Sedimentation air floatation composite tank

A sedimentation air flotation and sedimentation tank technology, which is applied in the direction of sedimentation treatment, flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, etc., can solve the problem of large area occupied by sedimentation tanks and air flotation tanks, and achieve improved sewage treatment Effect, the effect of enhancing the air floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

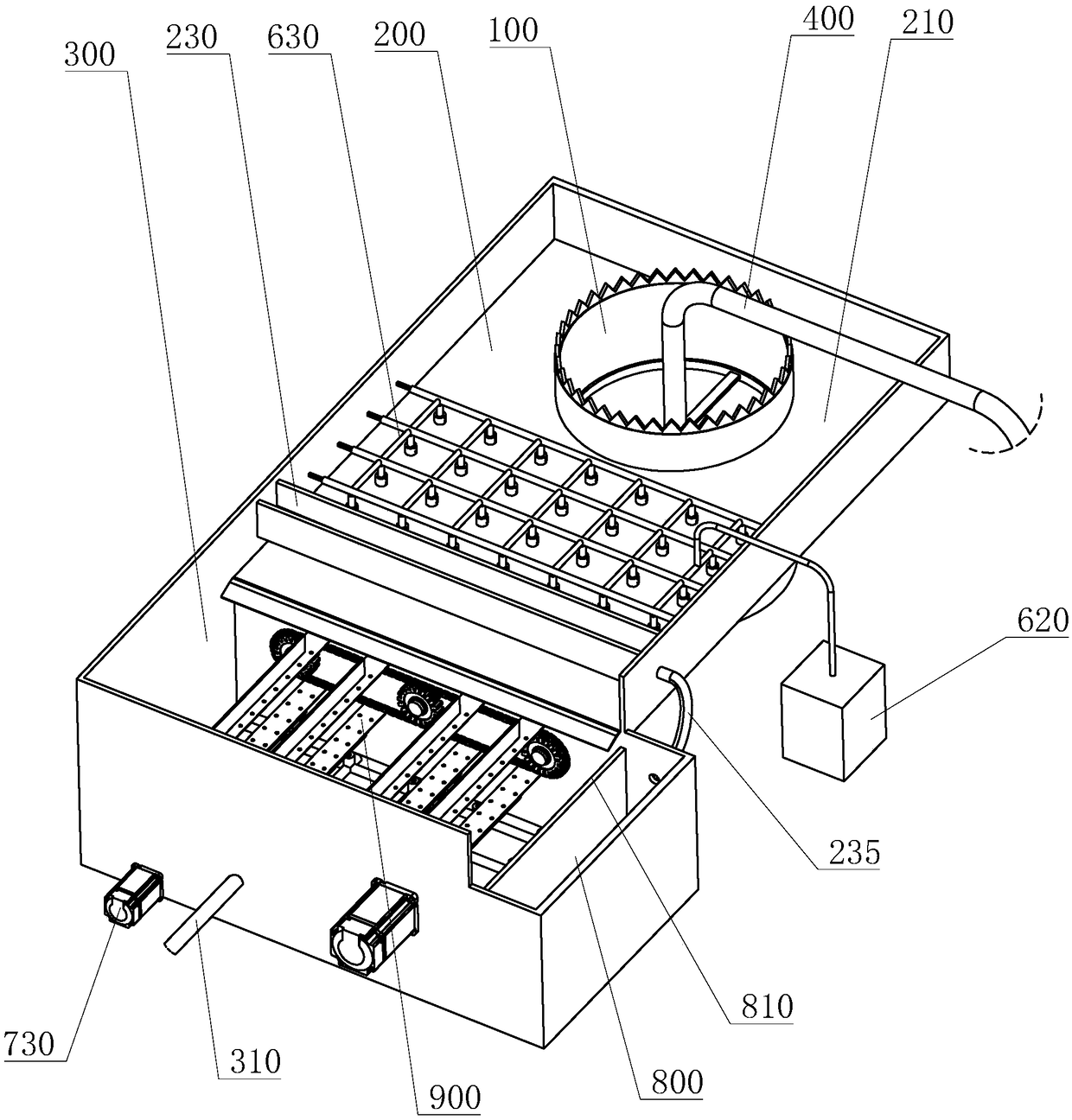

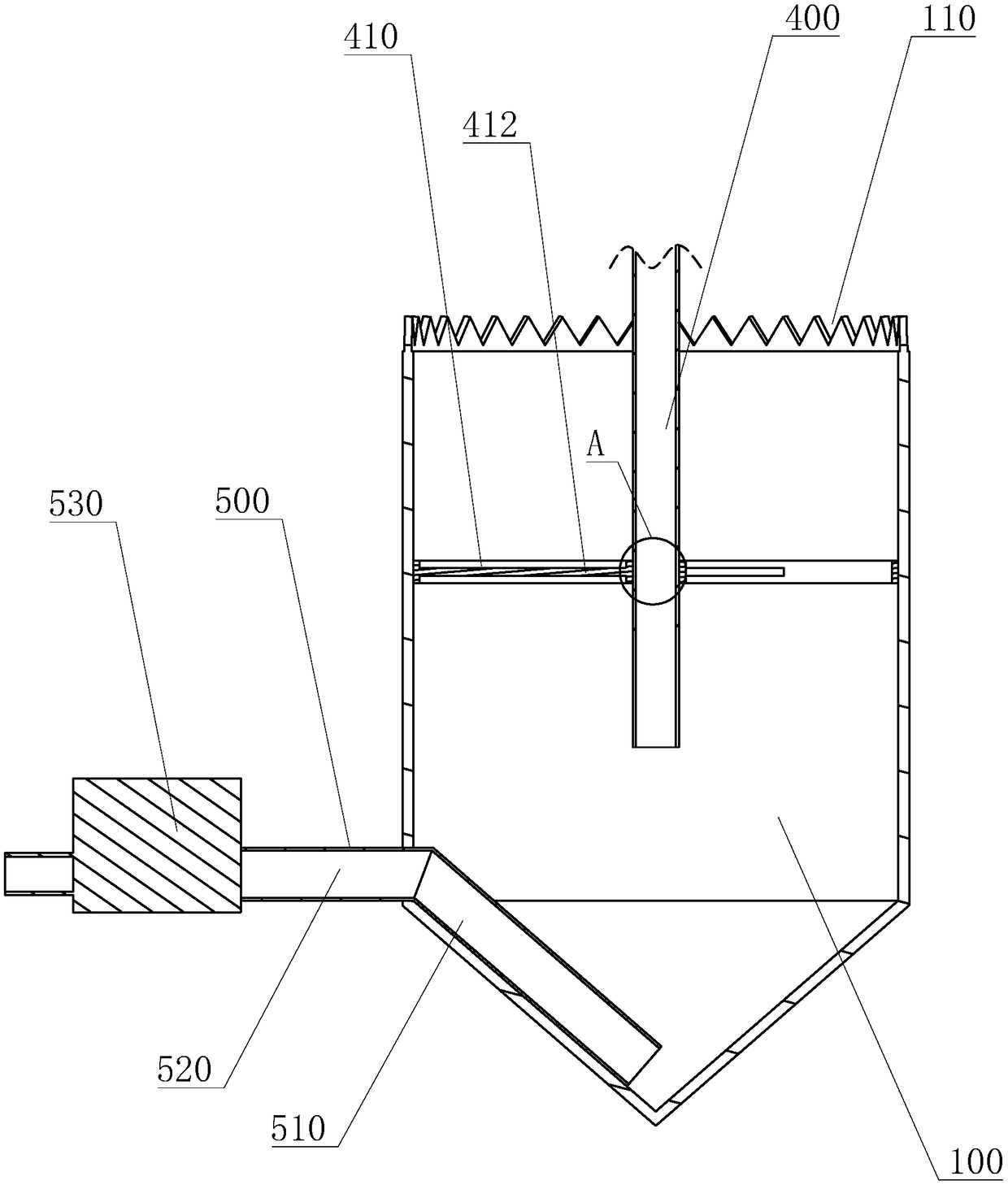

[0040] See attached figure 1 , a sedimentation air flotation compound tank, mainly including a sedimentation tank 100, a guide tank 200 and an air flotation tank 300. Wherein, the guide tank 200 is arranged on the outside of the sedimentation tank 100, and the bottom surface of the guide tank 200 is lower than the top edge of the sedimentation tank 100, that is, the overflowing sewage in the sedimentation tank 100 will fall into the guide tank 200; The tank 300 is arranged on one side of the settling tank 100 , and one side of the air flotation tank 300 communicates with the guide tank 200 , that is, the sewage in the guide tank 200 can be discharged into the air flotation tank 300 .

