Automatic horizontal flaring machine for passenger car steel wheel rims

A technology for passenger cars and flaring machines, which is applied to rims, vehicle parts, feeding devices, etc., can solve the problems of inability to effectively improve flaring efficiency, inflexible device structure, and reduce labor intensity of workers, etc. The effect of sliding flexibility and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

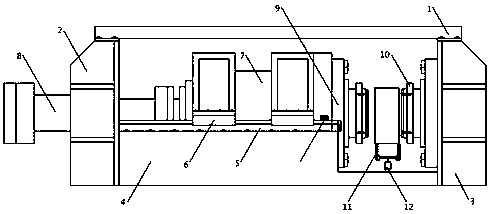

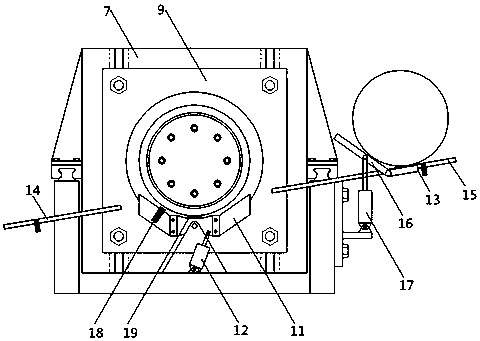

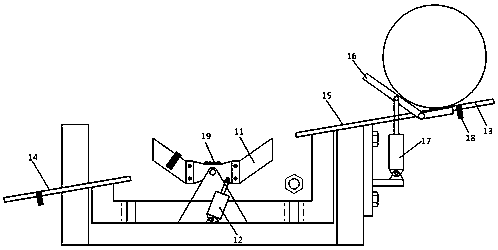

[0024] see Figure 1-Figure 2 , an automatic horizontal flaring machine for steel wheel rims of passenger cars, comprising a body composed of a beam 1, a left stand 2, a right stand 3 and a base 4, a linear guide rail 5 is arranged above the base 4, and the A linear bearing 6 and a displacement sensor 20 are arranged on the linear guide rail 5, and a slider 7 that uses the linear bearing 6 to slide laterally on the linear guide rail 5 is arranged on the linear bearing 6. A hydraulic pressure sensor is fixed on the outside of the left stand 2 Oil cylinder 8, the piston rod of described hydraulic oil cylinder 8 passes through left stand 2 and is fixedly connected with slide block 7, and the right side of described slide block 7 and the left end face of right stand 3 are equipped with mold support 9, and described mold A rim flaring die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com