Injection molding method of bimodal polyethylene product

A bimodal polyethylene injection molding technology, which is applied in the field of injection molding of high-strength branched bimodal polyethylene products, can solve the problems of insufficient mechanical properties of bimodal polyethylene products, and achieve the effect of promoting formation and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

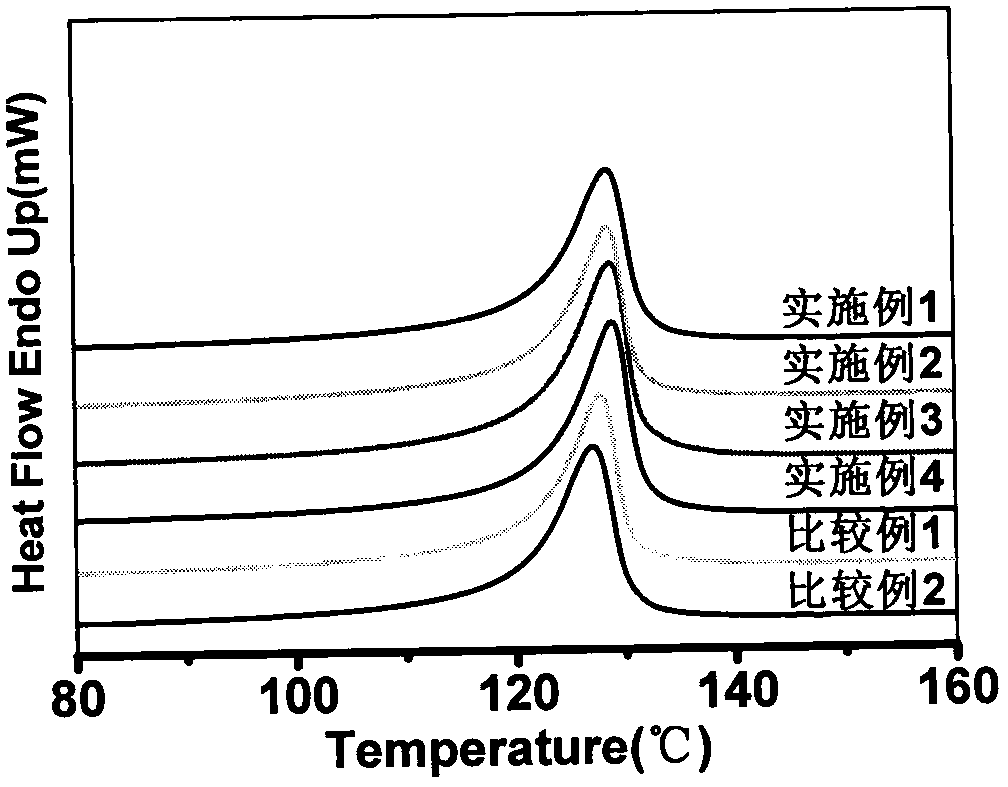

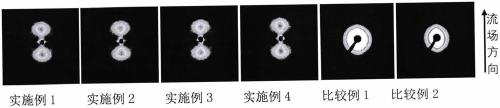

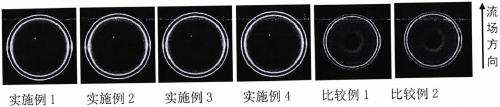

Embodiment 1

[0032] Add 1000g of bimodal polyethylene with a weight average molecular weight of 210000 and a molecular weight distribution of 24, 1250mg of antioxidant 1010, and 1000mg of lubricant into a screw injection molding machine for injection molding to obtain bimodal polyethylene products, wherein the high molecular weight part of bimodal polyethylene The mass content is 10%, the weight average molecular weight is 820,000, the molecular weight distribution is 3, and the high molecular weight part contains 60 ethyl branched chains per 10,000 carbon atoms; the mass content of the bimodal polyethylene low molecular weight part is 90%, and the weight average molecular weight 170000, the molecular weight distribution is 4; the material is melted at 150°C during the injection molding stage, the temperature through the nozzle is 150°C, the injection pressure is 350MPa, the holding pressure is 240MPa, the holding time is 10s, the mold temperature is 30°C, and the cooling rate 30°C / min.

Embodiment 2

[0034] Add 1,000g of bimodal polyethylene with a weight average molecular weight of 350,000 and a molecular weight distribution of 35, 800mg of antioxidant 1076, and 600mg of a flame retardant into a screw injection molding machine for injection molding to obtain bimodal polyethylene products, wherein the bimodal polyethylene has a high molecular weight The mass content of the part is 30%, the weight average molecular weight is 1,000,000, and the molecular weight distribution is 5. The high molecular weight part contains 30 butyl branches per 10,000 carbon atoms; the mass content of the low molecular weight part of bimodal polyethylene is 70%, and the weight average The molecular weight is 60000, the molecular weight distribution is 5; the material is melted at 178°C during the injection molding stage, the temperature passing through the nozzle is 183°C, the injection pressure is 300MPa, the holding pressure is 200MPa, the holding time is 20s, the mold temperature is 20°C, the c...

Embodiment 3

[0036] Add 1,000 g of bimodal polyethylene with a weight average molecular weight of 500,000 and a molecular weight distribution of 47 and 900 mg of antioxidant 168 into a screw injection molding machine for injection molding to obtain bimodal polyethylene products, wherein the high molecular weight part of bimodal polyethylene has a mass content of 42 %, the weight-average molecular weight is 1,200,000, and the molecular weight distribution is 7. The high molecular weight part contains 20 hexyl branched chains per 10,000 carbon atoms; In the injection molding stage, the material is melted at 190°C, the temperature through the nozzle is 198°C, the injection pressure is 200MPa, the holding pressure is 100MPa, the holding time is 30s, the mold temperature is 30°C, and the cooling rate is 50°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com