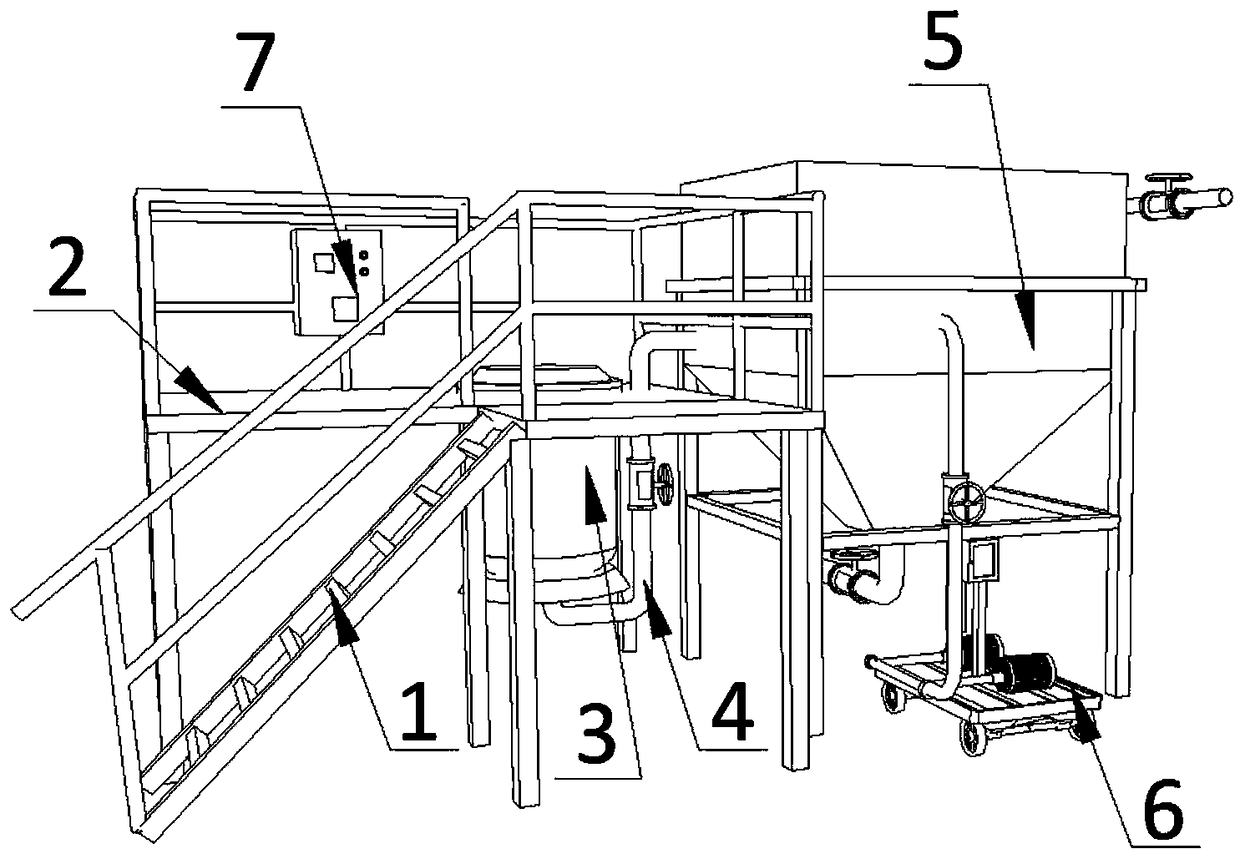

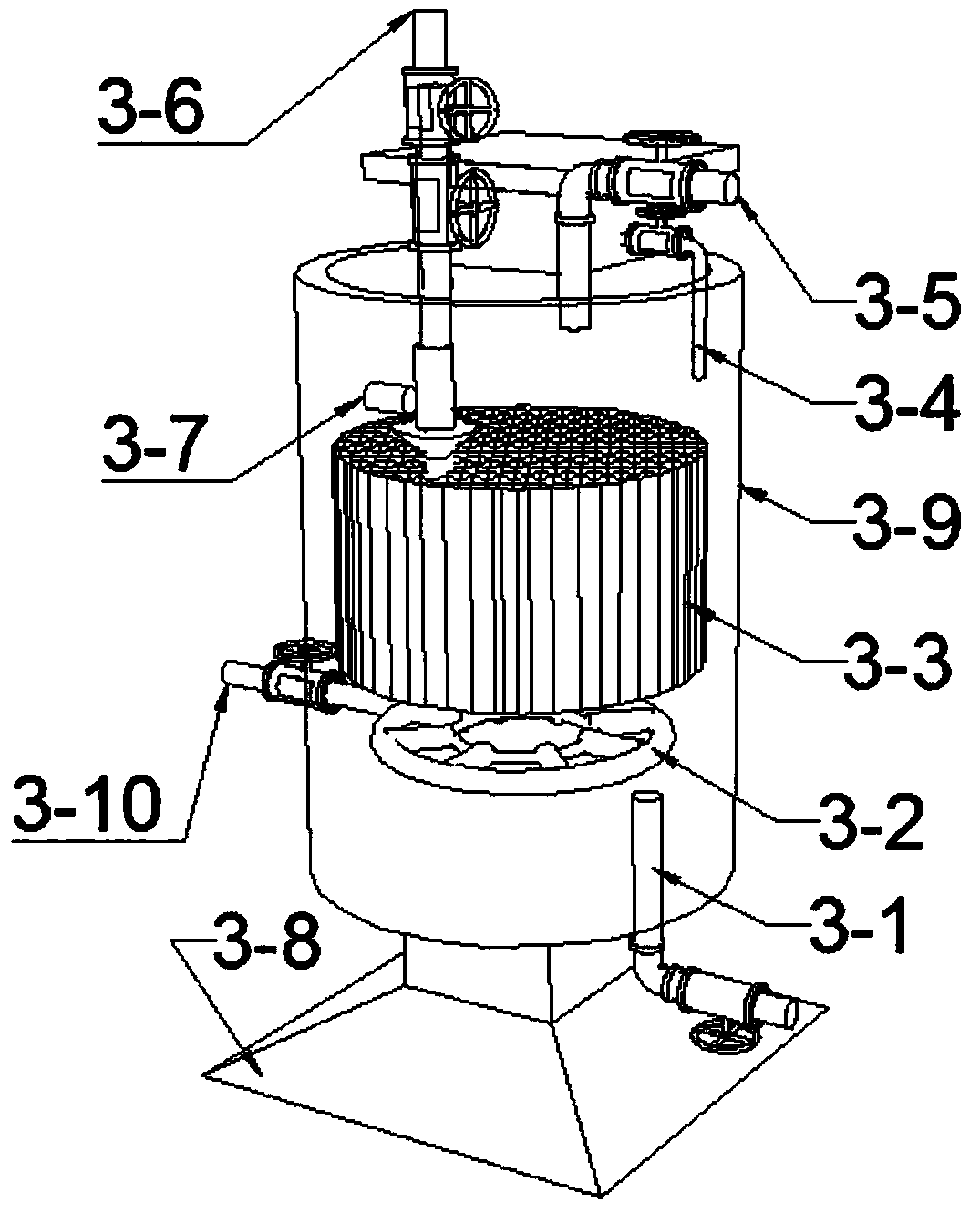

Treatment device for rural domestic refuse leachate

A domestic garbage and treatment device technology, which is applied in the direction of filtration treatment, contaminated groundwater/leachate treatment, special treatment targets, etc., can solve the problems of high manufacturing cost, complex device structure, unfavorable and convenient treatment of rural domestic garbage leachate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

