Motor bracket riveting machine

A motor bracket and riveting machine technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as dislocation of semi-finished bracket riveting stations, machine shutdown, defective motor brackets, etc., to improve accuracy degree, the effect of good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

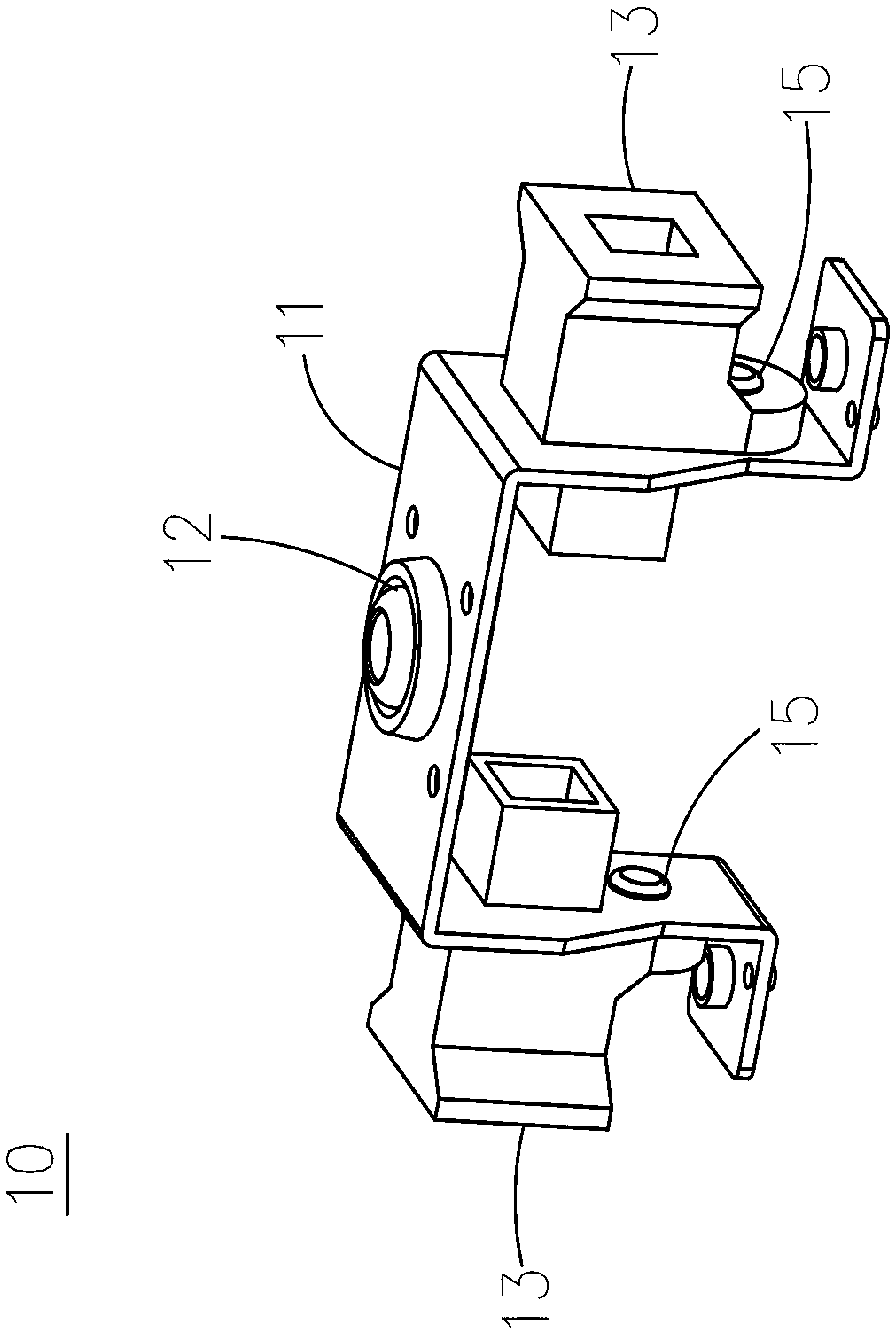

