeezed to Bubble discharge, this method can be realized in a non-vacuum state, and does not need to evacuate the equipment, thereby saving evacuation time and improving production efficiency.

[0046] In addition, the present invention innovatively adopts an extrusion method to bond the touch screen and the TFT module in a non-vacuum state, which is completely different from the traditional method of bonding using vacuum processing. Productivity provides new ideas.

[0047] The non-vacuum state referred to in the present invention refers to a normal pressure state. Atmospheric pressure is an atmospheric pressure, which is the gas pressure produced by the atmosphere in which we usually live. The non-vacuum state adopted in the present invention is relative to the t...

Embodiment 1

[0107] A method for preparing a touch screen, comprising the steps of:

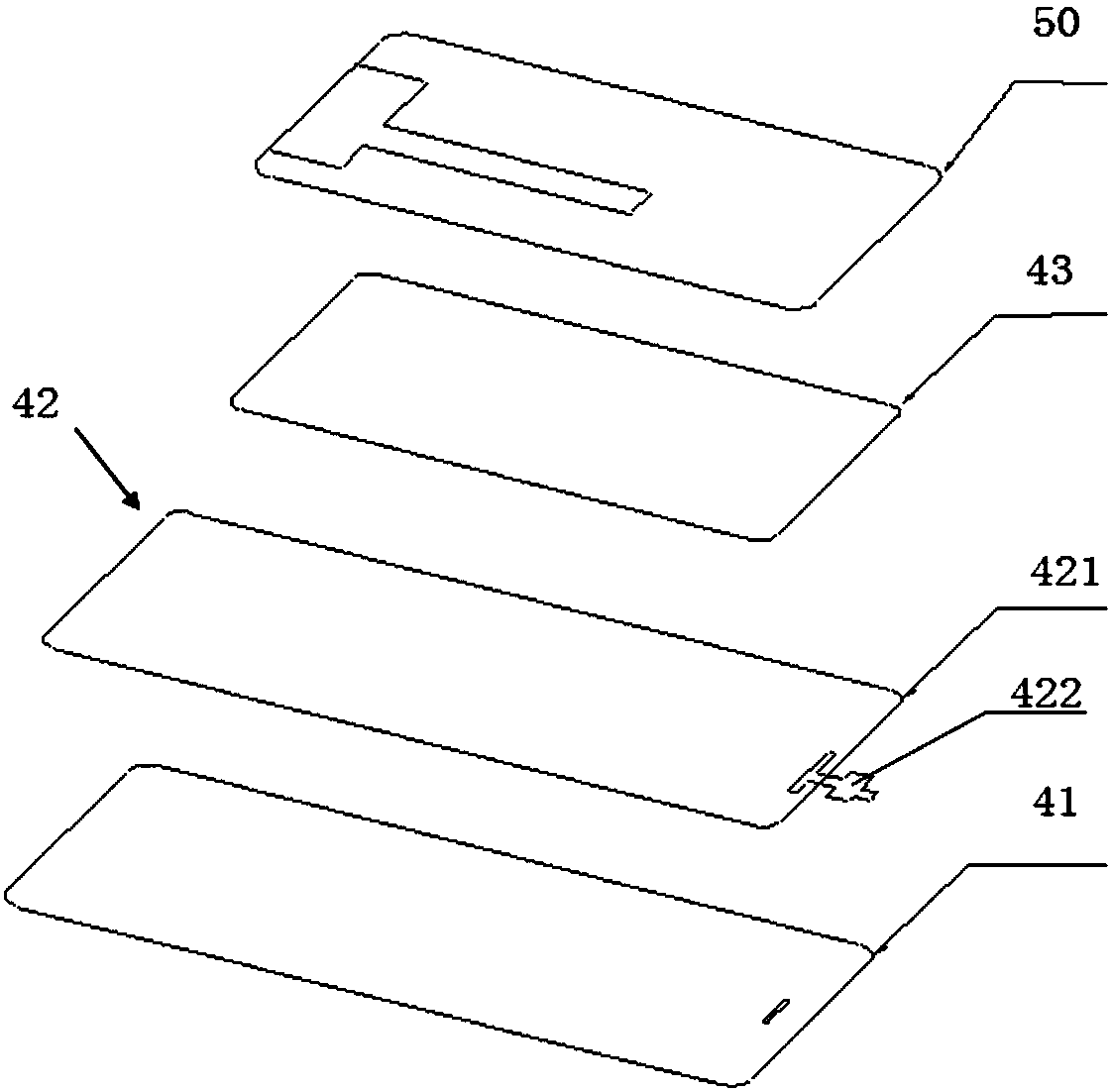

[0108] Step a): Obtain the film sensor 421 through processes such as photolithography, screen printing or laser;

[0109] Step b): Use hot pressing technology to assemble the thin film sensor 421 prepared in step a) and the flexible circuit board 422 into the FOG module 42; when hot pressing, the hot pressing pressure is 2MPa, the hot pressing temperature is 155°C and the hot pressing time is 9s;

[0110] Step c): The FOG module 42 prepared in step b) and the glass cover 41 are assembled into a touch screen 40 by using the L-shaped alignment bonding technology; when L-shaped alignment bonding is performed, the pressure is 0.4 MPa, and the bonding speed is 145 mm / s; the L-shaped alignment bonding technology in this process adopts the soft-to-hard bonding technology;

[0111] Step d): one side of the optical adhesive 43 is bonded to the FOG module 42 surface of the touch screen 40 prepared in step c) usi...

Embodiment 2

[0115] A method for preparing a touch screen, comprising the steps of:

[0116] Step a): Obtain the film sensor 421 through processes such as photolithography, screen printing or laser;

[0117] Step b): Assemble the thin film sensor 421 prepared in step a) and the flexible circuit board 422 into a FOG module 42 using hot pressing technology; when hot pressing, the hot pressing pressure is 2.3MPa, the hot pressing temperature is 160°C and the hot pressing time is 10s;

[0118] Step c): The FOG module 42 prepared in step b) and the glass cover 41 are assembled into a touch screen 40 by using the L-shaped alignment bonding technology; when L-shaped alignment bonding is performed, the pressure is 0.45 MPa, and the bonding speed is 150 mm / s; the L-shaped alignment bonding technology in this process adopts the soft-to-hard bonding technology;

[0119] Step d): Bond one side of the optical adhesive 43 with the FOG module 42 of the touch screen 40 prepared in step c) using the CCD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com