Rotary type ladle baker

A baker and rotary technology, applied in the direction of casting melt container, metal processing equipment, casting equipment, etc., can solve the problems of high gas consumption, low baking efficiency, long heating time, etc., and achieve simple production process, Enhanced baking effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

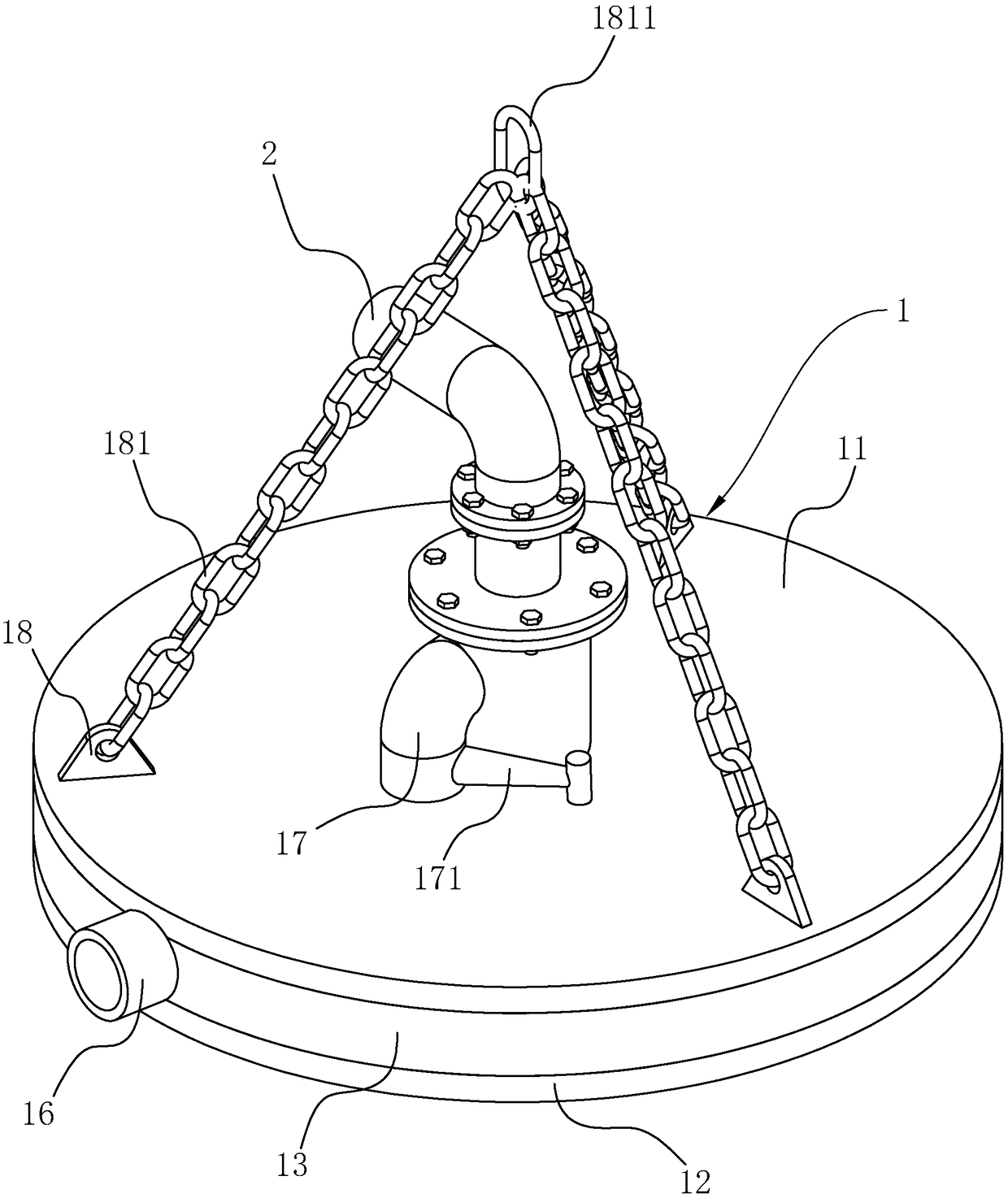

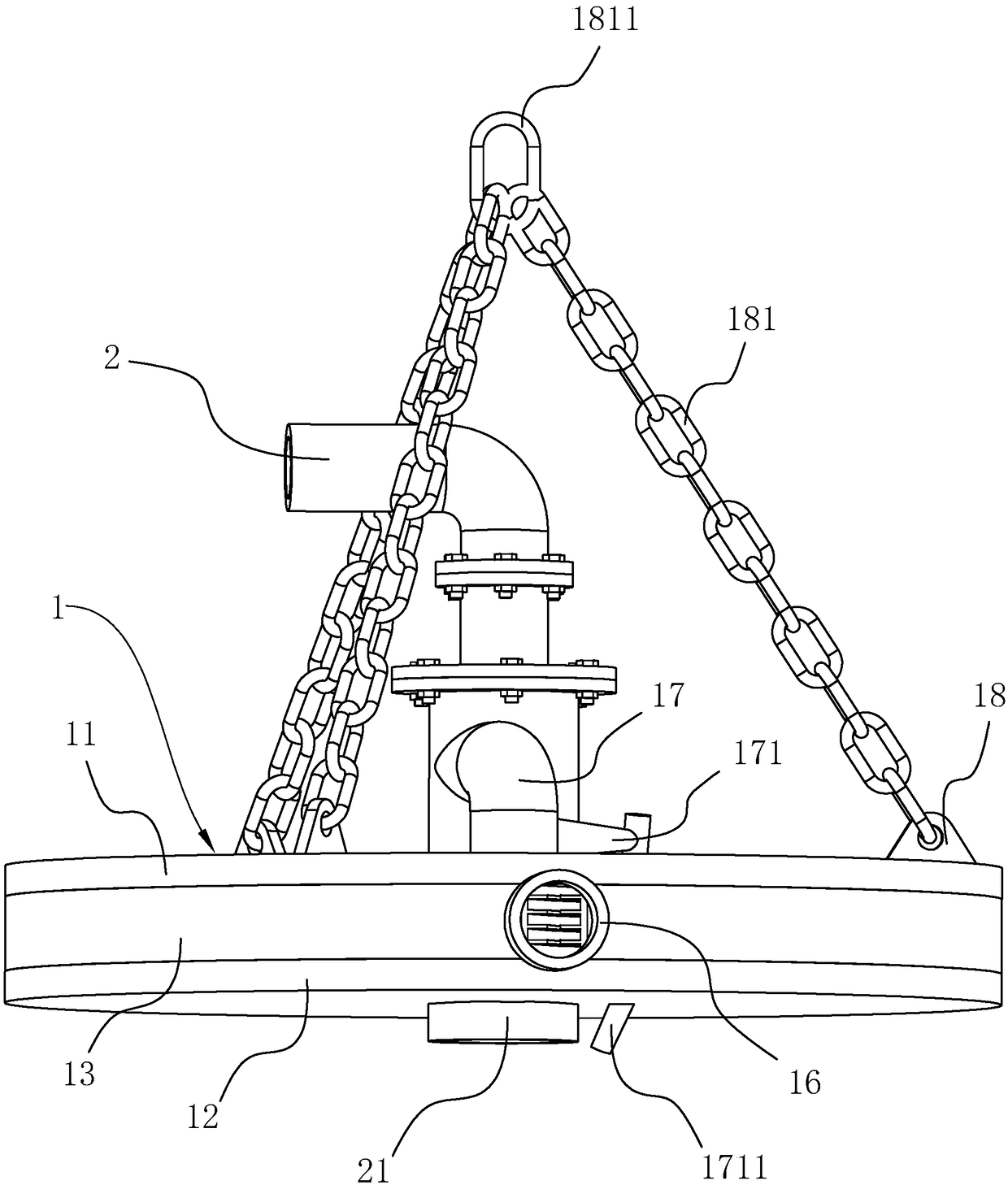

[0045] Embodiment: a kind of revolving baker, such as figure 1 and figure 2 As shown, it includes a cover 1, a gas pipe 2 is fixedly connected in the middle of the cover 1, the gas pipe 2 is set through the cover 1, the gas tube 2 is set through the cover 1, and the gas tube 2 is fixedly connected at one end of the cover 1 A burner 21 is arranged, and the burner 21 is arranged perpendicular to the lower surface of the cover 1 . The staff passes the gas into the burner 21 through the gas pipe 2, and the burner 21 ignites the gas, and the flame is sprayed from the burner 21 to the bottom of the cover 1. When the cover 1 is covered on the ladle 3, the burner 21 sprays The flame that goes out roasts ladle 3.

