Anti-explosion container breakover device and method

A technology of conduction device and container, which is applied in the experimental field of explosive performance parameters, can solve the problems of easy aging of insulating rubber, low experimental efficiency, short circuit, etc., achieve convenient replacement of wearing parts, excellent anti-knock performance, and solve aging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

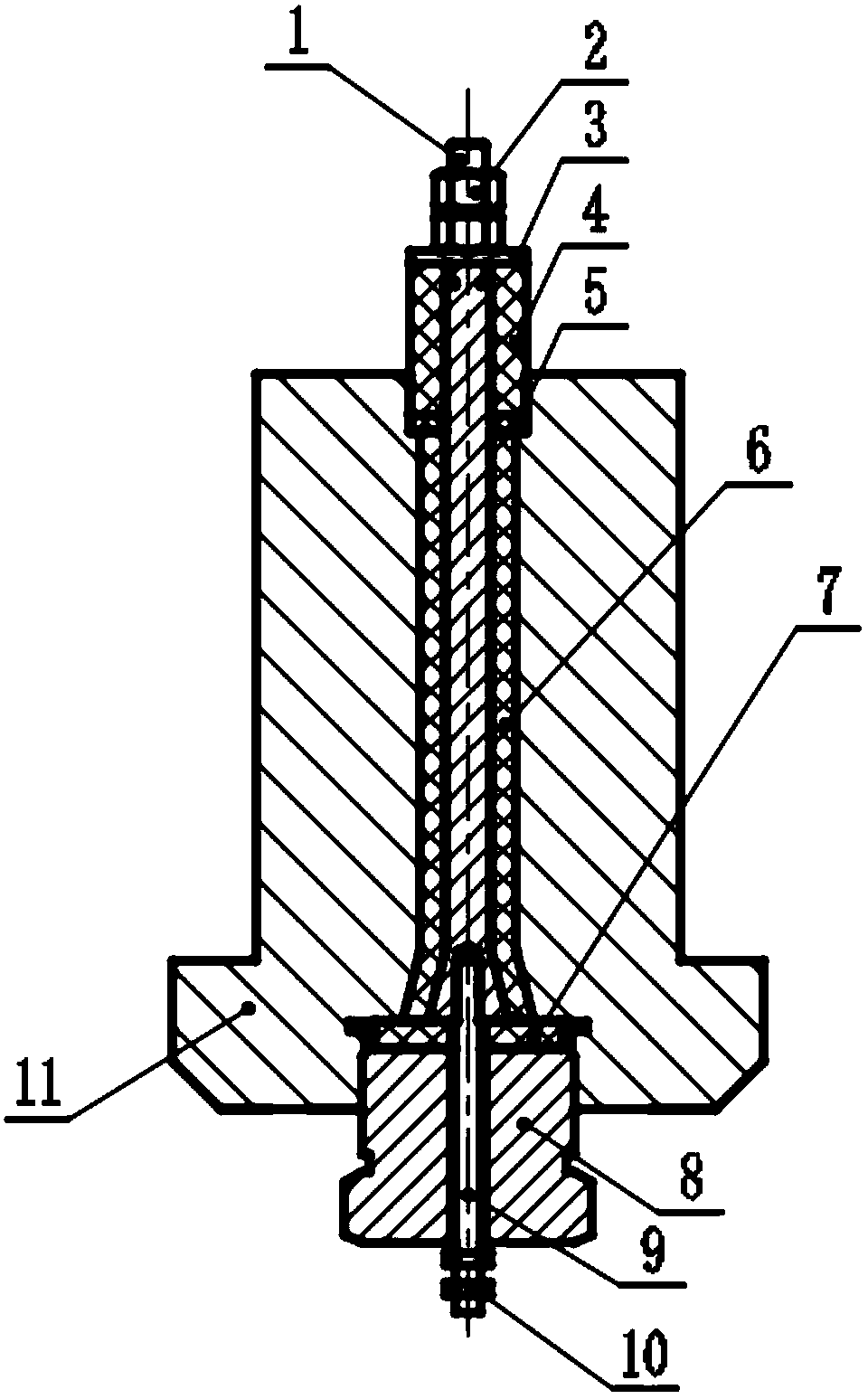

[0022] In this embodiment, a set of research equipment for the electrostatic sensitivity of explosives inside the anti-explosion container is designed, focusing on the design of the tip discharge terminal.

