High-speed rubber track and high-speed rubber track pattern side rubber

A technology of rubber crawler and side rubber, which is applied in the field of high-speed rubber crawler and high-speed rubber crawler pattern side rubber, can solve the problems of large effect, low efficiency, slow speed, etc., achieve fast and stable walking, and enhance tensile strength. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of high-speed rubber track of the present invention is as follows:

[0035] 1. Preparation of wheel side rubber 2

[0036] The material formula and the manufacturing method of wheel side rubber 2 can be identical with driving tooth 5.

[0037] 2. Preparation of guide teeth 4

[0038] 2.1. Plasticizing the main rubber material of the guide gear 4: put NR RSS3, SBR 1502, and BR900 into the internal mixer for plasticizing, and discharge the glue at 165°C in the actual measurement. parked for more than 8 hours;

[0039] 2.2. Carry out the first stage of mixing of the guide gear 4: put the rubber main material masticated in 2.1 into the internal mixer, and masticate again, the masticating time is 40-60 seconds, and the speed is 40-50 rpm After the mastication is completed, add zinc oxide, stearic acid, dispersant FS210, anti-aging agent RD, anti-aging agent 4010, C5 resin and carbon fiber, and at the same time, add carbon black N220 and white carbon...

Embodiment 1

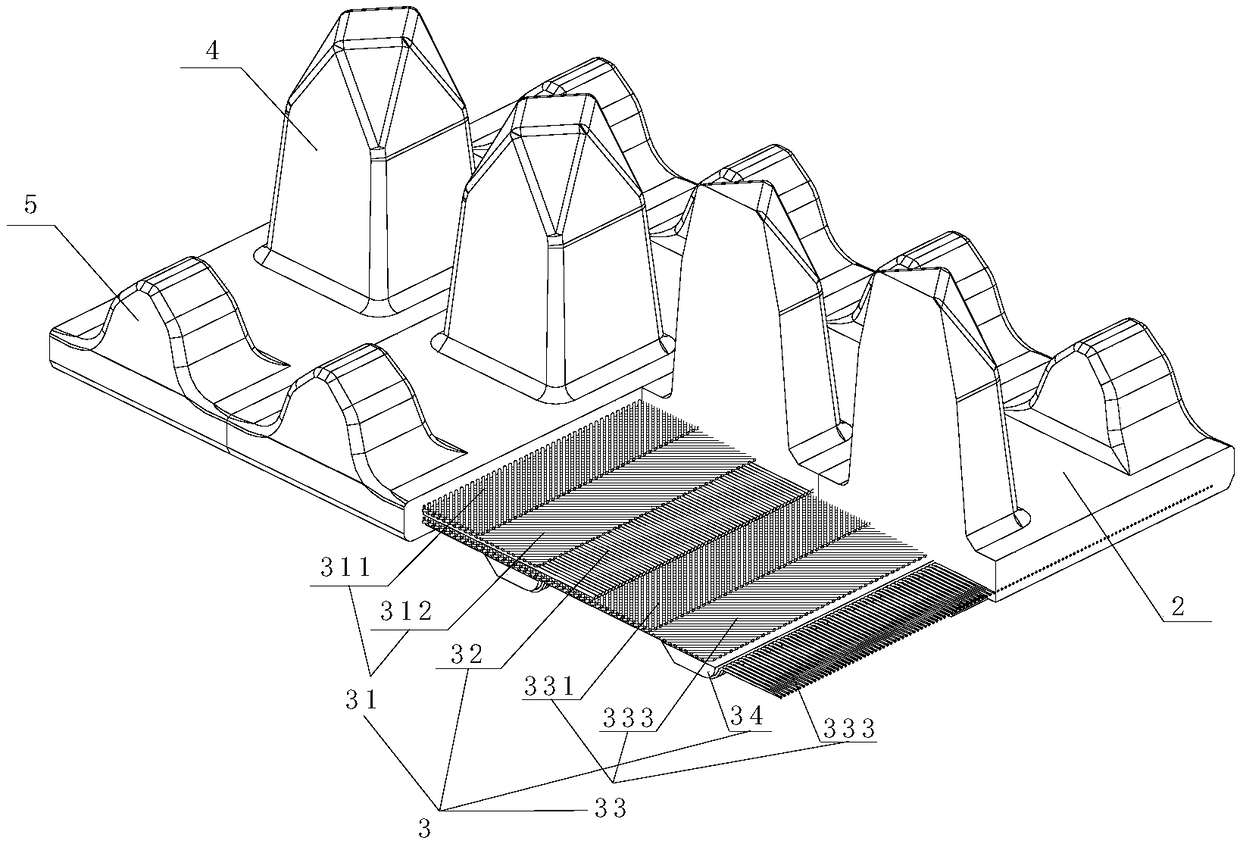

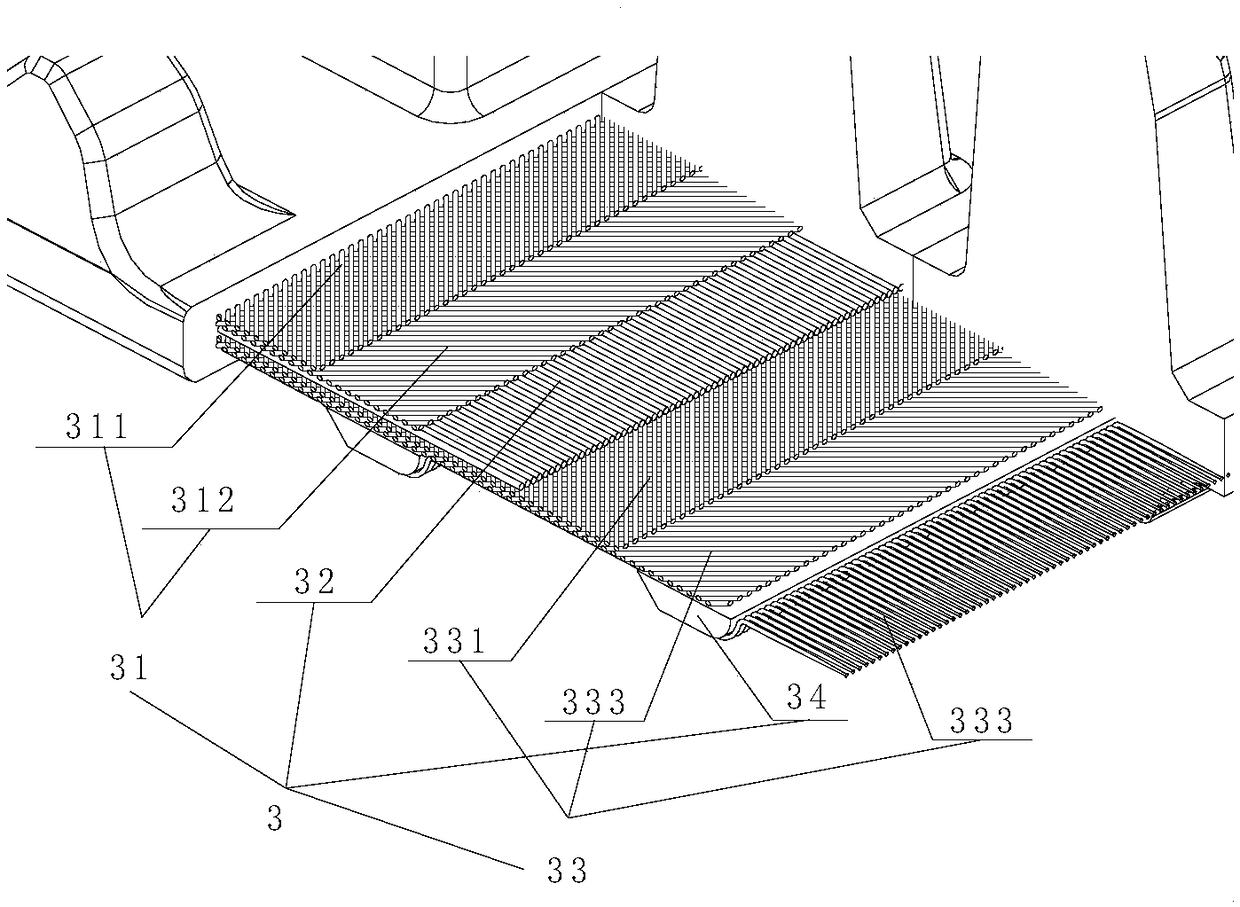

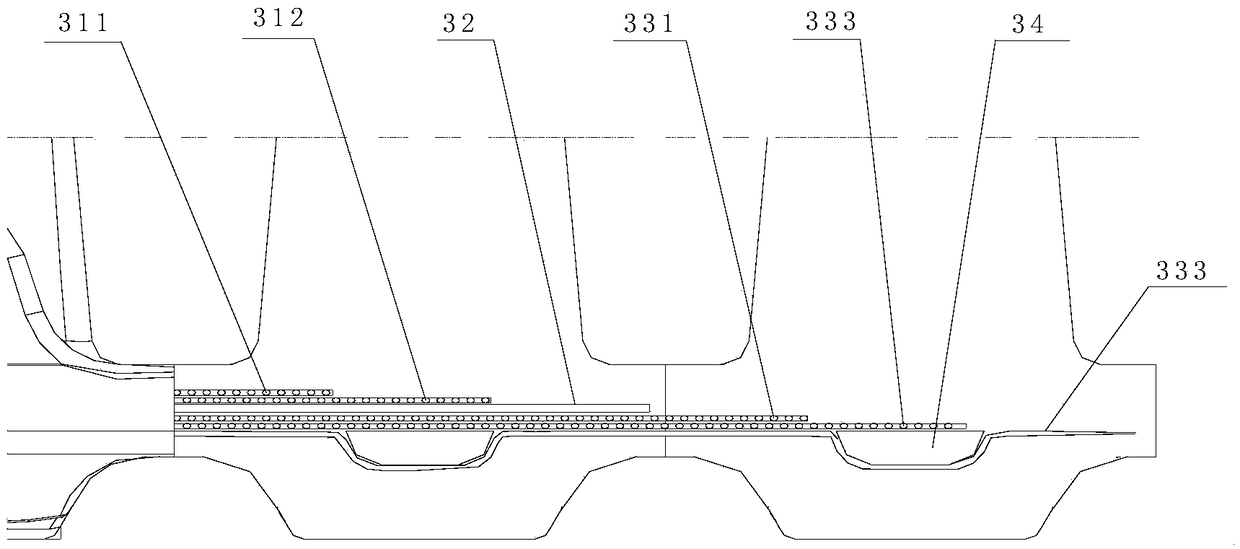

[0059] In this embodiment, the first composite support layer 31 is sequentially the first inclined support layer 311 and the second inclined support layer 312 from the inside to the outside, and the laying direction of the first inclined support layer 311 is in line with the track The included angle in the width direction is 45 degrees, and the second inclined support layer 312 is laid at an angle of 90 degrees relative to the first inclined support layer 311; the second composite support layer 33 is in order from inside to outside: The third inclined supporting layer 331, the fourth inclined supporting layer 332 and the flat supporting layer 333, the laying direction of the third inclined supporting layer 331 is the same as that of the first inclined supporting layer 311, the fourth inclined supporting layer 331 The laying direction of the supporting layer 332 is the same as that of the second inclined supporting layer 312, and the laying of the flat supporting layer 333 is pa...

Embodiment 2

[0068] The difference from Embodiment 1 is that the angle between the laying direction of the first inclined support layer 311 and the track width direction is 30 degrees, and the second inclined support layer 312 is opposite to the first inclined support layer. 311 is laid at an angle of 120 degrees; the supporting material selected is polyester fiber cloth.

[0069] The small vertical grooves 111 are inclined at an angle of 8 degrees relative to the circumferential direction of the track.

[0070] The length of the support core 34 is 20mm shorter than the width of the rubber track.

[0071] The height of the guide teeth 4 is 100mm.

[0072] The material formula of the guide tooth 4 is calculated by weight: 85 parts of NR RSS3, 15 parts of SBR 1502, 15 parts of BR9000, 78 parts of carbon black N220, 13 parts of white carbon black, 4.5 parts of zinc oxide, 2 parts of stearic acid, 3 parts of dispersant FS210, 2.5 parts of anti-aging agent RD, 2 parts of anti-aging agent 4010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com