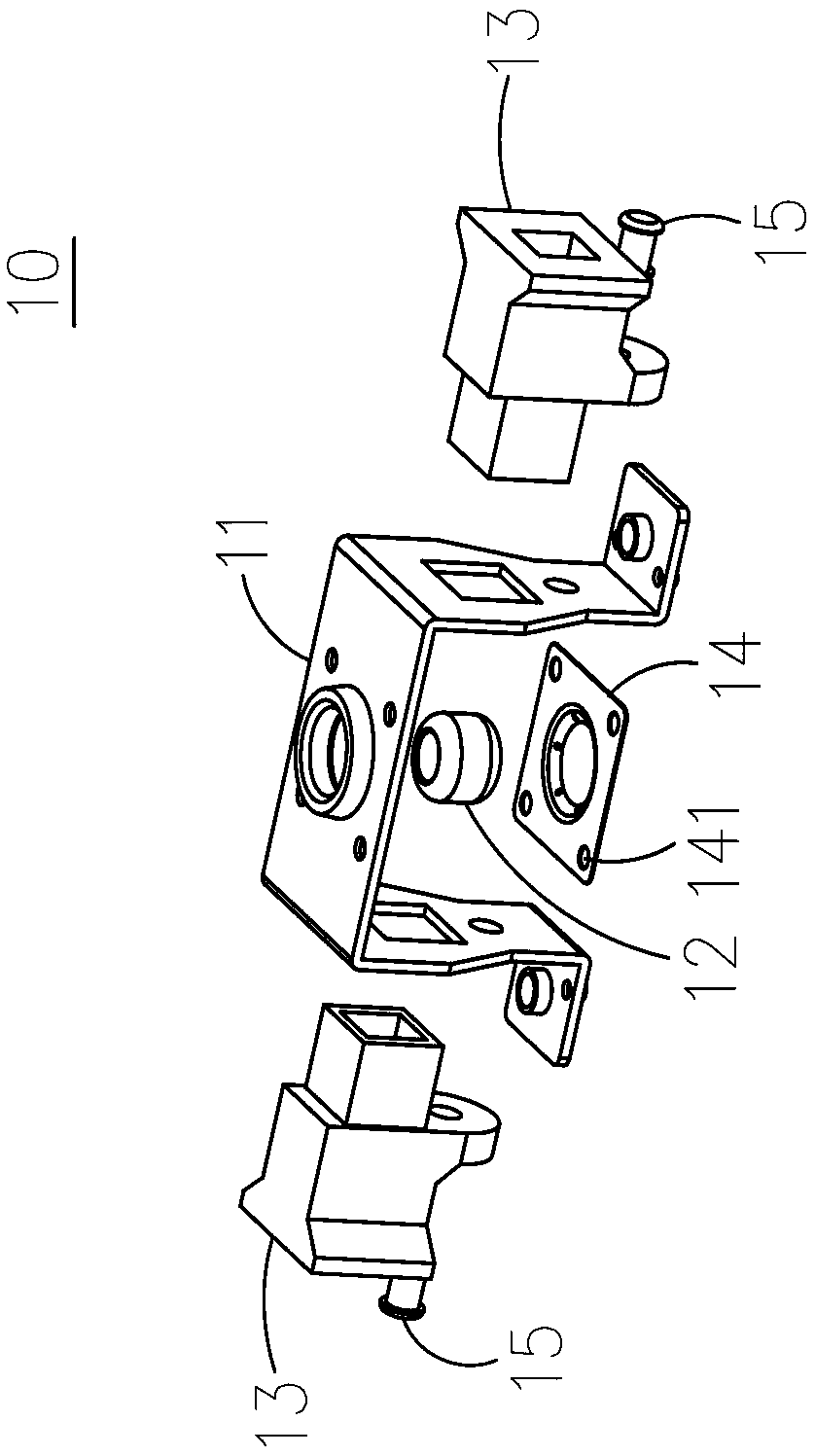

[0053] see figure 1 , 2 , the motor bracket 10 includes a bracket part 11, on which a bearing 12 and a carbon brush box 13 are integrated, the bearing 12 is installed on the bracket part 11 by riveting the shrapnel 14 and the bracket part 11, and the carbon brush box 13 is installed on the bracket part 11 through Rivets 15 are riveted on the support member 11 .

