Subway tunnel shield end reinforcing method

A technology of tunnel shield and end head, which is applied in tunnels, earthwork drilling, infrastructure engineering, etc., can solve the problems of shield starting, construction and reinforcement, etc., to ensure safety and short construction period. , the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

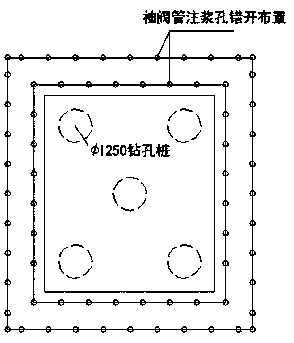

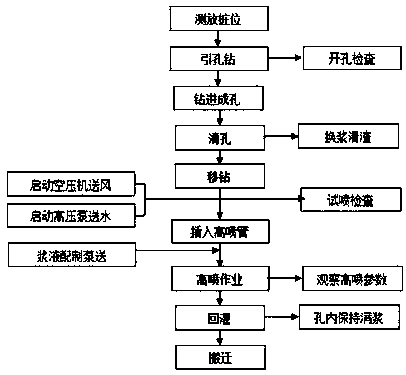

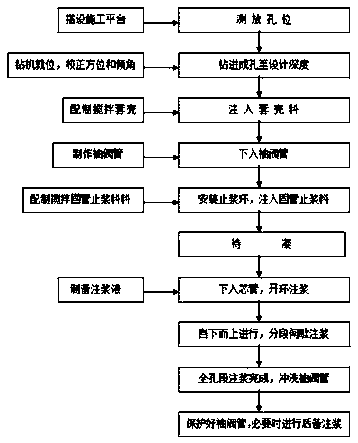

[0033] see Figure 1-Figure 3 , in an embodiment of the present invention, a subway tunnel shield end reinforcement method, including shield end reinforcement, water supply pipe reinforcement and bridge pier reinforcement, the shield end reinforcement method is divided into origination shaft reinforcement and receiving shaft reinforcement ; The reinforcement method of the originating shaft is to adopt φ800@600 high-pressure jet grouting piles for reinforcement, and the edge of the reinforcement area is constructed with a 1000mm ground connection wall for the reinforcement of the closed end; the reinforcement method of the receiving shaft is to adopt φ800@600 high-pressure jet grouting piles, Among them, the reinforcement length is 9m, the width is 3m extending from the shield hole circle, and the depth range is 3m upward and 3m downward, with strong reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com