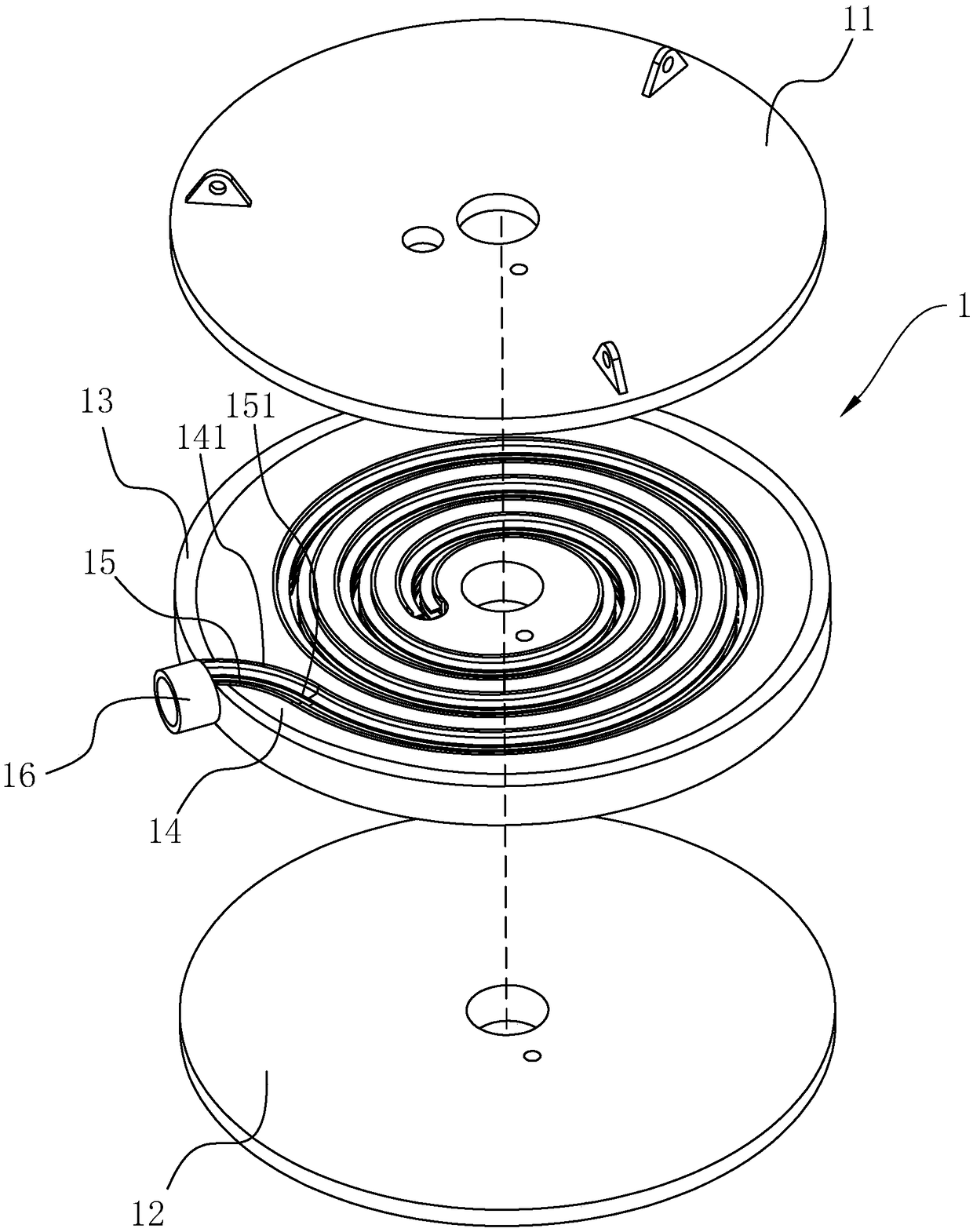

[0046] Such as image 3 and Figure 4 As shown, the cover 1 includes a circular lower plate 12 with an upper surface, and an annular outer wall 13 is fixedly connected above the lower plate 12. The outer wall 13 is arranged along the peripheral line of the lower plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com