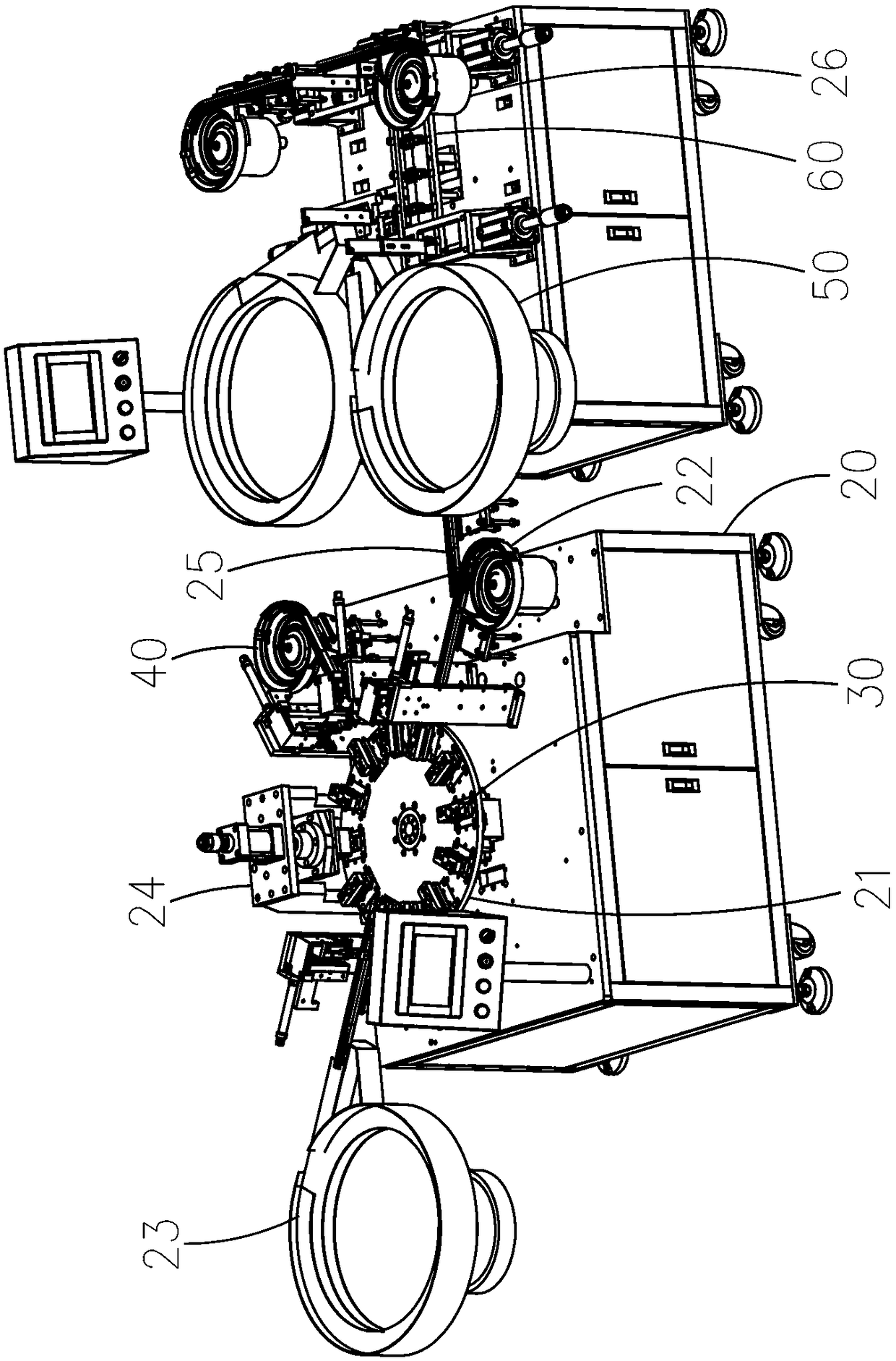

[0054] The motor bracket riveting machine of the present invention is used to complete the placement of the shrapnel 14, the placement of the bearing 12, the placement of the bracket 11, the riveting of the shrapnel 14 and the bracket 11, the insertion of the carbon brush box 13, and the riveting of the rivet 15 The automation equipment of the process can realize the automatic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com