Fabricated self-resetting basic system

A prefabricated and basic technology, applied in the direction of infrastructure engineering, wine cellars, building components, etc., can solve the problems of only usable foundation, missing connections, waste, etc., and achieve improved space utilization, simple construction technology, and easy stacking and storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

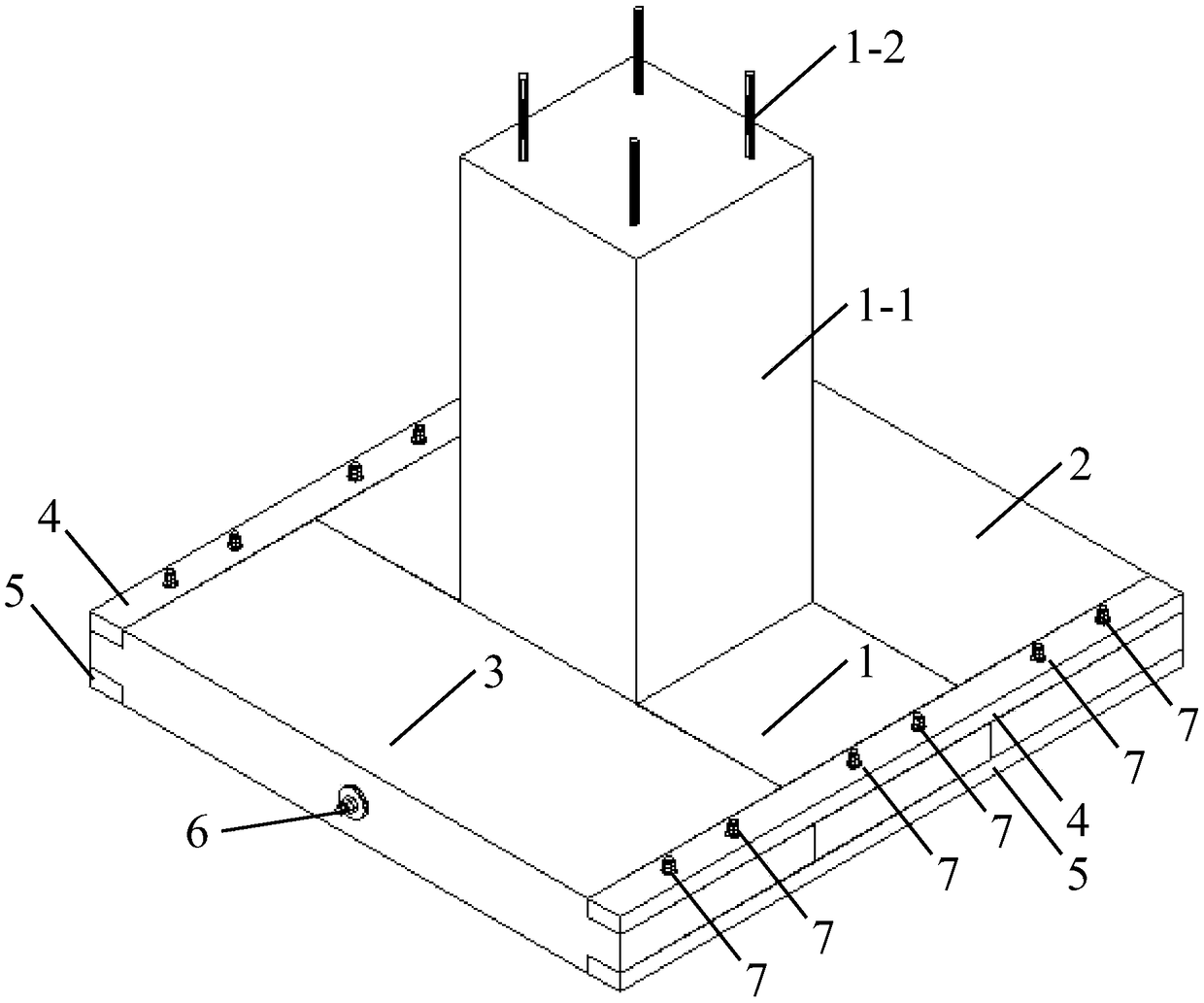

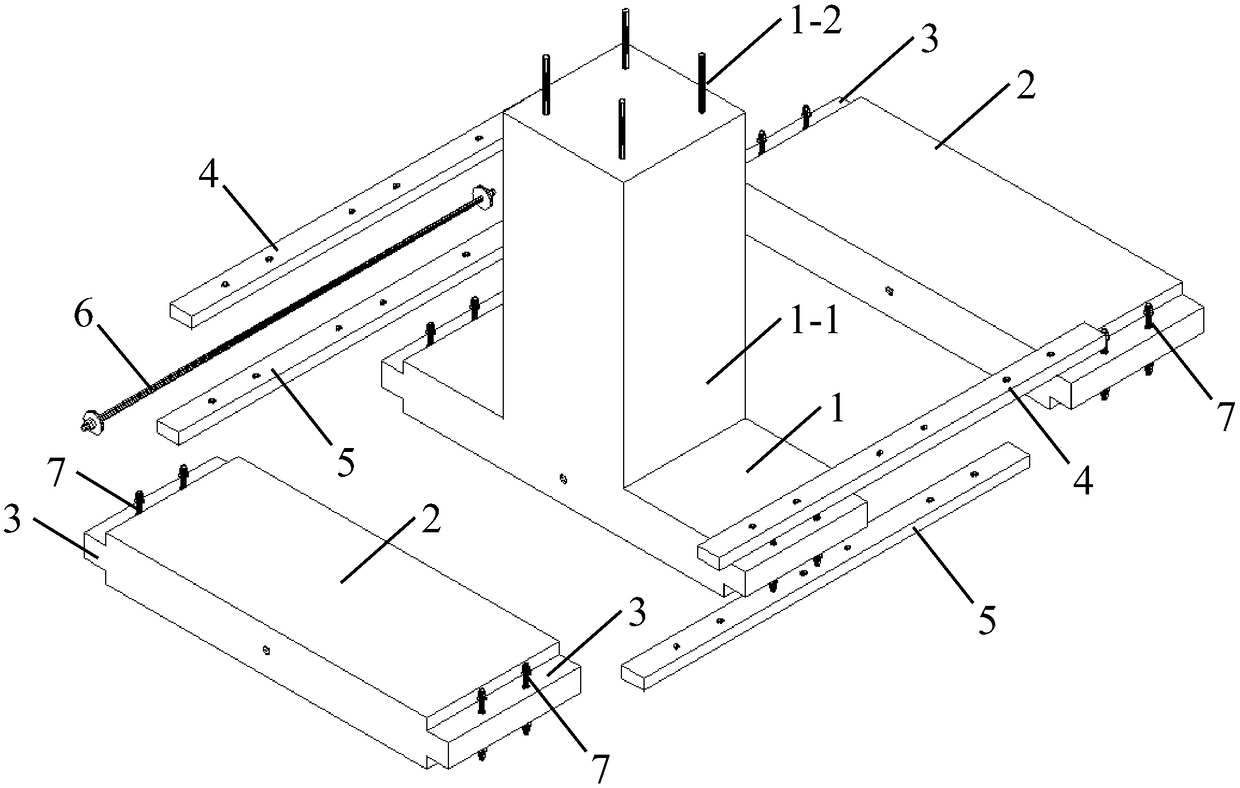

