Novel corn no-tillage seeding device for split application of seed fertilizer

A no-tillage sowing and corn technology, applied in the direction of fertilizer and sowing equipment, shovel, plow, etc., can solve the problems of excessive soil disturbance, mixed grass and soil, etc., and achieve the effect of reducing disturbance, small disturbance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Provide specific embodiments below in conjunction with accompanying drawings.

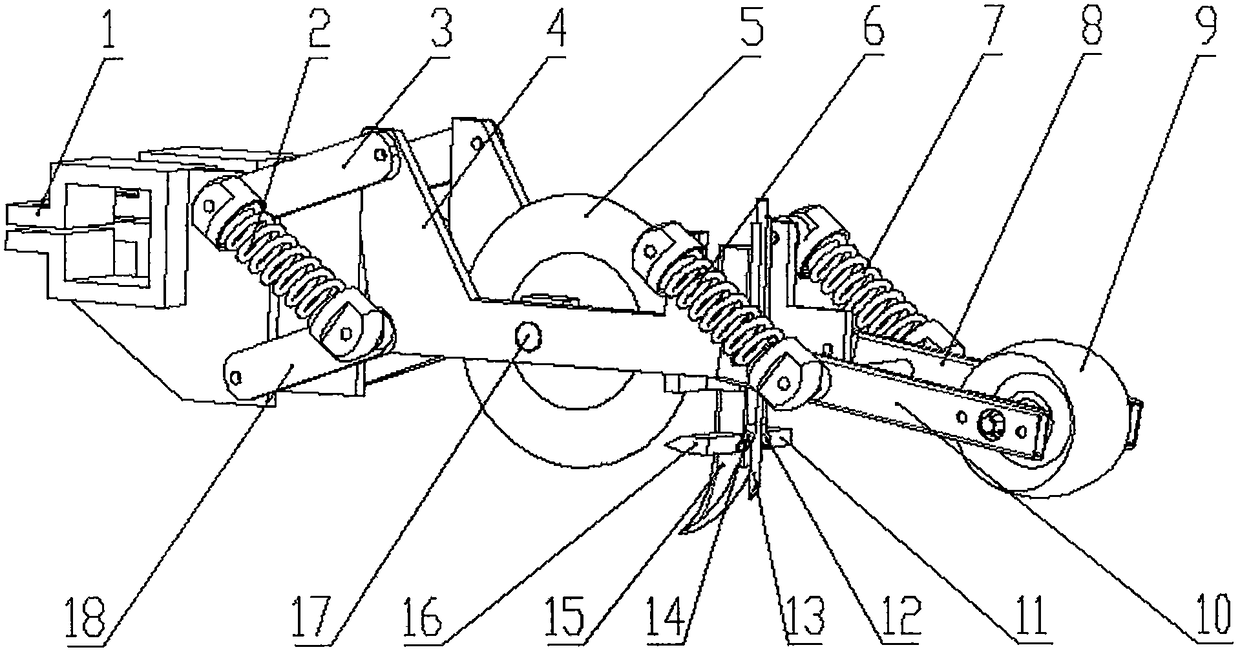

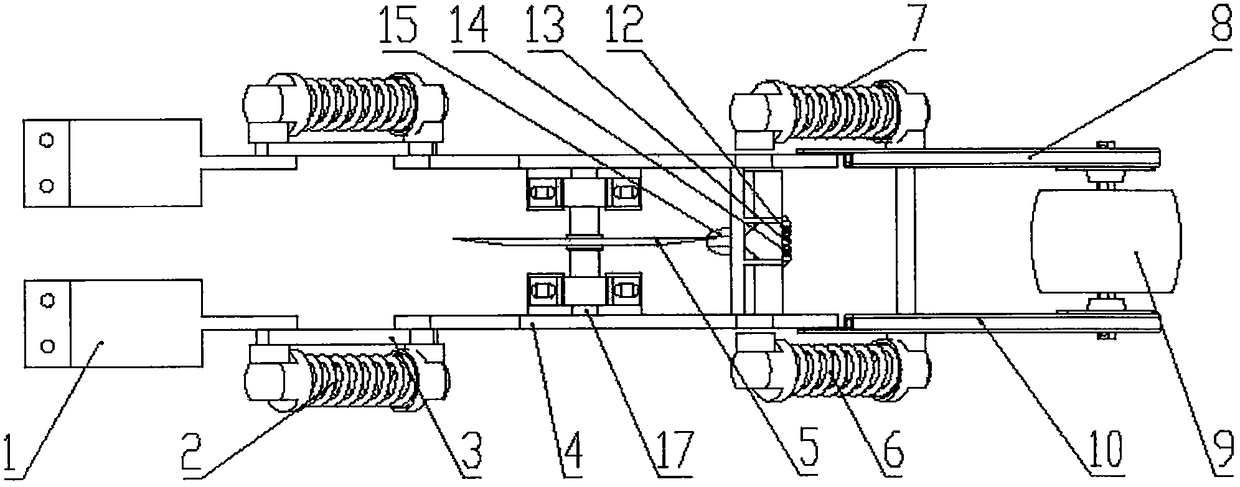

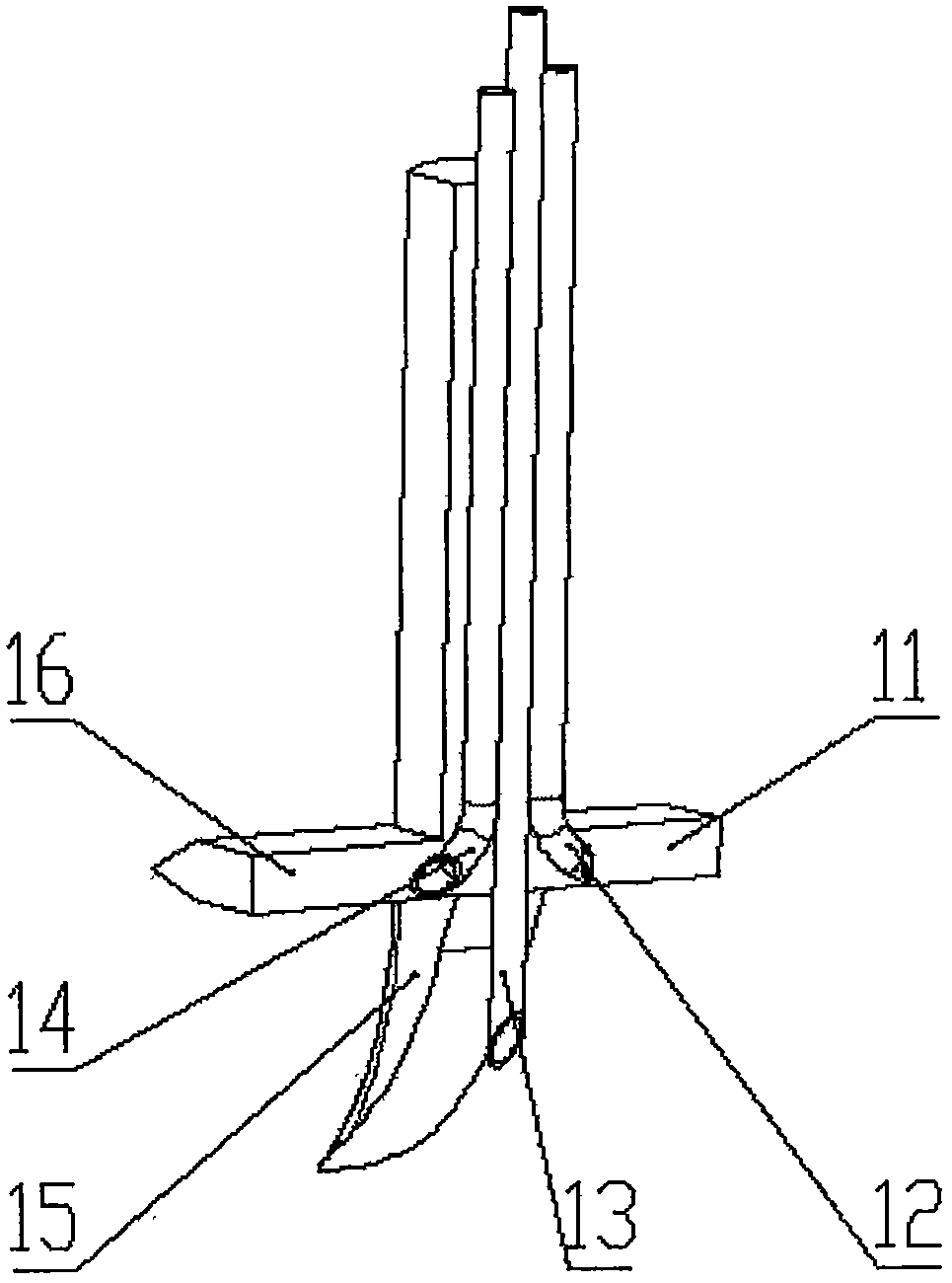

[0024] One embodiment of the present invention is to integrate stubble breaking, ditching, fertilization, sowing, and suppression operations in one operation in arid and semi-arid areas, specifically as figure 1 , figure 2 shown. Driven by the power machine, the planter starts to work, and the disc cutter 5 breaks stubble under the action of the frame's own pressure, ground friction and power machine tension, chops straw and root stubble, and pushes the straw and weeds to both sides of the disc. Fertilization and ditching horizontal knife 11, hoe shovel type ditching device 15, sowing ditching horizontal knife 16 on disc cutter 5 rear sides start working, respectively leave base fertilizer ditch, kind of fertilizer ditch, kind of ditch in soil lower layer; , While ditching, the sowing and fertilizing device also starts to work, and the seeds, seed fertilizer, and base fertilizer are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com