Remote control automatic gas supply system

A remote control and gas supply system technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of long duration, insufficient automation, complicated process, etc., so as to improve work efficiency and reduce labor Strength, the effect of ensuring the safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

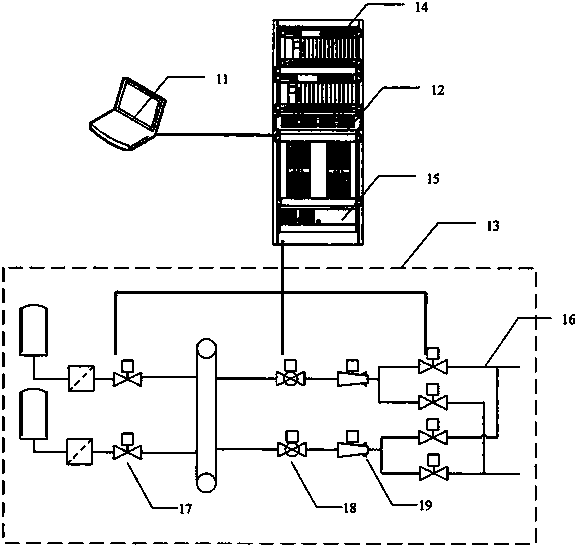

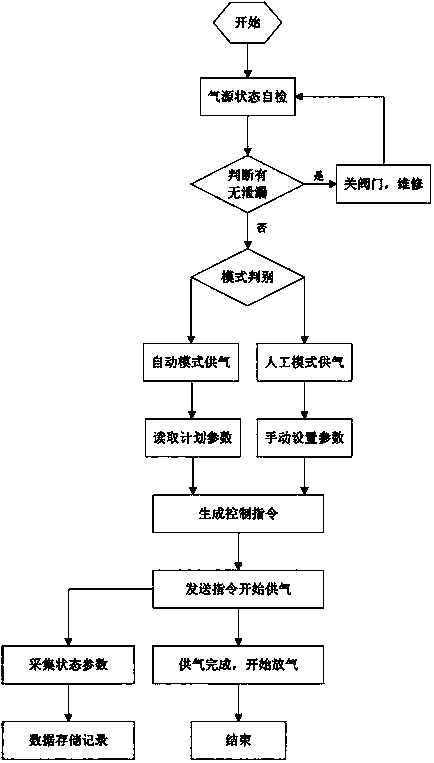

[0015] like figure 1 As shown, the remote control automatic gas supply system developed by the present invention is mainly composed of an industrial control computer 11, a field control system 12, a gas distribution platform system 13, a redundant controller 14, a redundant communication optical fiber network 15, and a gas supply pipeline system 16. Solenoid valve 17, electric ball valve 18, electric pressure reducer 19. The specific connection structure and connection relationship of each part are as follows:

[0016] The industrial control computer 11 is mainly used to write the VxSCADA configuration of Zhejiang University Central Control, establish the automatic workflow model of the gas supply system, and connect to the on-site control system through a redundant optical fiber communication network to realize remote control of gas supply, remote control of gas release, Automatic switching and unattended functions.

[0017] The on-site control system 12 is mainly controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com