Hydraulic system on-site data acquisition terminal based on pipeline for mining

A technology of hydraulic system and field data, applied in the field of hydraulic equipment, to achieve the effect of high integration and operation automation, improved flexibility, and strong data communication capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

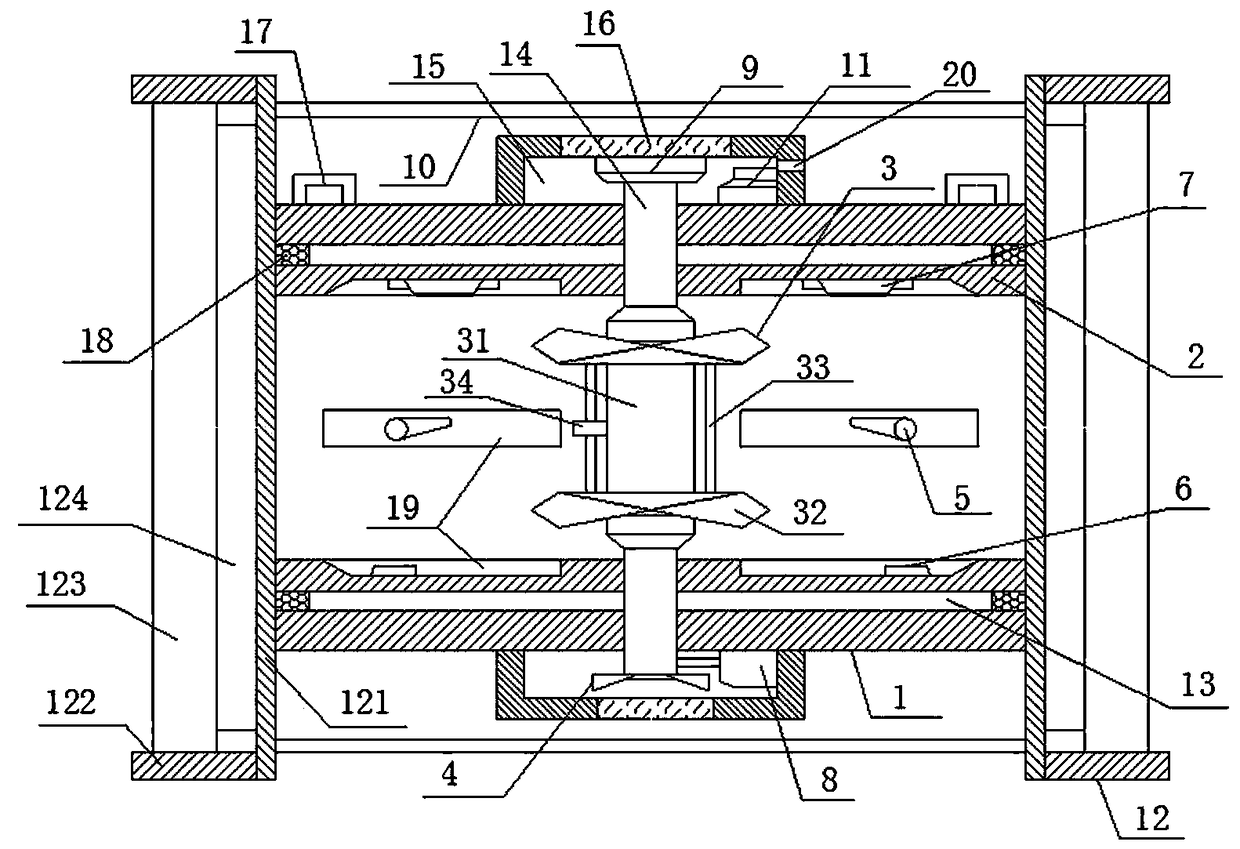

[0016] Such as figure 1 The on-site data acquisition terminal of a pipeline-based mine hydraulic system includes a bearing shell 1, a bearing inner tank 2, a pulsator 3, an indicating impeller 4, an online oil sensor 5, an oil pressure sensor 6, a flow sensor 7, a rotational speed The sensor 8, the brake mechanism 9, the positioning screw 10 and the detection control circuit 11, the bearing shell 1 is a hollow tubular structure with a rectangular axial section, and its front and rear ends are provided with connecting flanges 12, and are located on both sides of the bearing shell 1. The rear end faces of the connecting flange 12 at the end position are connected to each other by at least three positioning screws 10, the axes of the positioning scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com