Vacuum pre-conditioner with automatic drainage device

A vacuum resurfacing and automatic drainage technology, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of increasing evacuation load and high energy consumption, and achieve the effect of reducing evacuation load, reducing condensed water, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

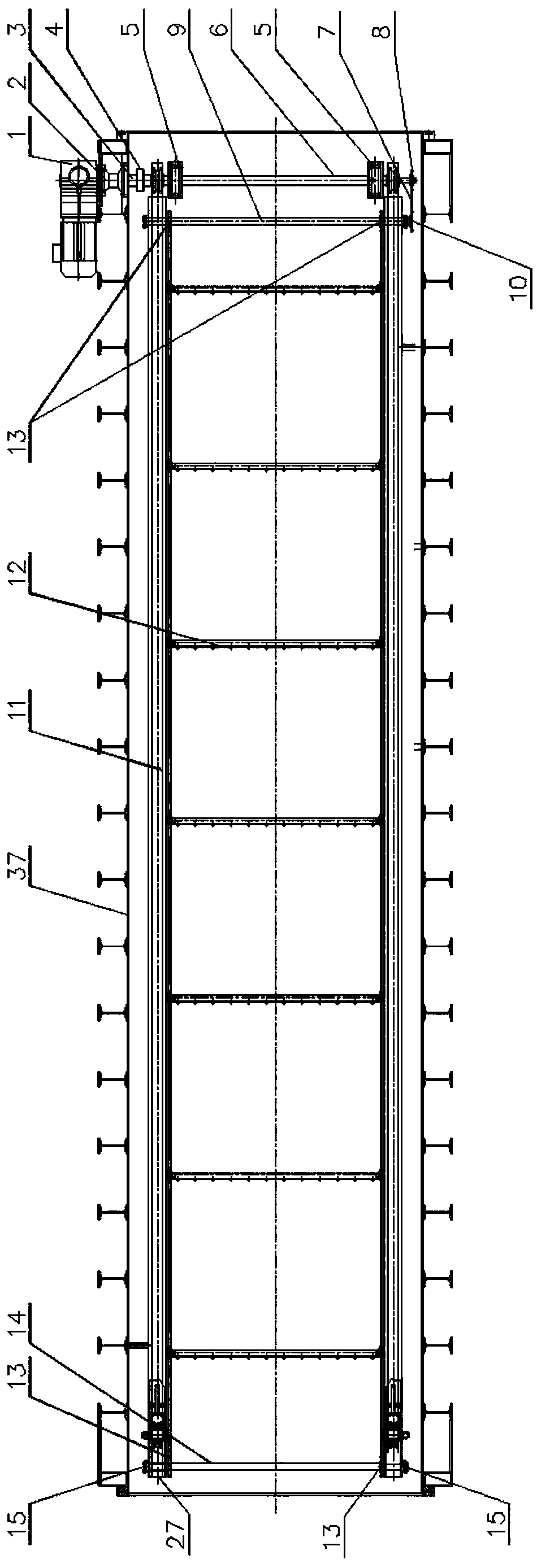

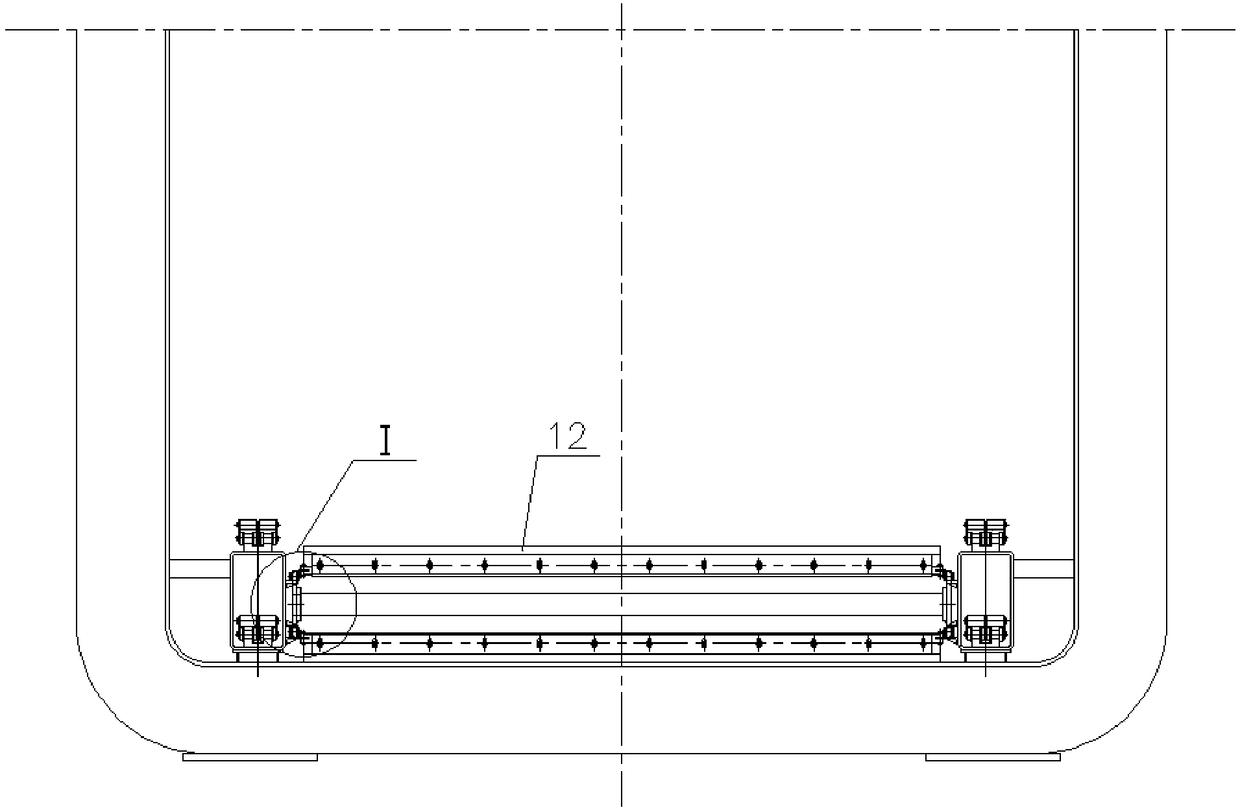

[0048] Embodiment one: see Figure 1-Figure 5 As shown, a vacuum dampening machine with an automatic drainage device includes a dampening machine casing 37, and the bottom of the dampening machine casing 37 is provided with an automatic drainage device. The bottom of the dampening machine casing 37 is rectangular. A scraper assembly for wiping water at the bottom of the cabinet and a power mechanism that drives the scraper assembly to move back and forth at the bottom of the humidifier cabinet.

