Intelligent management control method and system for on-site welding construction process

An intelligent management system and on-site welding technology, applied in manufacturing computing systems, welding equipment, auxiliary welding equipment, etc., can solve problems such as unfavorable popularization and use, and concentration of on-site welding construction resources, so as to reduce the difficulty of programming and avoid programming errors. , the effect of reducing qualification requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

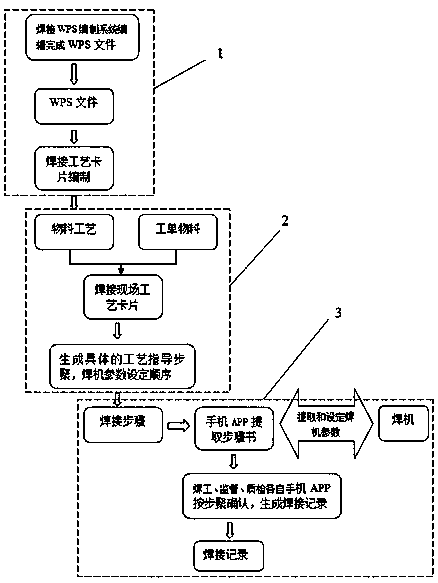

[0033] by attaching figure 1 and 2 It can be seen that the present invention relates to an on-site welding construction process management and control system, including welding equipment, a welding equipment on-site operation platform is provided next to the welding equipment, and a management control computer is installed in the management control room. , the management control computer communicates with the on-site operation platform and management control operation terminal through the network system, and the on-site operation personnel realize human-computer interaction with the on-site operation management and control personnel through the on-site operation operation platform and control computer system.

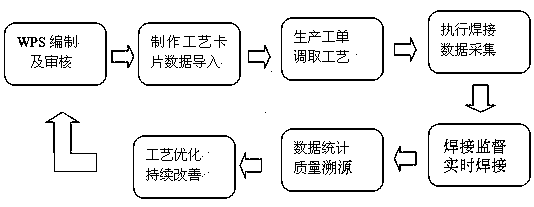

[0034] The whole process of on-site welding construction is divided into four parts, the first part is the establishment of the database, the second part is the preparation of the on-site operation process and work instructions, the third part is the actual operation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com