Compound-extruded-rice glutinous-rice cakes and preparation method thereof

A technology of glutinous rice cakes and extrusion puffing, which is applied in the field of compound extruded rice glutinous rice cakes and its preparation, can solve the problems of glutinous rice cakes that are difficult to mash, and achieve the effects of easy mashing, ripening, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

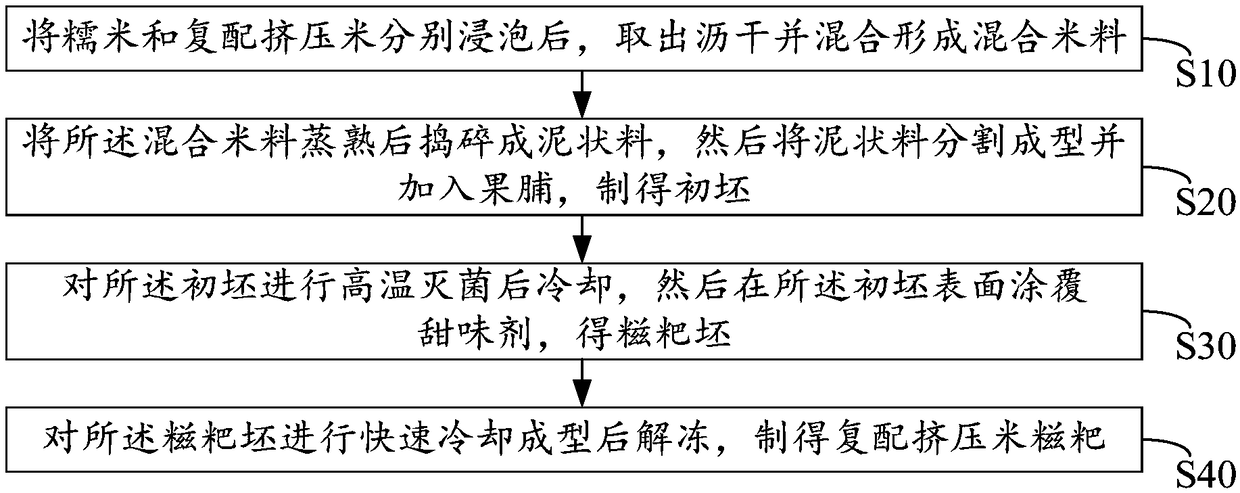

[0034] The present invention also proposes a preparation method of compound extruded rice glutinous rice cake, figure 1 It is an embodiment of the preparation method of compound extruded rice glutinous rice cake provided by the present invention. see figure 1 , in the present embodiment, the preparation method of the compound extruded rice glutinous rice cake comprises the following steps:

[0035] Step S10, after soaking the glutinous rice and the compound extruded rice respectively, take out, drain and mix to form a mixed rice material;

[0036] Soak the glutinous rice and the compound extruded rice separately, wherein, the soaking time of the glutinous rice is 50-70 minutes, and the soaking time of the compound extruded rice is 4-6 minutes, and the soaking time of the glutinous rice is 4-6 minutes, and the soaking time can be soaked under the water temperature condition, soaking The amount of water to be added is based on the complete submersion of the rice grains (you ca...

Embodiment 1

[0048] (1) Weigh 250g of glutinous rice flour and 750g of corn flour, put them into a twin-screw extrusion extruder and extrude them to obtain extruded rice for subsequent use; wherein, the parameters of the extrusion extruder are set to: solid feed The feed rate is 7kg / h, the liquid feed rate is 1.5kg / h, the screw speed is 60rpm, and the temperature settings of the five temperature zones are 60°C, 80°C, 120°C, 120°C and 70°C.

[0049] (2) Weigh 600g of glutinous rice and soak in water for 60min, weigh 400g of compound extruded rice and soak in water for 5min, then remove the soaked rice grains from the water, drain and mix evenly to form a mixed rice material, which is set aside.

[0050] (3) Steam the mixed rice material on a steamer for 35 minutes, then mash it for 5 minutes to form a mud-like material, then divide the mud-like material into shape, and add 100 g of hawthorn strips in the process of dividing and forming to obtain a blank ;

[0051] (4) Put the blank into a ...

Embodiment 2

[0054] (1) Weigh 300g of glutinous rice flour and 700g of corn flour, put them into a twin-screw extrusion extruder and extrude them to obtain extruded rice for subsequent use; wherein, the parameters of the extrusion extruder are set to: solid feed The feed rate is 8kg / h, the liquid feed rate is 2.5kg / h, the screw speed is 40rpm, and the temperature settings of the five temperature zones are 40°C, 60°C, 100°C, 100°C and 60°C.

[0055] (2) Weigh 500g of glutinous rice and soak in water for 50min, weigh 500g of compound extruded rice and soak in water for 4min, then remove the soaked rice grains from the water, drain and mix evenly to form a mixed rice material for later use.

[0056] (3) Steam the mixed rice material on a steamer for 40 minutes, then mash it for 4 minutes to form a mud-like material, then divide the mud-like material into shape, and add 50 g of hawthorn strips in the process of dividing and forming to obtain a blank ;

[0057] (4) Put the preform into a dry s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com