A combined intelligent self-powered vibration-damping boring bar

A self-powered, combined technology, applied in boring bars, metal processing equipment, metal processing, etc., can solve the problems of complex structure, automatic adjustment of stiffness and damping of passive vibration absorbers, poor pertinence, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

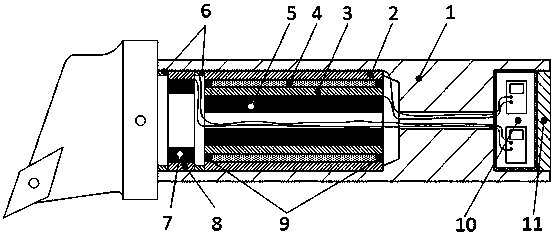

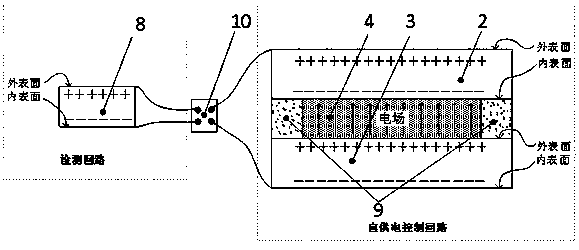

[0019] Such as figure 1 As shown, a combined intelligent self-powered vibration-damping boring bar according to the present invention includes a boring bar 1, a first piezoelectric ceramic sheet 2, a second piezoelectric ceramic sheet 3, an electrorheological fluid 4, and a large mass block 5 , a positioning gear ring 6, a small mass block 7, a third piezoelectric ceramic shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com