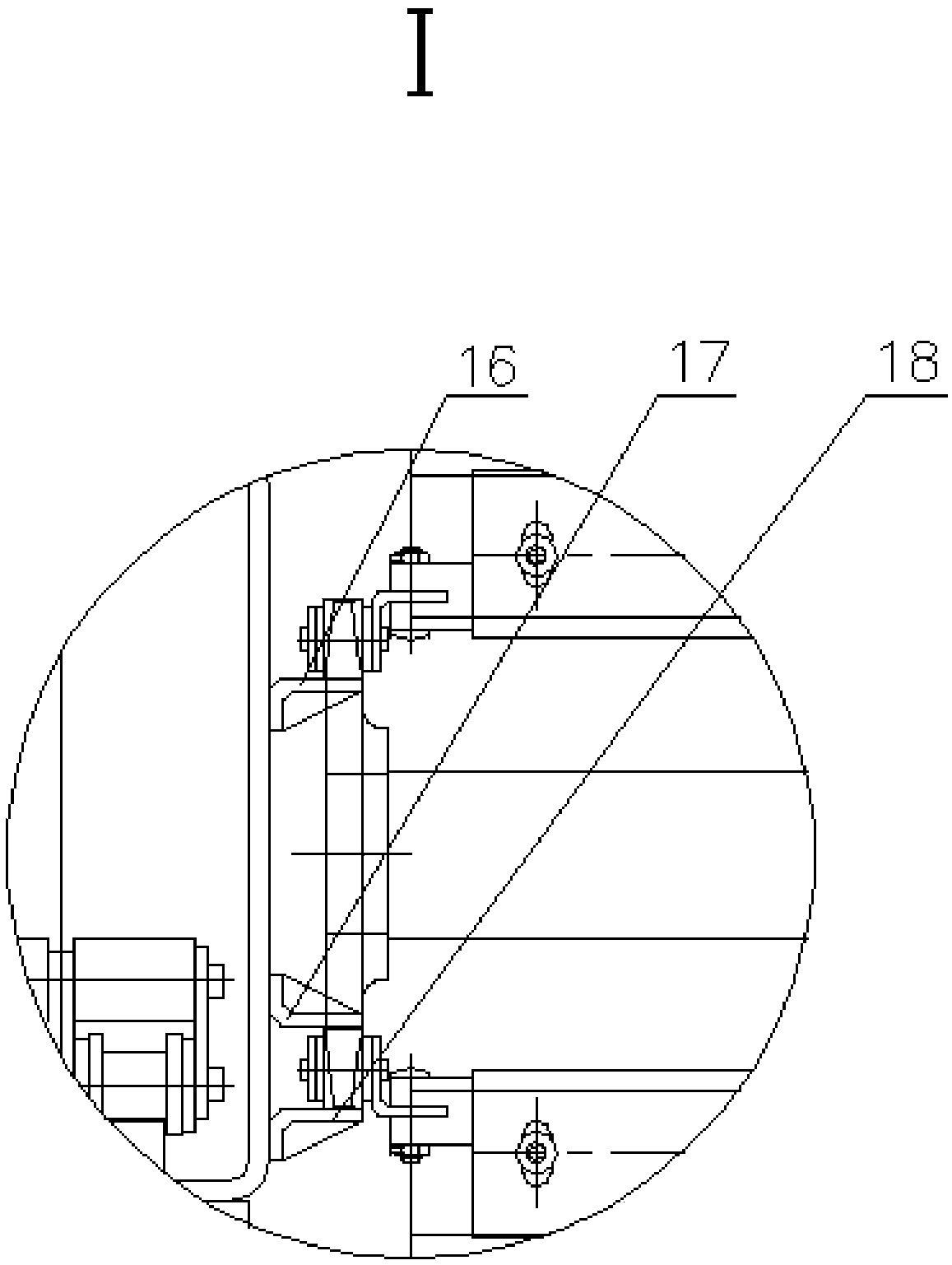

[0049] The power mechanism includes a driving shaft 9 and a driven shaft 14 respectively arranged at both ends of the humidifier casing 37, the driving shaft 9 is connected to a rotating drive device, and both ends of the driving shaft 9 and the driven shaft 14 are connected to scrapers Sprocket 13, the scraper sprocket 13 at both ends of the driving shaft 9 is connected to the scraper sprocket 13 at both ends of the driven shaft 14 through two scraper chains 11, each A scraper assem...

Embodiment 2

[0054] Embodiment two: if Figure 6 As shown, the rotary driving device includes a scraper chain drive motor 23, a power shaft 25, a drive sprocket 10 connected to the end of the drive shaft 9 and a drive chain 7, and the scraper chain drive motor 23 is arranged in the wet Outside the cabinet 37, the power shaft 25 passes through the outer wall of the humidifier cabinet 37, and one end of the power shaft 25 outside the humidifier cabinet 37 is connected with the scraper chain drive motor 23, and the power shaft 25 is in the One end in the humidifier casing 37 is connected with the power sprocket 2 26, and the transmission sprocket 10 and the power sprocket 2 26 are connected through the transmission chain 1 7. When the scraper chain drive motor 23 is turned on, the scraper assembly 12 will follow the The scraper chain translates and rotates to realize the function of wiping water on the bottom of the humidifier cabinet 37, thereby pushing the condensed water at the bottom of t...

Embodiment 3

[0059] Embodiment three: see Figure 11-Figure 16 , a vacuum conditioner with automatic drainage device, comprising a conditioner casing 37, the bottom of the conditioner casing 37 is provided with an automatic drainage device, and the automatic drainage device includes a scraper assembly for scraping water at the bottom of the conditioner casing 37 And the power mechanism that drives the scraper assembly to move back and forth at the bottom of the humidifier casing 37 .

[0060] The power mechanism includes a sliding shaft 40, a lead screw 46, a lead screw nut 47, a lead screw driving device and a scraper drag shaft 52, and one lead screw 46 is respectively arranged at the front and rear sections of the bottom of the humidifier box. , the screw driving device is arranged at the bottom of the humidifier box, the screw driving device drives the screw to rotate, the screw nut 47 is screwed on the screw 46, and the scraper drags The shaft 52 is fixedly connected to the lead scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com