Fabricated stiffness-varied transverse connection energy dissipation piece and installation method

A technology of horizontal connection and variable stiffness, which is applied in the direction of building components, protective buildings/shelters, walls, etc., and can solve the problem of not being able to combine energy consumption, load bearing, stiffness jump and energy consumption load bearing sub-function design, and lateral stiffness And problems such as reduced bearing capacity and large bending deformation, to achieve the effect of excellent hysteretic energy dissipation performance, little influence of external environment, and strong deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

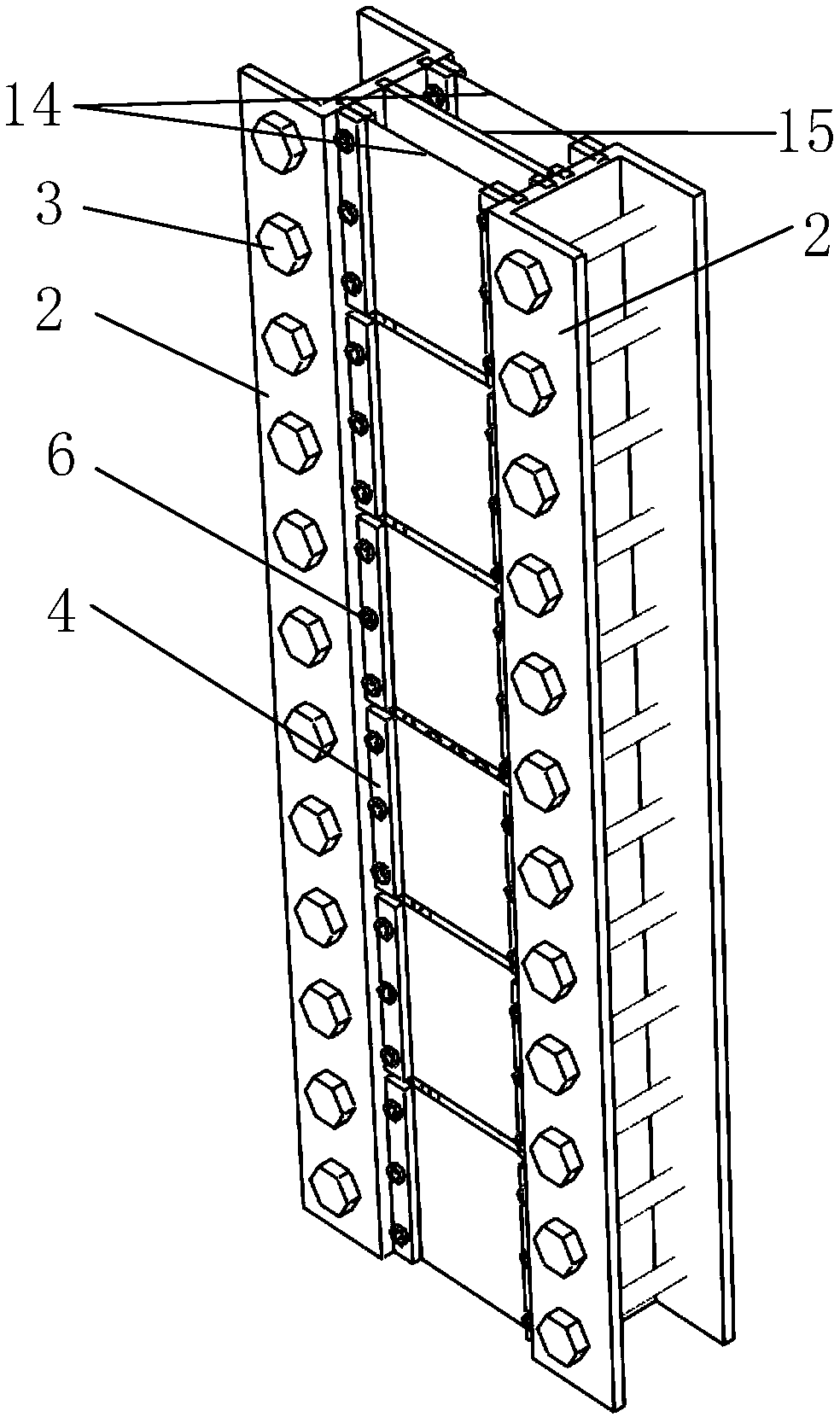

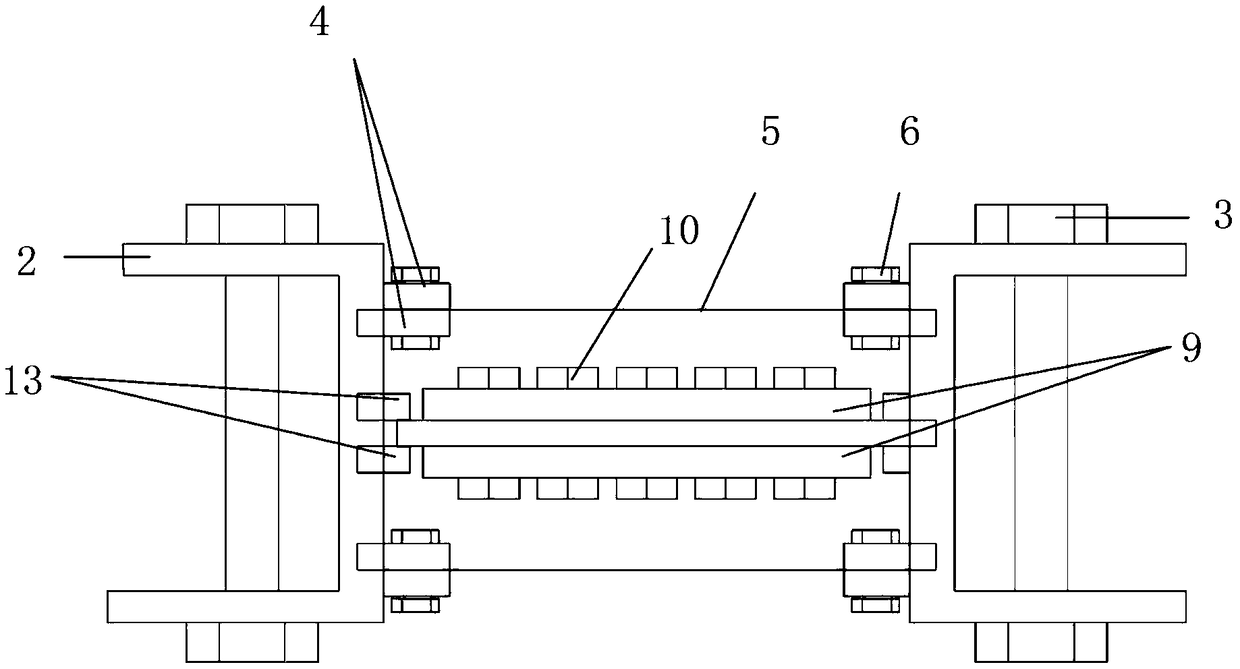

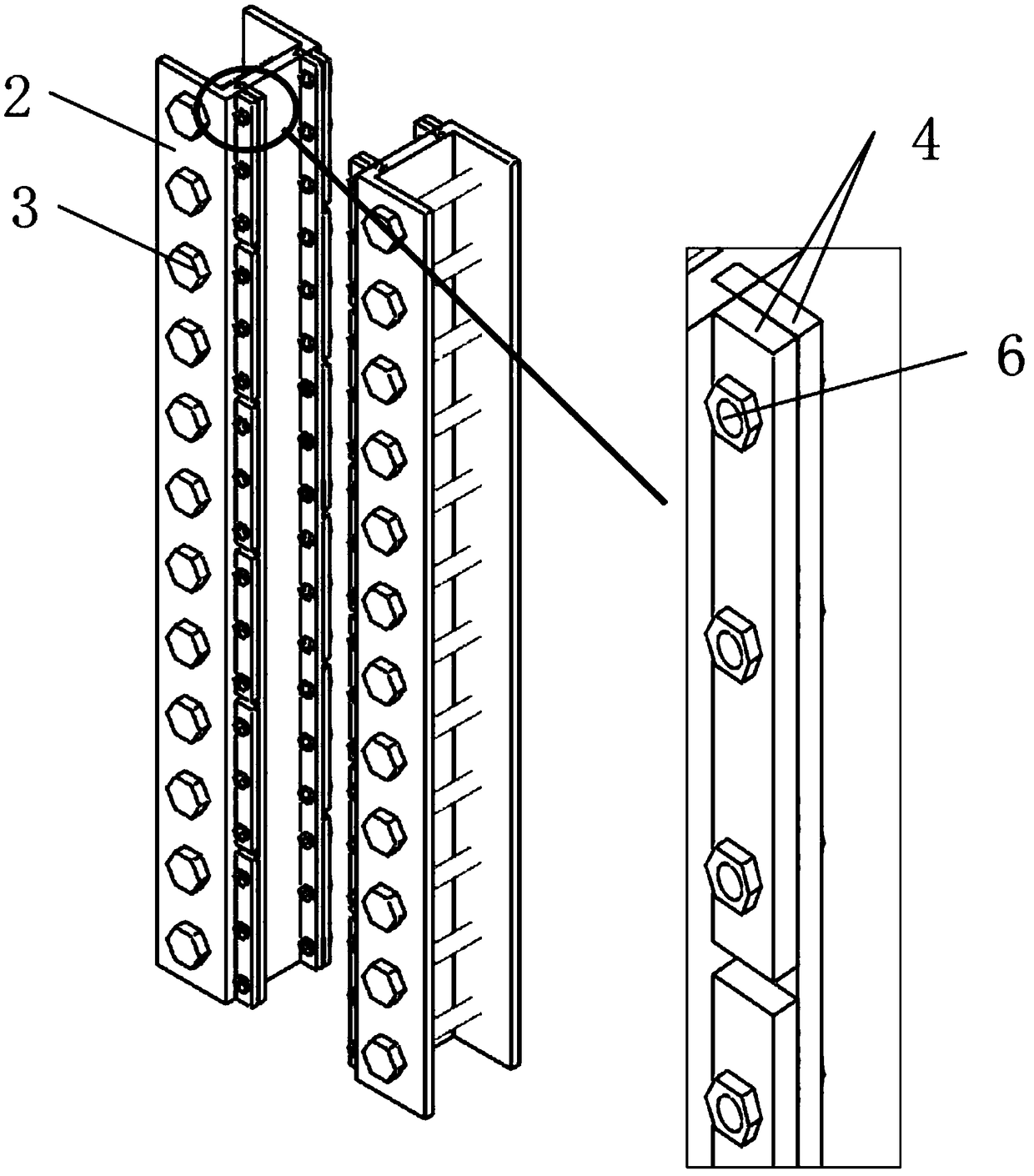

