Mobile composting odor collection system

A collection system and mobile technology, which is applied in the field of mobile composting odor collection system, can solve the problems that continuous operation cannot be realized, the air environment has a great impact, and odor cannot be suppressed, so as to avoid the escape of odor and avoid odor The effect of air escaping and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

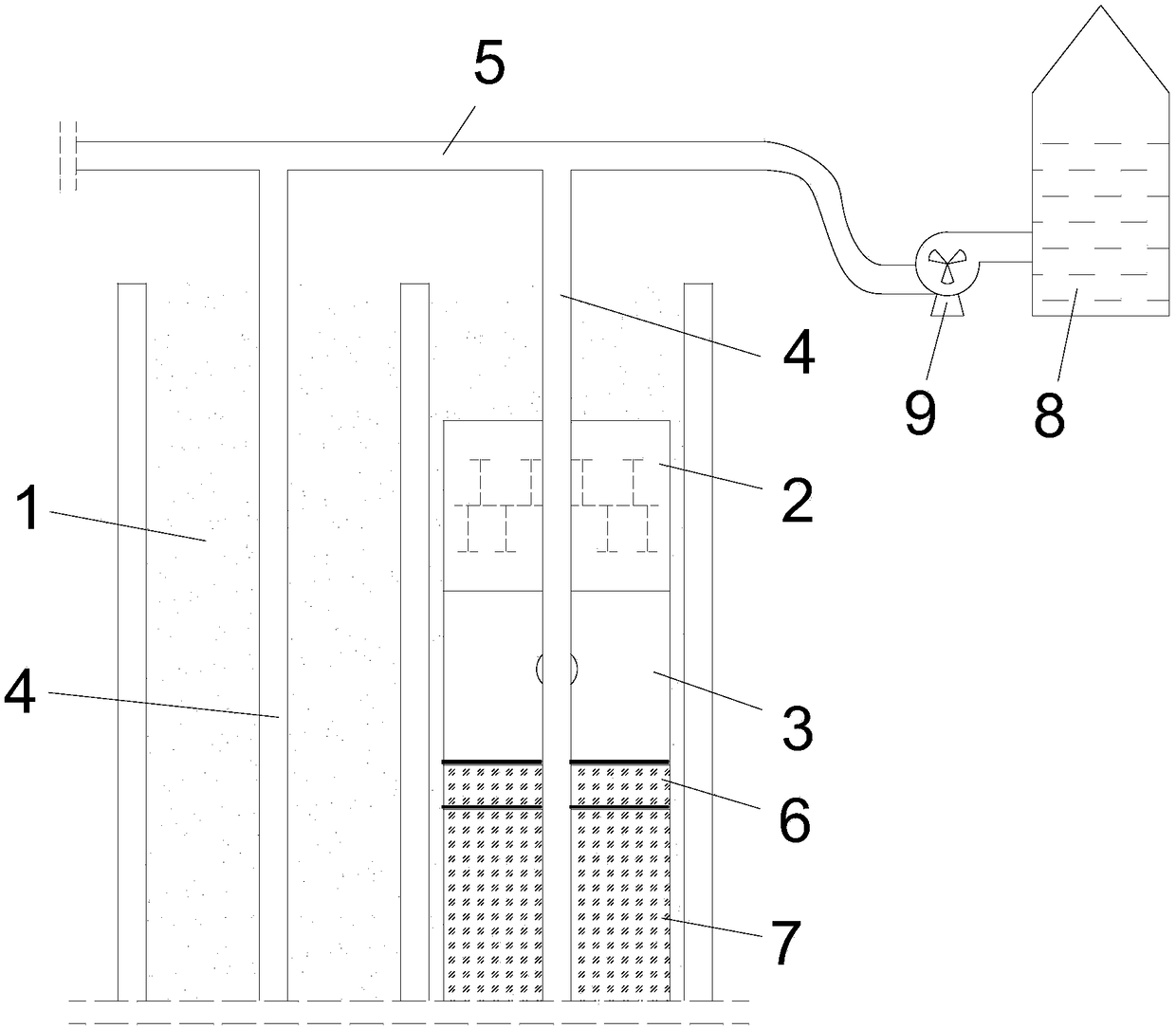

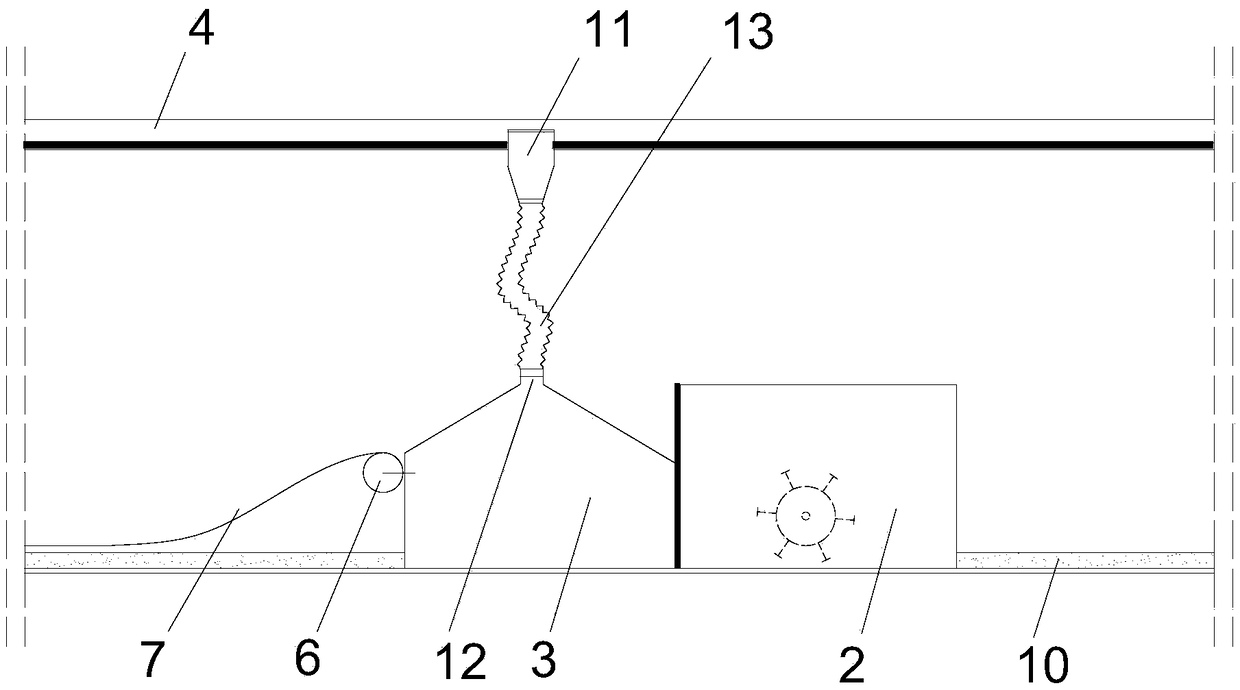

[0022] In order to better understand the present invention, the technical scheme of the present invention will be further described below in conjunction with embodiment and accompanying drawing (as figure 1 , 2 , 3 shown).