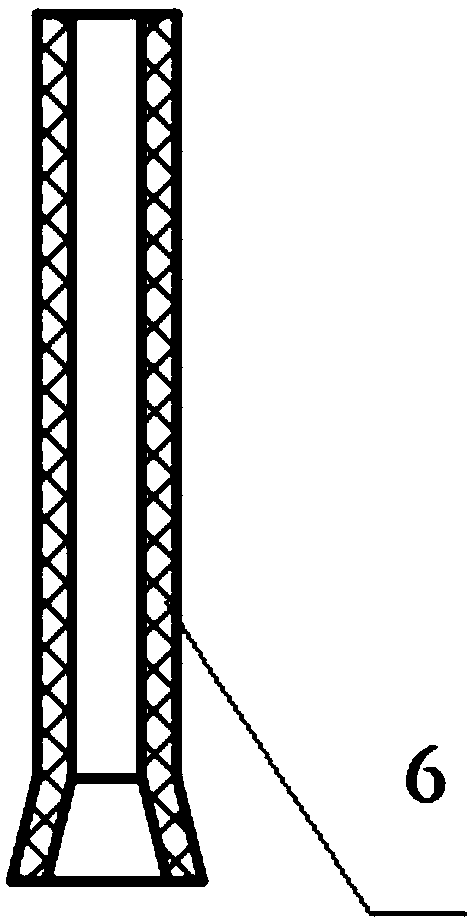

[0023] The anti-explosion container internal explosive electrostatic sensitivity research device is mainly composed of an anti-explosion container, an anti-explosion container conduction device, an external capacitor, and a sharp discharge terminal. The anti-explosion container conduction device includes a copper external terminal 1, a nut A2 , fixed gasket 3, outer insulating sleeve 4, insulating gasket A5, inner insulating sleeve 6, insulating gasket B7, flameproof screw 8, inner terminal post 9, nut B10 and container wall 11, the diameter of the outer terminal post 1 4mm, the upper end of the external terminal 1 is provided with threads, the external terminal 1 is fixed on the outer insulating sleeve 4 through threads, and the external terminal 1 runs through the externa...

Embodiment 2

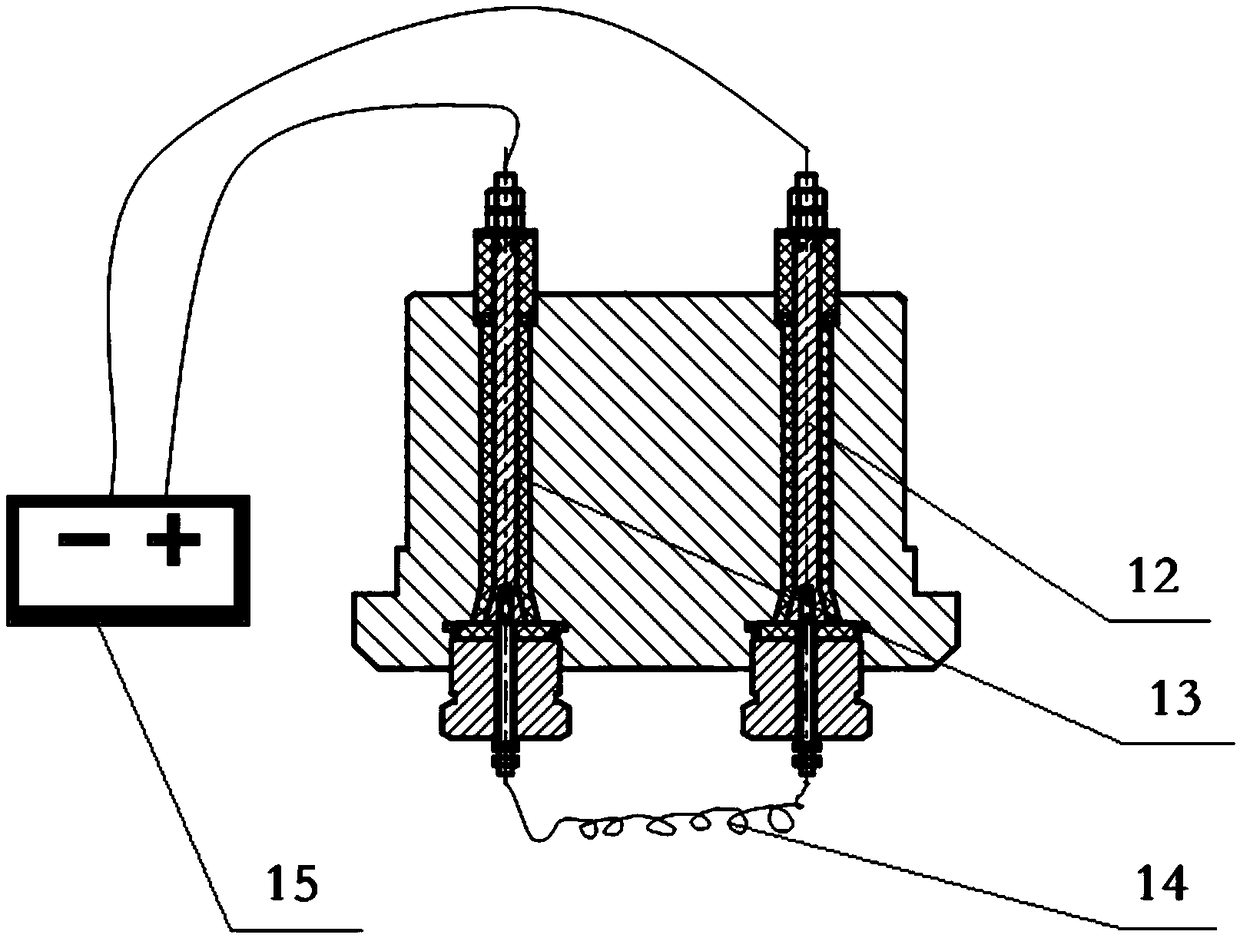

[0031] In this embodiment, an experimental device for thermal ignition of explosives in an anti-explosion container is designed, and the method of using the conduction device in series is mainly explained.

[0032] The thermal ignition experiment device of the explosive in the anti-explosion container is mainly composed of an anti-riot container, a conduction device A12, a conduction device B13, a power supply 15, and a heating wire 14. The anti-riot container is designed to have an upper end opening, a wall thickness of 50 mm, and an inner diameter of 200 mm. , a hollow cylinder structure with a depth of 200mm, the conduction device A12 and the conduction device B13 are installed side by side on the container wall, and the specifications of each component are consistent with the embodiment 1. In actual use, the two poles of the power supply are respectively connected to the conduction device A12 and the conduction device B13. The external terminal 1 of the conduction device B13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com