A graphical display method for laser processing site

A graphics display and laser processing technology, which is applied in laser welding equipment, metal processing equipment, graphics and image conversion, etc., can solve the problems of increasing the utilization rate of workpiece waste, checking the details of the workpiece, and not being able to display the workpiece well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

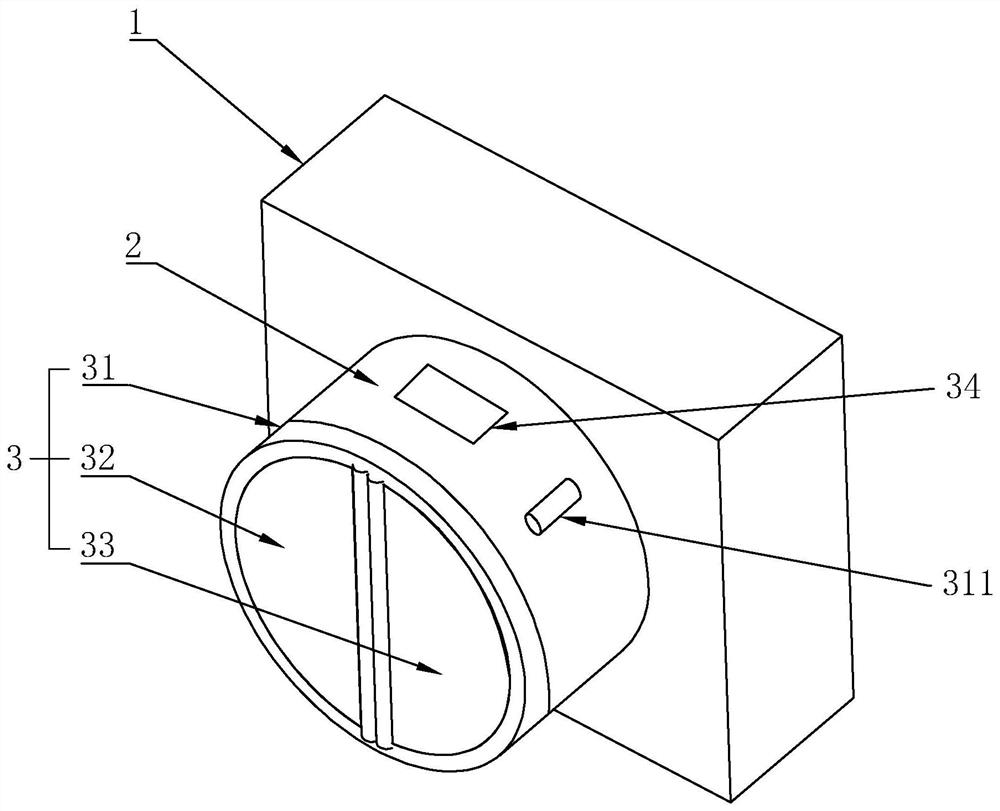

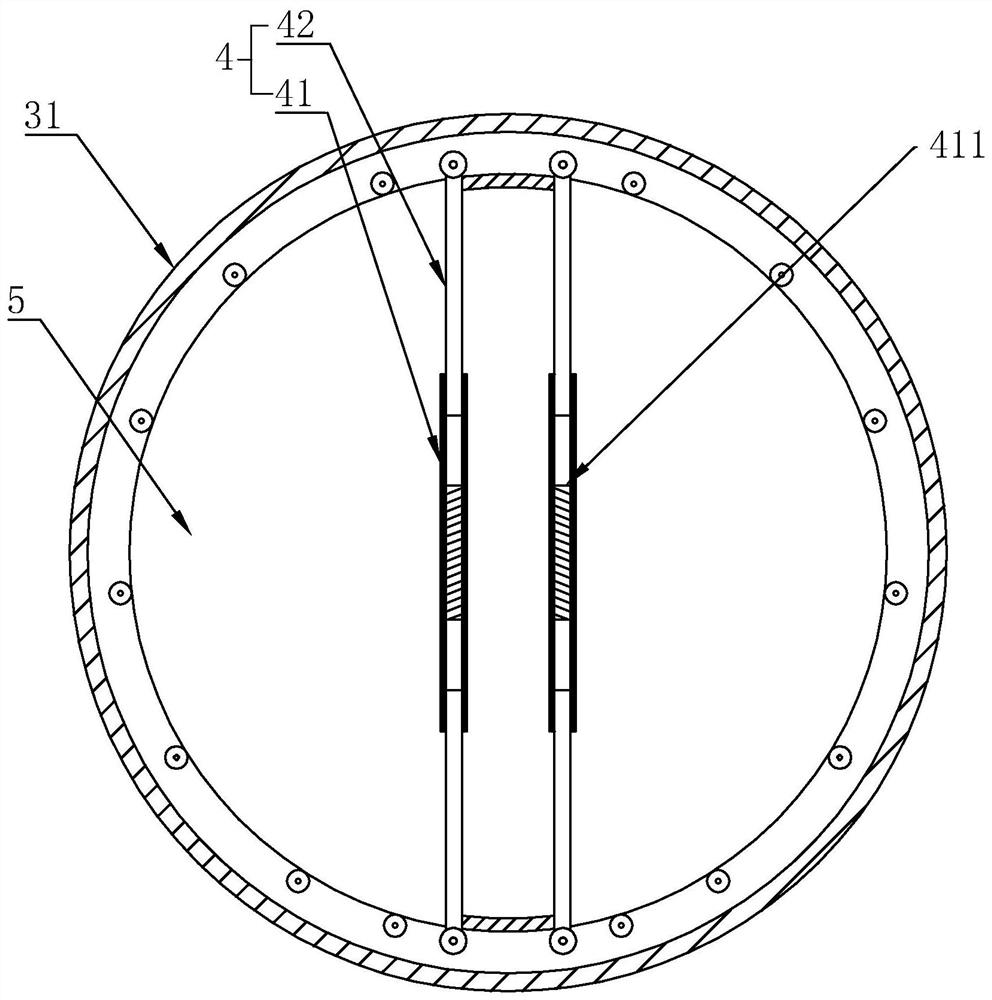

[0016] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

[0017] refer to Figures 1 to 2 As shown, a method for displaying graphics on the spot of laser processing in this embodiment includes the following steps:

[0018] Step 1, use the drawing software to draw a workpiece graphic that is 1 to 1 with the workpiece, and store the workpiece graphic in the nesting software;

[0019] Step 2, using SmartManager to add a processing engine for processing graphics on the operation interface of the nesting software, and input the workpiece graphics into the processing engine, and the processing of the processing engine enables the workpiece graphics to be scaled and rotated;

[0020] Step 3: Input the processed workpiece graphics into the nesting software, and display it through the display interface of the nesting software, and set up an input device to interact with the staff to communicate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com