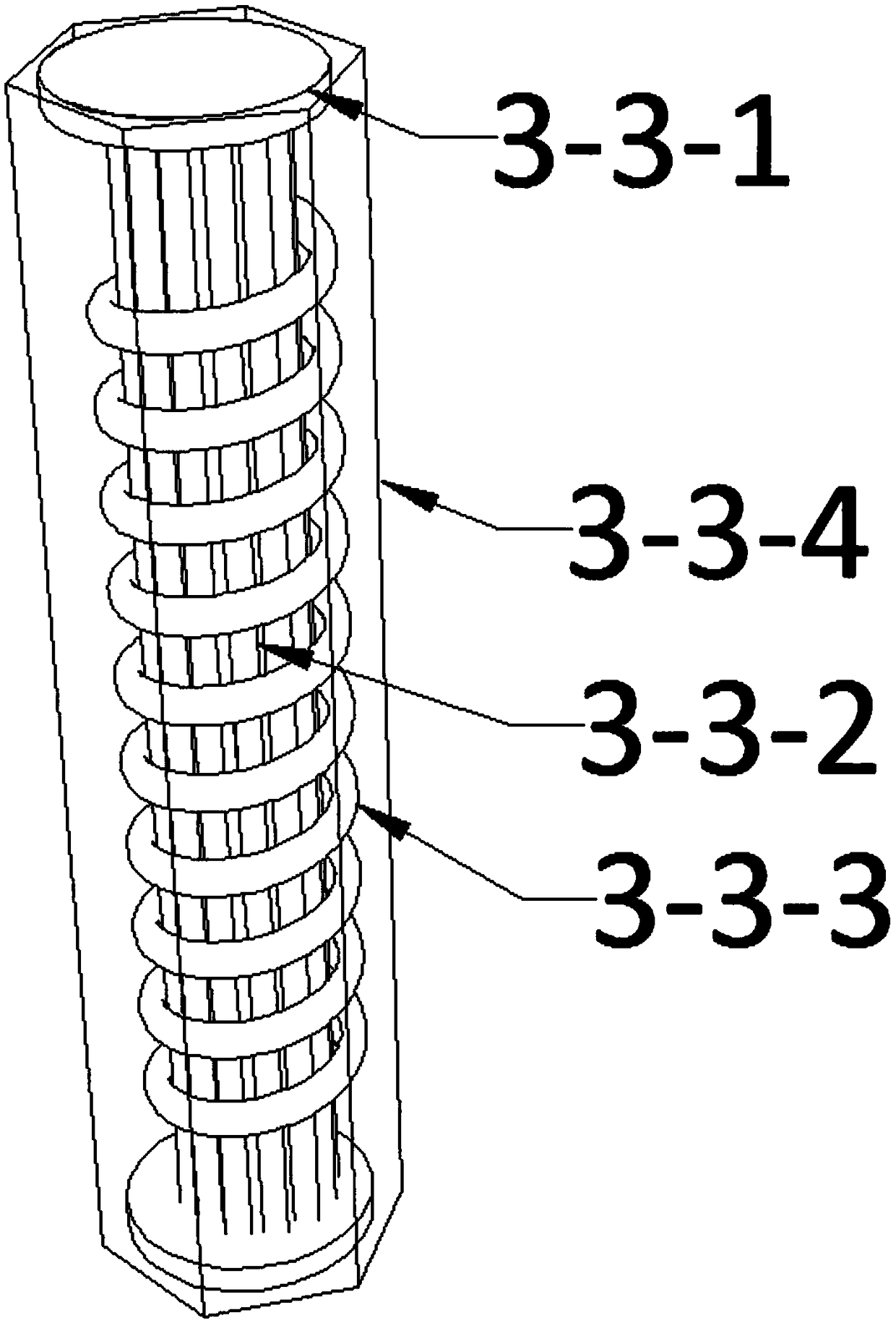

[0064] The heating tube 3-3-3 of the present invention is prepared according to the following steps, and is calculated in parts by weight:

[0065] Step 1: In the multi-tank reactor, add 341.0 parts of distilled water and 133.3 parts of 3-methylundecanonitrile, start the mixer in the multi-tank reactor, set the speed at 134rpm, and start the steam seal in the multi-tank reactor Steam heat exchanger, raise the temperature to 149.0°C, add 2-methoxy-5-methyl-4-[(4-methyl-2-nitrophenyl)azo]benzenediazo (T-4 ) Tetrachlorozincate (2:1) 136.2 parts, stirred evenly, reacted for 126.3 minutes, added 132.6 parts of ethyl 3-methylthiobutyrate, and the flow rate was 125.1m 3 / min of fluorine gas for 126.3 minutes; then add 135.2 parts of the golden leuco body in the multi-pot reactor, start the vapor-sealed steam heat exchanger in the multi-pot reactor again, raise the temperature to 166.2°C, keep it warm for 126.6 minutes, add 2,2'-[(1-methylethylene)bis[[2-(2-propenyl)-4,1-phenylene]ox...

Embodiment 2

[0071] The heating tube 3-3-3 of the present invention is prepared according to the following steps, and is calculated in parts by weight:

[0072] Step 1: In the multi-pot reactor, add 566.2 parts of distilled water and 175.5 parts of 3-methylundecanonitrile, start the mixer in the multi-pot reactor, set the speed at 180rpm, and start the steam seal in the multi-pot reactor Steam heat exchanger, raise the temperature to 150.2°C, add 2-methoxy-5-methyl-4-[(4-methyl-2-nitrophenyl)azo]benzenediazo (T-4 ) Tetrachlorozincate (2:1) 245.1 parts, stirred evenly, reacted for 137.5 minutes, added 149.7 parts of ethyl 3-methylthiobutyrate, and the flow rate was 166.7m 3 / min of fluorine gas for 137.5 minutes; then add 192.9 parts of golden leuco body into the multi-pot reactor, start the vapor seal steam heat exchanger in the multi-pot reactor again, raise the temperature to 199.1°C, keep it warm for 137.7 minutes, add 2,2'-[(1-methylethylene)bis[[2-(2-propenyl)-4,1-phenylene]oxymethyle...

Embodiment 3

[0078] The heating tube 3-3-3 of the present invention is prepared according to the following steps, and is calculated in parts by weight:

[0079] Step 1: In the multi-pot reactor, add 341.9 parts of distilled water and 133.9 parts of 3-methylundecanonitrile, start the mixer in the multi-pot reactor, set the speed at 134rpm, and start the steam seal in the multi-pot reactor Steam heat exchanger, raise the temperature to 149.9°C, add 2-methoxy-5-methyl-4-[(4-methyl-2-nitrophenyl)azo]benzenediazo (T-4 ) Tetrachlorozincate (2:1) 136.9 parts, stirred evenly, reacted for 126.9 minutes, added 132.9 parts of ethyl 3-methylthiobutyrate, and the flow rate was 125.9m 3 / min of fluorine gas for 126.9 minutes; then add 135.9 parts of golden leuco body into the multi-pot reactor, start the vapor seal steam heat exchanger in the multi-pot reactor again, raise the temperature to 166.9°C, keep it warm for 126.9 minutes, add 2,2'-[(1-methylethylene)bis[[2-(2-propenyl)-4,1-phenylene]oxymethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com