Y-shaped material supply valve

A technology for supplying valves and materials, which is applied in the direction of lifting valves, valve details, multi-way valves, etc. It can solve the problems of troublesome operation of Y-shaped supply valves, unfavorable noise reduction in the workshop, and too many lower pipes, etc., and achieves simple structure and practicability Strong, low failure rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

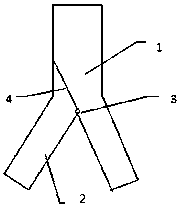

[0033] This embodiment provides a manually controlled Y-type material supply valve, such as figure 1 , the supply valve includes a material inlet pipe and two material outlet pipes, the material inlet pipe and the two material outlet pipes are distributed in an inverted "Y" shape, the material inlet pipe and the material outlet pipe are both rectangular structures, A rotating shaft is provided at the junction of the two material outlet pipes, and a valve plate is arranged on the rotating shaft, and the valve plate is upward, and its height is greater than the width of the material outlet. Among them, the rotating shaft is fixed on the side wall of the junction of the two material outlets through bearings on both sides. The use of bearings to fix the resistance of the valve plate can reduce the resistance when the valve plate rotates, and the top frame of the valve plate is provided with rubber strips for double-sided edging. The valve The sides of the board are riveted with so...

Embodiment 2

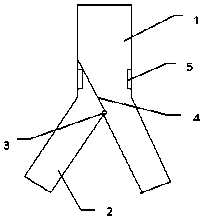

[0035] Same as Embodiment 1, the difference is that this embodiment provides a Y-shaped material supply valve controlled by electromagnetic force, the shaft does not extend out of the side wall of the Y-shaped valve, and electromagnets are arranged on both sides of the material inlet pipe of the Y-shaped valve. , the distribution position of the electromagnet is as figure 2 , located below the top of the valve plate against the material inlet pipe. When it is necessary to change the material outlet of the Y-valve, the solenoid valve on the closed side needs to be energized, and the other side is not energized. The solenoid valve on the closed side is under its magnetic force. Under the action, the valve plate is attracted to this side and the material outlet is blocked, and then the electromagnet is powered off. It should be noted that in order to prevent the electromagnet from magnetizing the valve body and affecting the movement of the valve plate, it is necessary to The va...

Embodiment 3

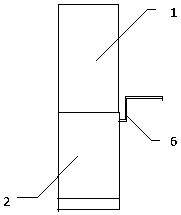

[0037] Same as Embodiment 1, the difference is that this embodiment provides a Y-shaped material supply valve controlled by a cylinder, such as Figure 4 , the rotating shaft extends out of the side wall of the Y-shaped valve, and a connecting rod is fixed outside the side wall. The connecting rod forms a 90° angle with the rotating shaft, and the connecting rod is connected with the telescopic end of the cylinder. To control the opening and closing of the Y-valve material outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com