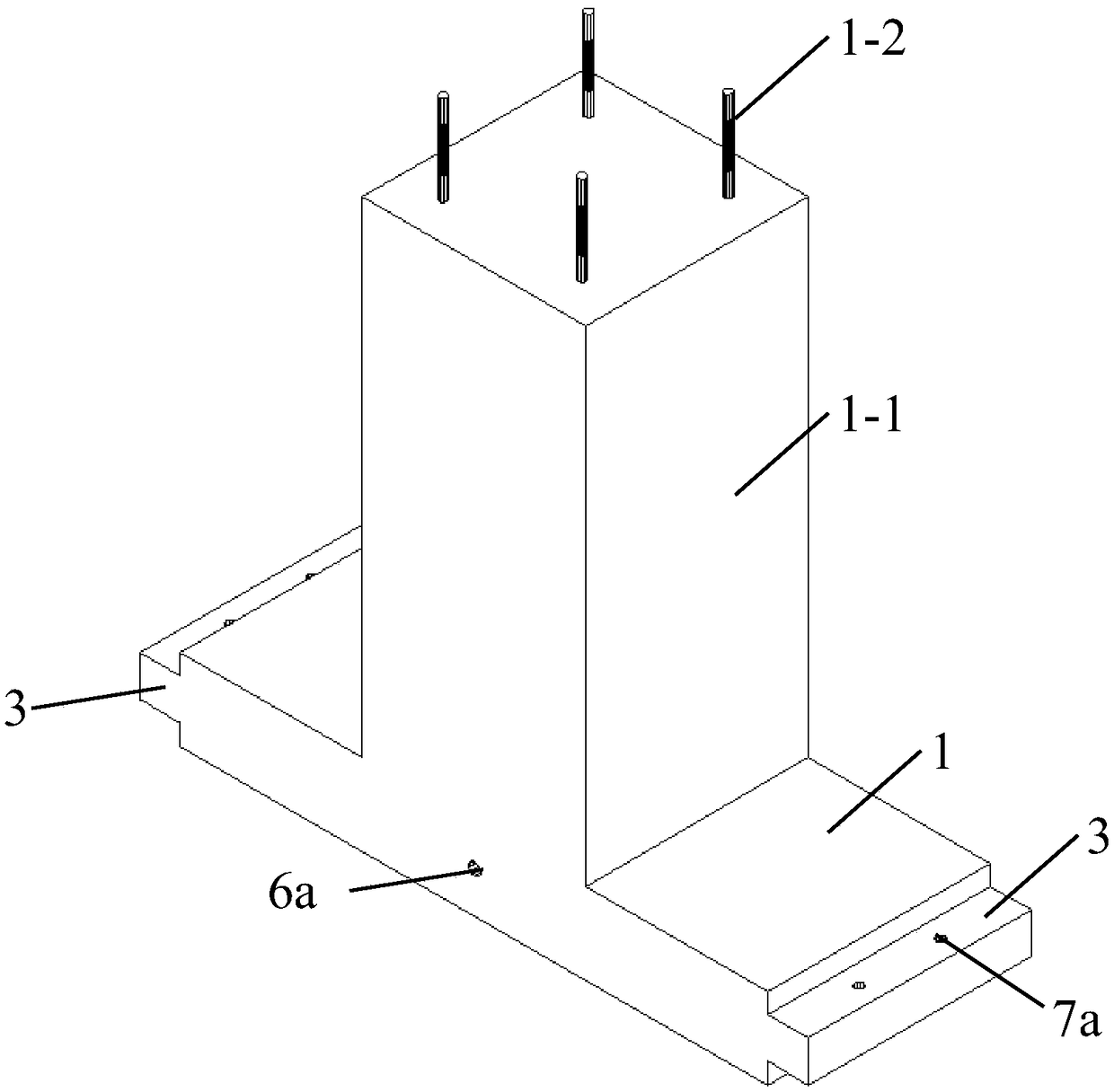

[0036] combine Figure 1 to Figure 4 As shown, an assembled self-recovering foundation system includes a main foundation unit 1 and two sub-basic units 2 spliced on the sides of the main foundation unit; Symmetrical stepped sinker 3, the stepped sinker 3 has installation through holes 7a and 7b through up and down; the upper beam 4 is fitted in the stepped sinker 3 on the upper side, and the stepped sinker 3 on the lower side The lower crossbeam 5 is fitted inside; the corresponding upper crossbeam 4 and lower crossbeam 5 on each side are connected by steel bolts 7; the middle openings 6a and 6b of the main foundation unit 1 and the auxiliary foundation unit 2 are pre-tensioned The shape-memory alloy screw rod 6 of the pull connects the main and auxiliary foundations together. The main basic unit 1 and the auxiliary basic unit 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap