Shiny-leaved yellowhorn fruit vinegar and preparation method thereof

A technology of fruit vinegar and Wenguan, applied in the field of Wenguan fruit vinegar and its preparation, can solve the problems of singleness, insufficient development degree, small application aspects, etc., and achieve the effects of simple process, increased development degree and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

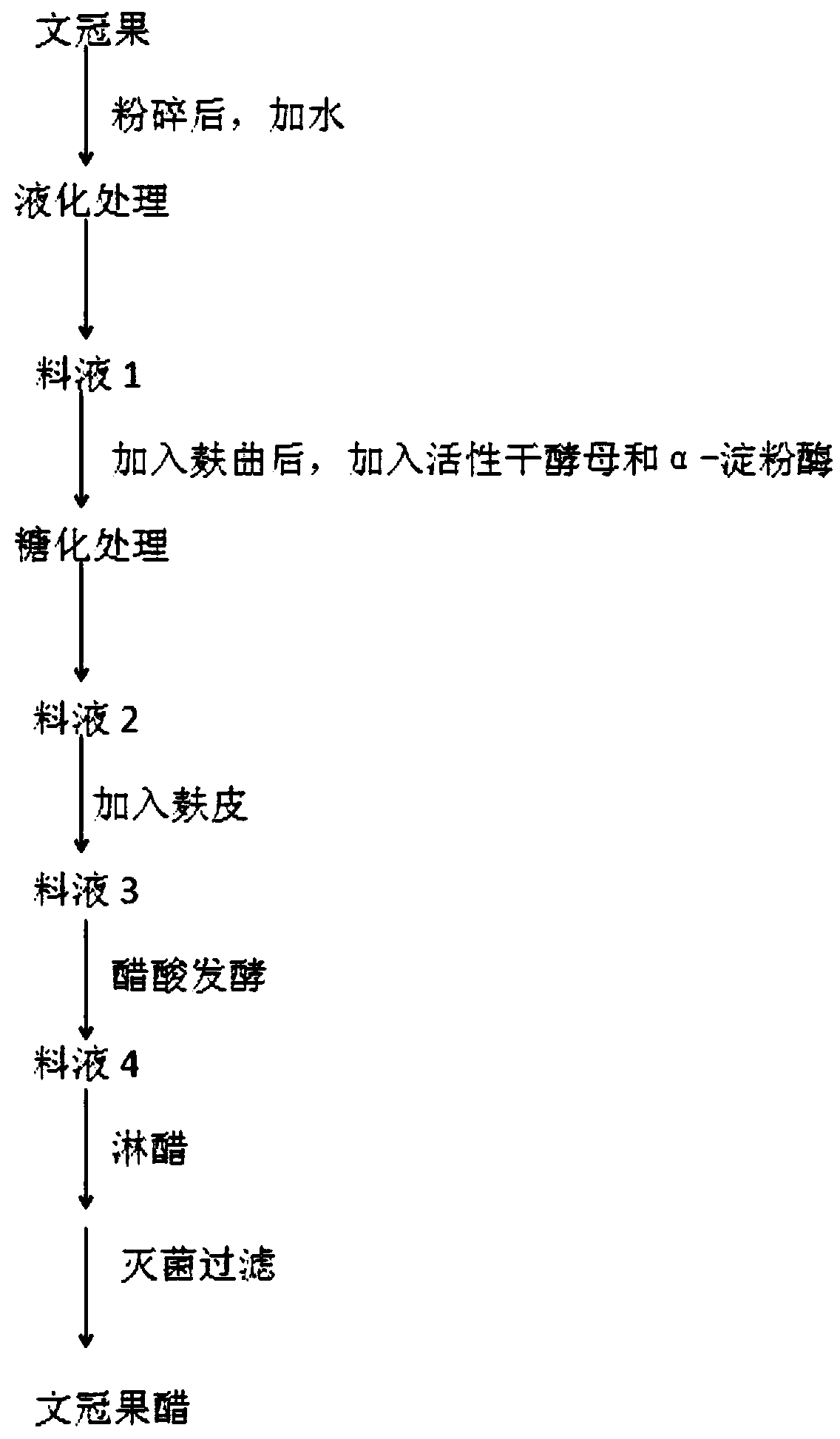

Image

Examples

Embodiment 1

[0039] Raw materials: 9kg sorbifolia, 27kg water, 1.8kg bran, 9g active dry yeast, 20g α-amylase and 45kg bran.

[0040] process such as figure 1 As shown, the specific operation steps are as follows:

[0041] (1) Liquefaction: After crushing 9 kg of Xanthos sorbifolium, add 27 kg of water, boil and cool to 35° C. to obtain material liquid 1.

[0042] (2) Saccharification: Add 1.8kg bran koji to feed liquid 1, mix well, add 9g active dry yeast and 20g α-amylase, and saccharify at 35°C for 8 days to obtain feed liquid 2; pay attention to stirring during this process , changes in ventilation and alcohol level.

[0043] (3) Expanding the song: adding feed liquid 2 to 45kg of bran, stirring evenly to obtain feed liquid 3.

[0044] (4) Acetic acid fermentation: Feed liquid 3 was subjected to acetic acid fermentation for 32 days at 38°C to obtain feed liquid 4.

[0045] (5) After the feed liquid 4 is drenched with vinegar, the first natural precipitation is carried out, and then...

Embodiment 2

[0048] Raw materials: 11kg sorbifolia, 33kg water, 2.2kg bran, 11g active dry yeast, 20g α-amylase and 55kg bran.

[0049] The specific operation steps are as follows:

[0050] (1) Liquefaction: After crushing 11 kg of sorbifolia, add 33 kg of water, boil and cool to 38° C. to obtain material liquid 1.

[0051] (2) Saccharification: Add 2.2kg bran koji to feed liquid 1, mix well, add 11g active dry yeast and 20g α-amylase, and saccharify at 38°C for 7 days to obtain feed liquid 2; pay attention during the saccharification process Stirring, aeration and changes in alcohol level.

[0052] (3) Expanding the song: adding feed liquid 2 to 55kg bran, stirring evenly to obtain feed liquid 3.

[0053] (4) Acetic acid fermentation: Feed liquid 3 was subjected to acetic acid fermentation at 45° C. for 28 days to obtain feed liquid 4 .

[0054] (5) After the feed liquid 4 was drenched with vinegar, the first natural precipitation was carried out, and then sterilized at 90° C., and final...

Embodiment 3

[0057] Raw materials: 10kg sorbifolia, 30kg water, 2kg bran, 10g active dry yeast, 20g α-amylase and 50kg bran.

[0058] The specific operation steps are as follows:

[0059] (1) Liquefaction: After crushing 10 kg of sorbifolia, add 30 kg of water, boil and cool to 36° C. to obtain material liquid 1.

[0060] (2) Saccharification: Add 2kg of bran koji to material liquid 1, mix well, add 10g of active dry yeast and 20g of α-amylase, and saccharify at 36°C for 8 days to obtain material liquid 2; pay attention to stirring during the saccharification process , changes in ventilation and alcohol level.

[0061] (3) Expanding the song: adding feed liquid 2 to 50kg of bran, stirring evenly to obtain feed liquid 3.

[0062] (4) Acetic acid fermentation: Feed liquid 3 was subjected to acetic acid fermentation at 40° C. for 30 days to obtain feed liquid 4 .

[0063] (5) After the feed liquid 4 is drenched with vinegar, the first natural precipitation is carried out, and then steriliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com