High temperature platinum resistor assembling method

An assembly method and platinum resistance technology, applied in the direction of using electrical devices, thermometers, measuring devices, etc., can solve the problems of unstable measurement accuracy and weak connection, and achieve the effect of durable measurement accuracy and good connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

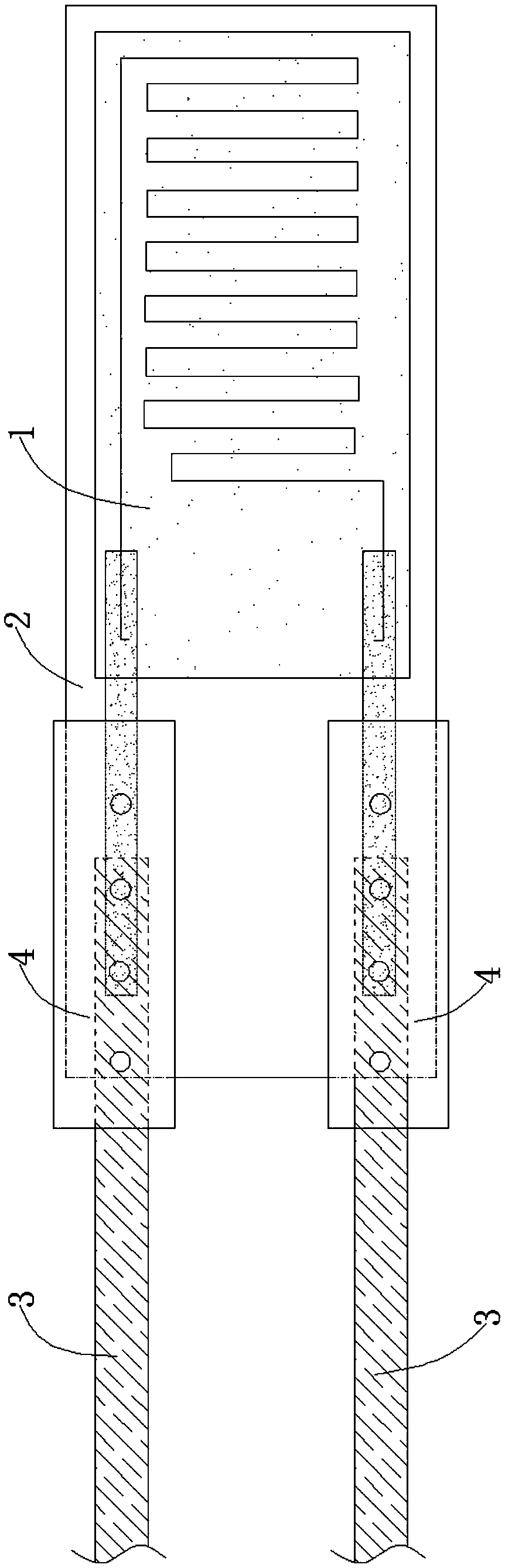

[0024] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

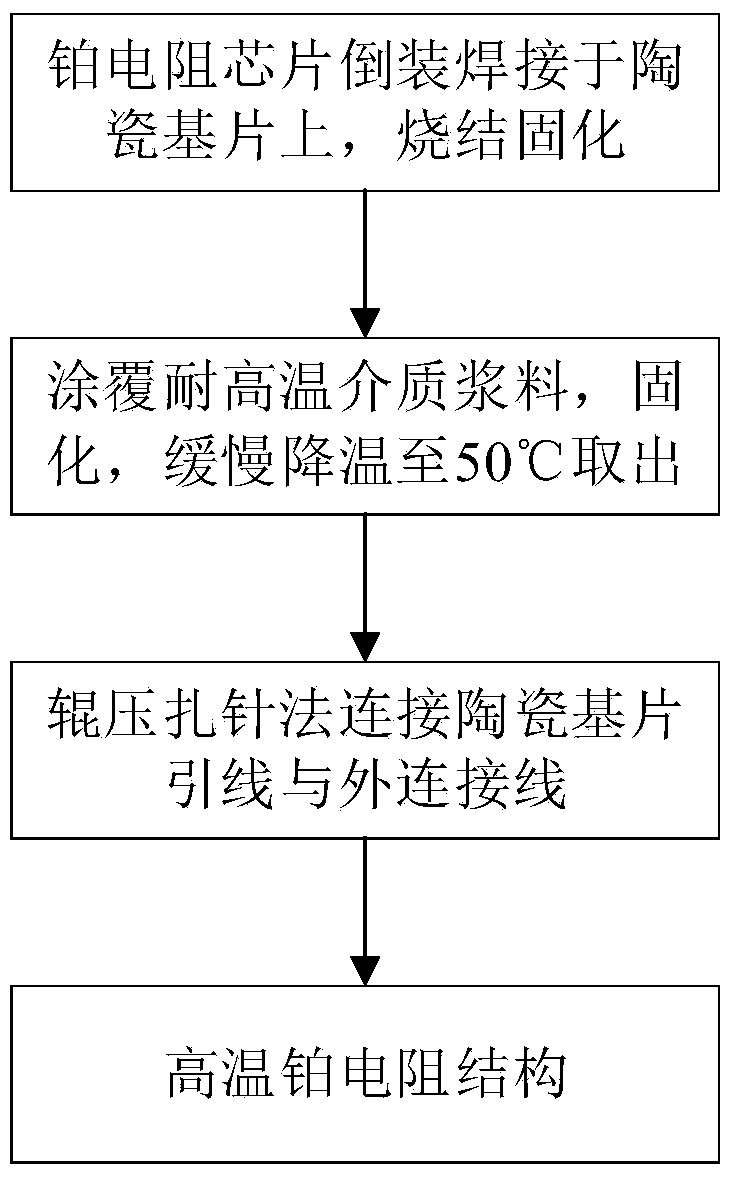

[0025] Such as figure 1 As shown, a high-temperature platinum resistor assembly method, the specific steps are as follows:

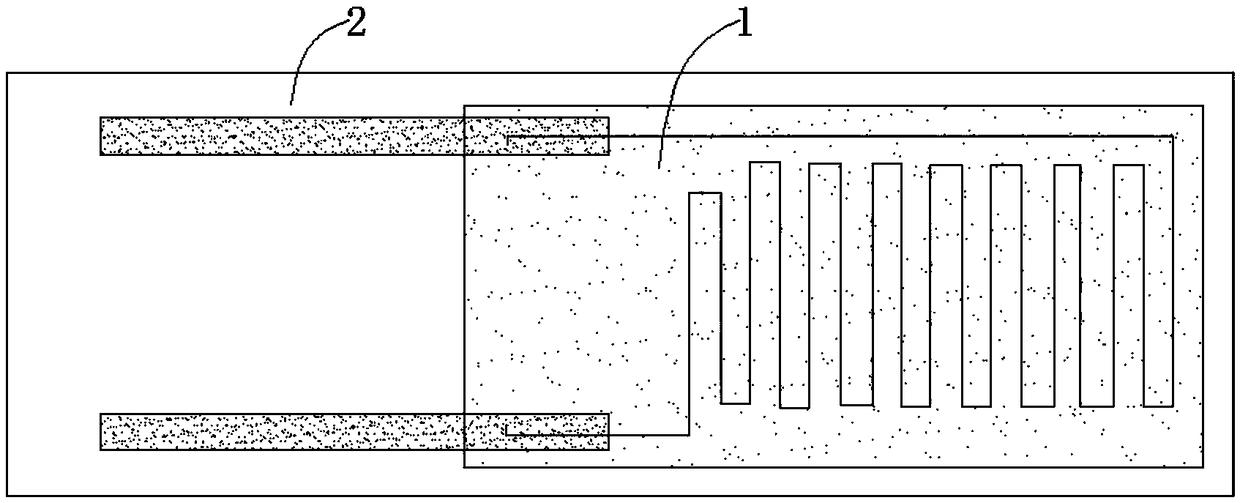

[0026] Step 1: Use platinum paste to flip-chip-bond the platinum resistance chip 1 on the ceramic substrate 2 (flip-chip bonding is a conventional technique in this field, and will not be described in detail here), and put it into a high-temperature furnace with a temperature of 800-900°C Sintering and solidification inside the sintering solidification, and nitrogen gas is filled for protection during sintering and solidification (of course, the protection gas can also be other inert gases of the same family), and the semi-finished product after sintering and solidification for 1 hour is as follows: figure 2 As shown, the product is then cooled to ambient temperature through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com