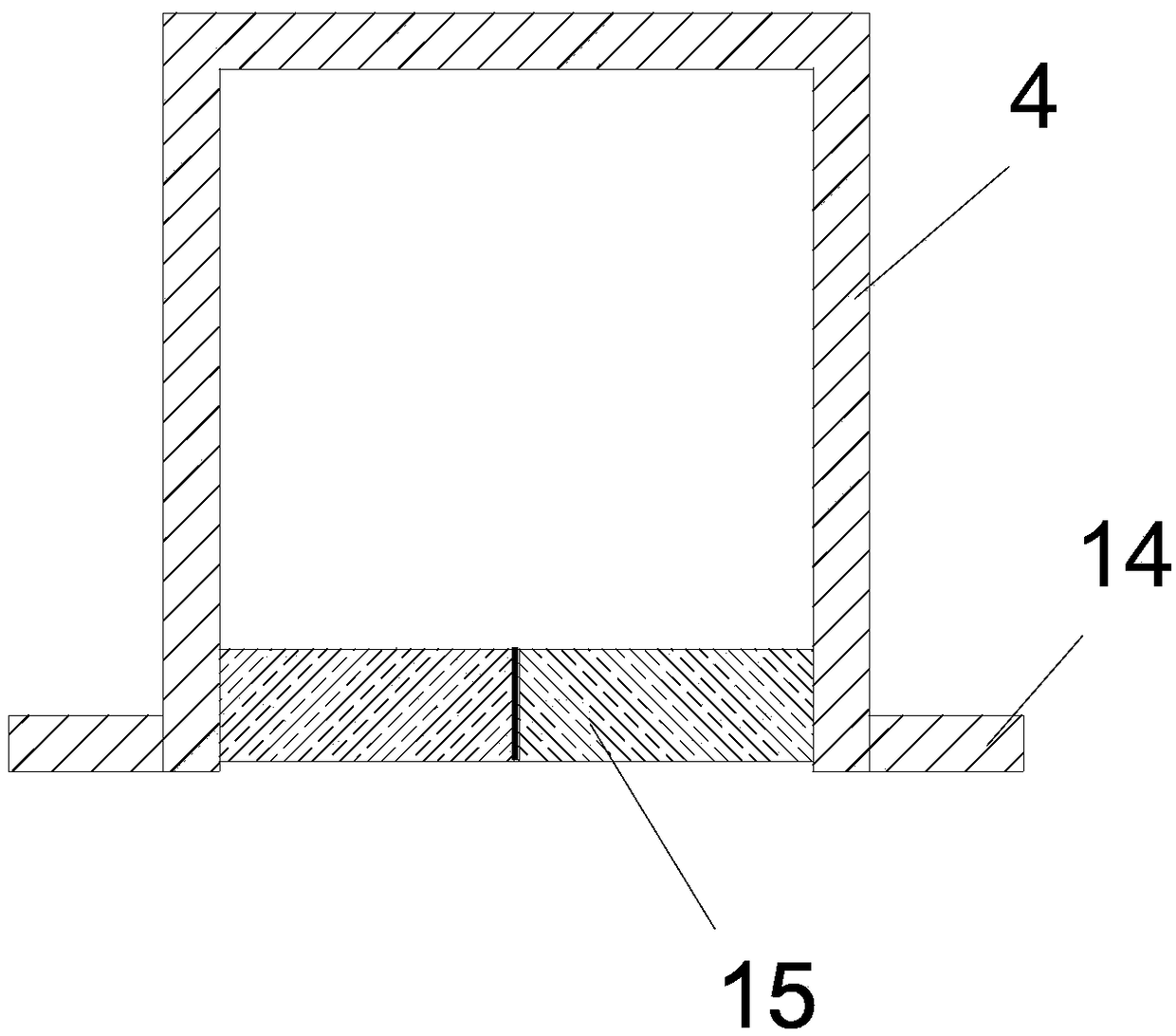

[0023] A mobile composting odor collection system, the system includes an exhaust pipeline and a gas collection device; the exhaust pipeline includes an exhaust main pipe 5 and some exhaust branch pipes 4 (exhaust branch pipe 4 and fermenter 1 same number), the plurality of exhaust branch pipes 4 are respectively installed directly above the corresponding fermentation tank 1, one end of the exhaust branch pipe 4 is blocked, and the other end is connected with the exhaust main pipe 5. On the exhaust main pipe 5 An exhaust fan 9 is provided; the exhaust branch pipe 4 is a channel steel structure with its opening facing downwards, and both sides of the opening are provided with sealing strips 15 that cooperate with each other to form a self-closing structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com