[0042] Such as figure 1 As shown, an assembled variable-stiffness transverse connection energy-consuming part according to the present invention includes a lifting area 15 , an energy-dissipating area 14 and left and right connecting end plates 2 . The energy dissipation area includes mild steel energy dissipation area steel plates 5 , bolts 6 and bolt connection plates 4 . The lifting area includes an upper steel plate 7, a lower steel plate 8, bolt holes 11 in the upper steel plate in the lifting area, bolt holes 12 in the lower steel plate in the lifting area, two front and rear buckling restraint plates 9, high-strength bolts 10 and sliding rails 13.

[0043] Such as figure 2 As shown, it is a schematic diagram of the top view structure of the present invention, the energy dissipation area 14 is located outside the damper, and the lifting area 15 is located inside the damper. The bolted connection plates inside the energy dissipation area 14 are at the same height as th...

Embodiment 2

[0048] A method for installing the assembly-type variable-stiffness transverse connection energy-consuming parts, the steps are as follows:

[0049] (1) Reserved bolt holes: reserve the designed bolt hole size on the steel plate in the energy dissipation area, the steel plate in the lifting area, the buckling restraint plate and the bolt connection plate in the energy dissipation area;

[0050] (2) Welded steel plates: respectively weld the bolted connecting plates inside the energy dissipation area to the left and right connecting end plates, and the steel plates in the lifting area are respectively welded to the left and right connecting end plates.

[0051] (3) Bolt connection: The steel plate in the lifting area is connected with the buckling restraint plate placed parallel to the front and rear with high-strength bolts, and then the steel plate in the energy-dissipating area is connected with the outer bolted connection plate through bolts.

[0052] (4) Connecting shear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com