Nozzle blade design for a variable nozzle turbine

A nozzle blade, turbine technology, applied in the direction of mechanical equipment, blade support elements, combustion engines, etc., can solve the problems of pressure loss turbine efficiency and performance adverse effects, total pressure loss increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

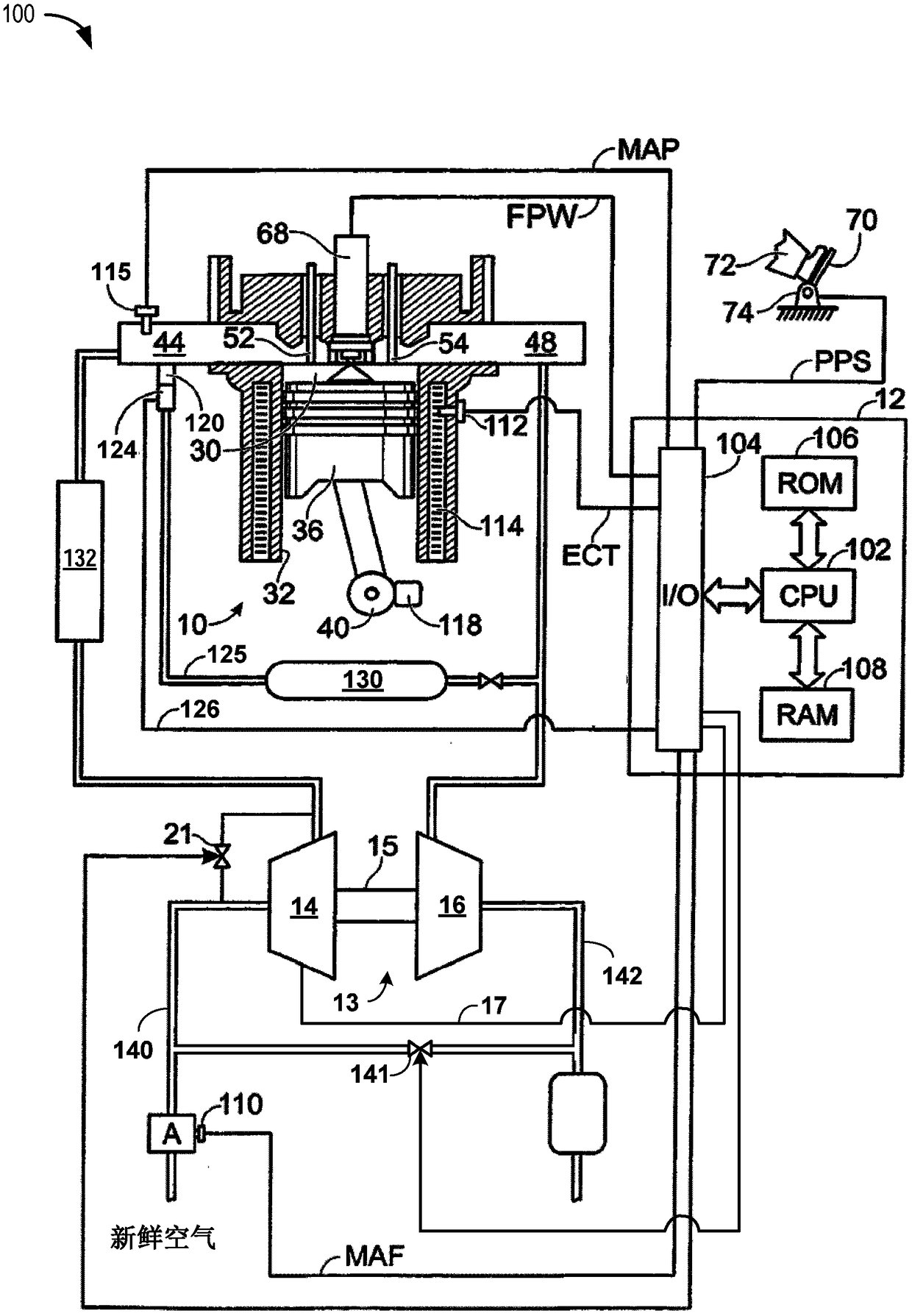

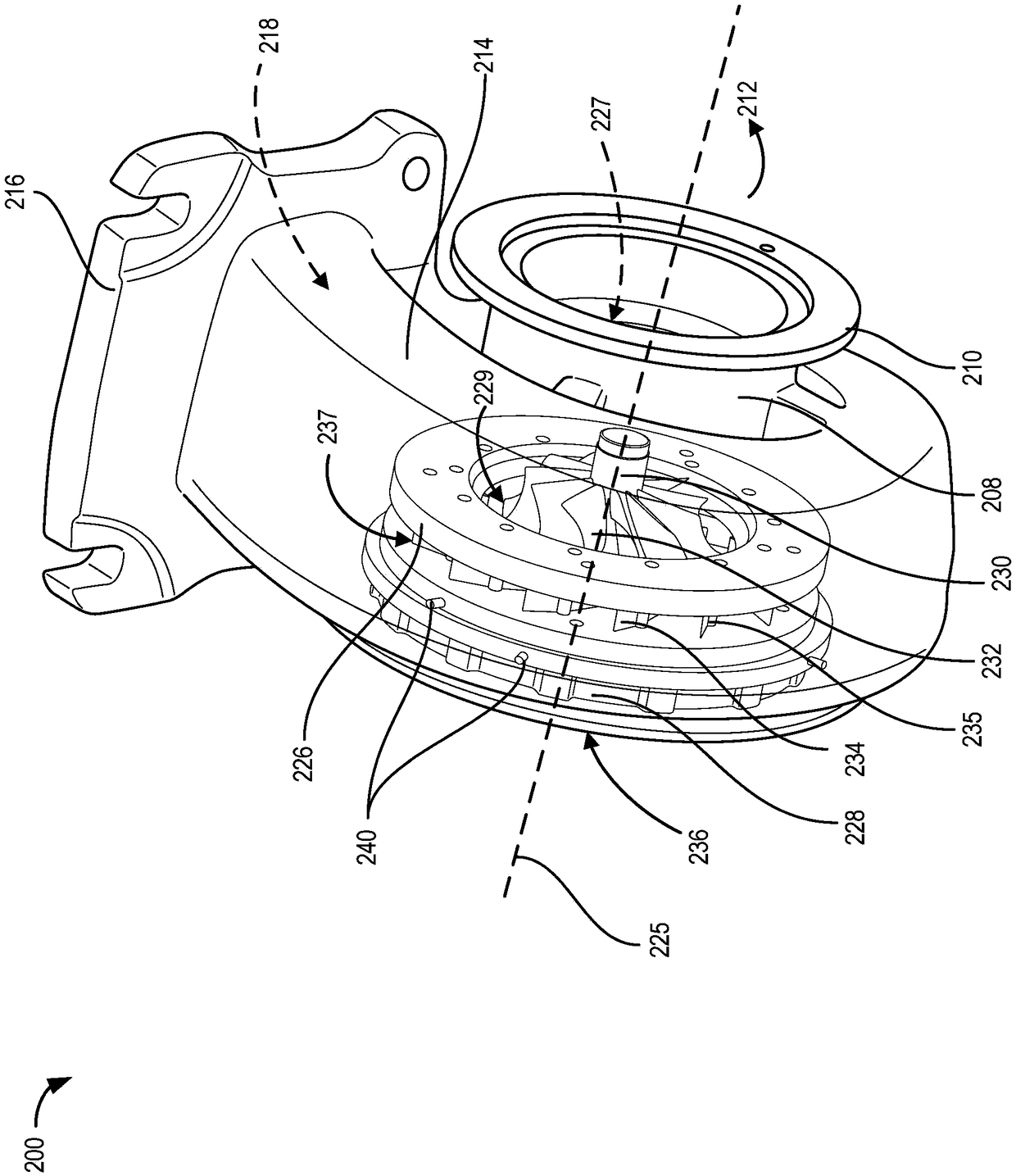

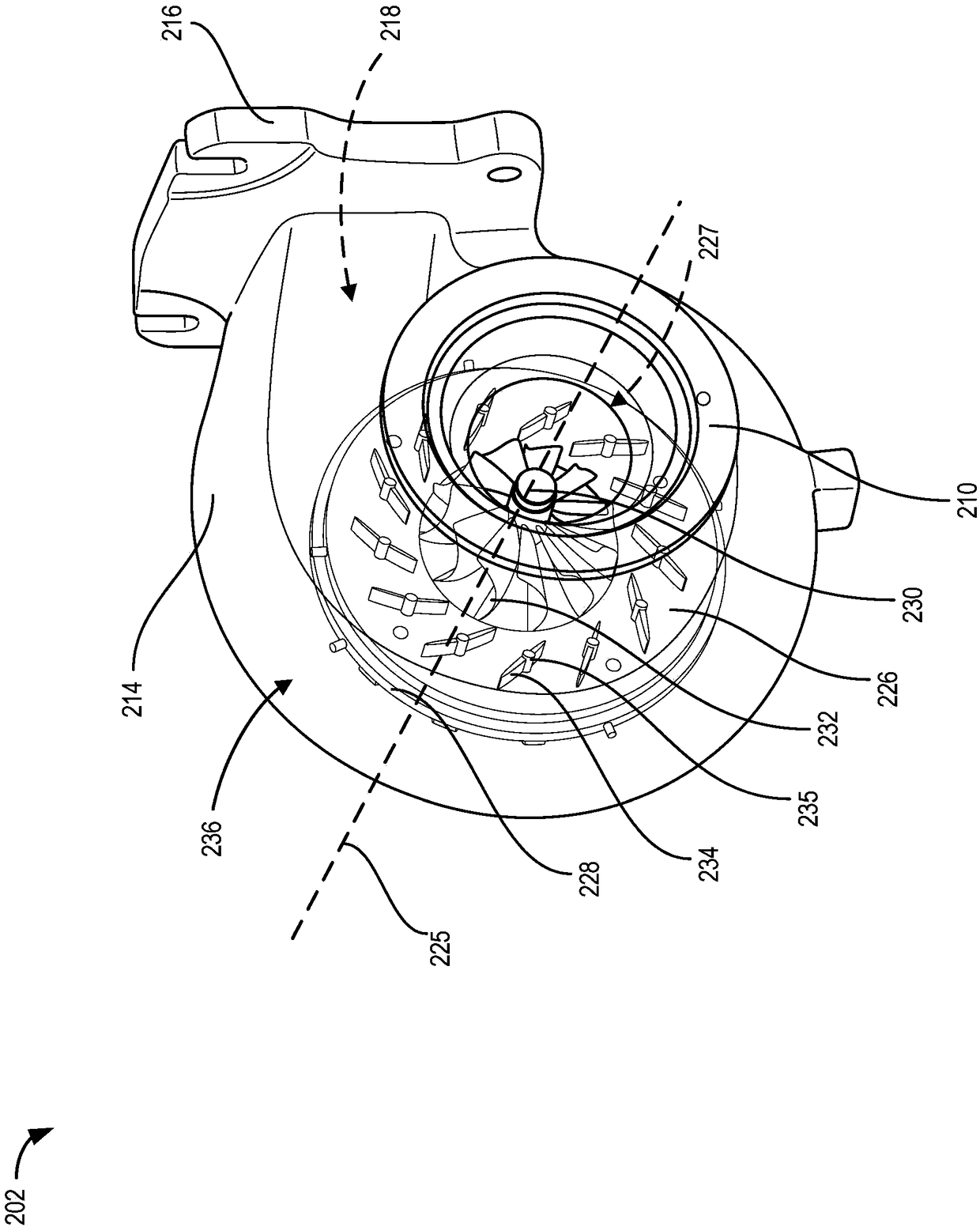

[0031] The following description relates to systems and methods for nozzle vane design of a variable nozzle turbine for a turbocharged engine. Such as figure 1 As shown, the variable nozzle turbine may be an exhaust driven turbine that generates power to operate a compressor coupled to the turbine via a shaft. In this way, the exhaust gas drives the turbine to supply energy to the compressor to boost the pressure and increase the air flow into the engine. Boost pressure may be controlled by a variable turbine rotational speed that is at least partially controlled by flow of exhaust gas through the turbine. Figure 2A to Figure 2B are shown similar to figure 1 A first and a second 3D view of a variable nozzle turbine of the turbine shown. A variable nozzle turbine may include an exhaust passage connected to exhaust outlets on the engine cylinders and a bypass passage directing the exhaust to an exhaust recovery system. Such as Figure 2A As shown, a turbine wheel having a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com