Multi-stage thermal washing and screening method and system for oily sludge-containing impurities

A screening and hot washing technology, which is applied to liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of high labor intensity, long time consumption, waste, etc., to improve processing capacity and improve cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

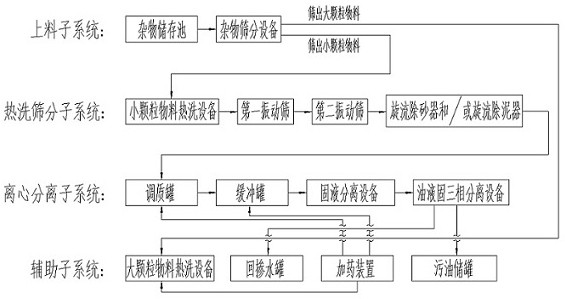

[0071]The invention discloses a multi-stage hot-washing and screening method for oily sludge, which screens and classifies materials of different sizes in the oily sludge and performs different degreasing treatments respectively, and removes the dirty oil attached to the debris. Wash, including the following steps:

[0072] S1: Initial screening of oily sludge debris;

[0073] S2: Carry out hot washing and multi-stage screening of the under-screened materials (small particle materials screened out, such as stones, gravel, sand, mud, etc.) for the first screening until the processing requirements are met. The materials processed by the first-stage screening treatment in the first-stage screening treatment are the discharge materials (referring to the discharged small particle materials) of the under-screen material heat washing treatment, and the materials processed by any next-level screening treatment are the materials processed by the previous one. The under-screened materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com