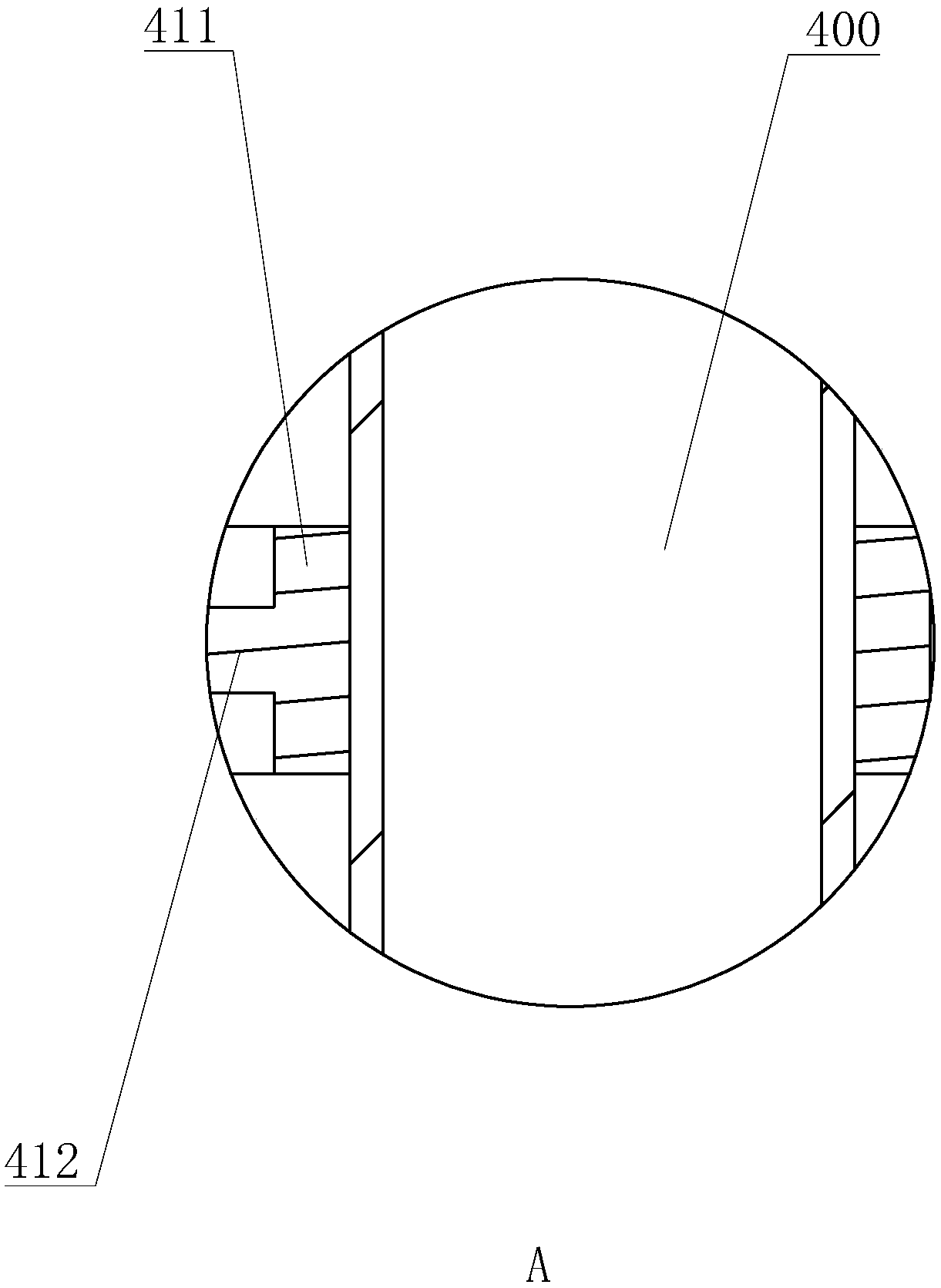

[0041] See attached figure 1 And attached figure 2 , the sedimentation tank 100 is a circular tank, and the bottom surface of the sedimentation tank 100 is a tapered surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com