Shot blasting machining equipment for clutch connecting disc

A technology of processing equipment and connecting plate, applied in metal processing equipment, solid separation, manufacturing tools, etc., can solve the problem that steel shot cannot be effectively screened, and achieve the effect of facilitating centralized collection, ensuring processing quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

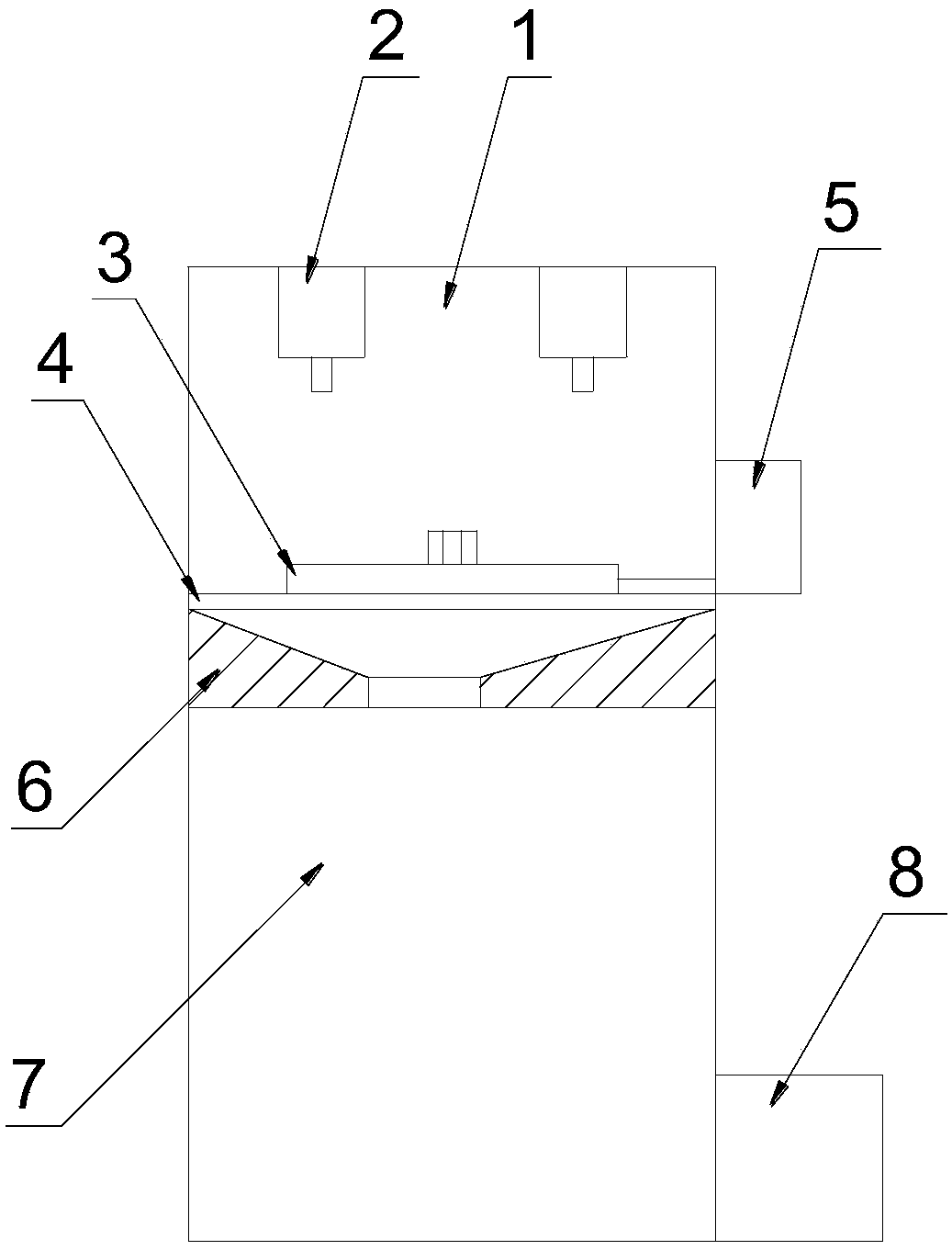

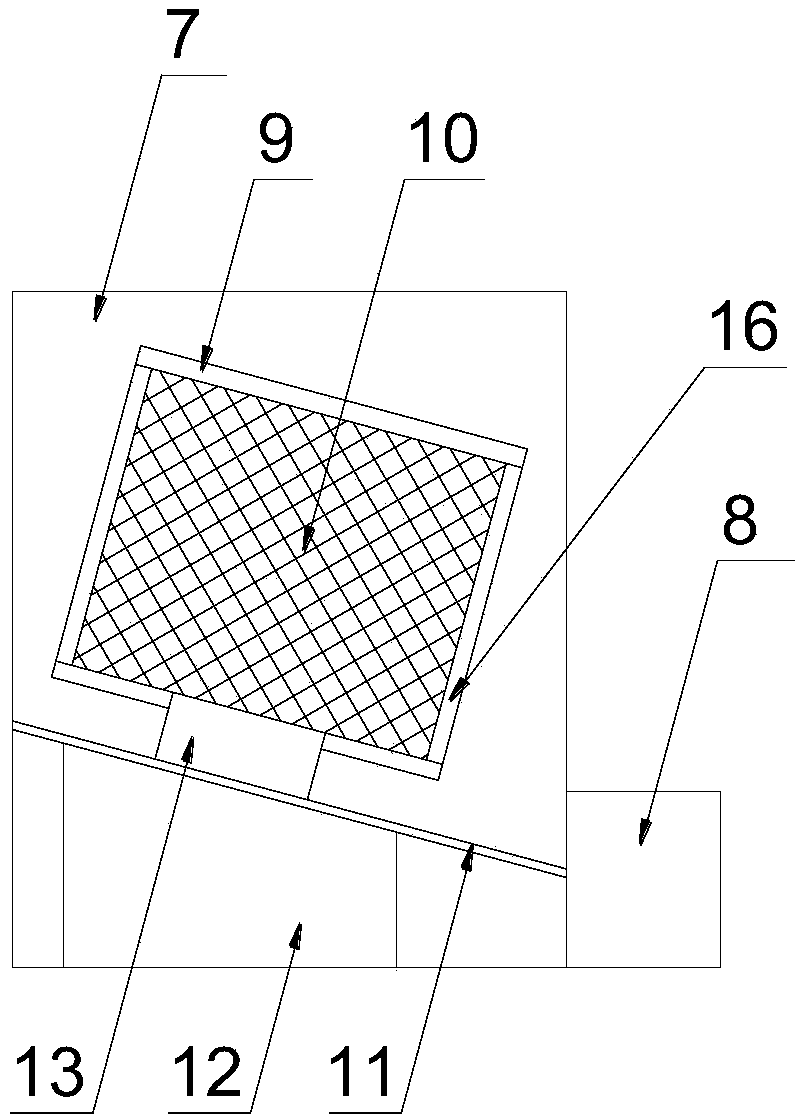

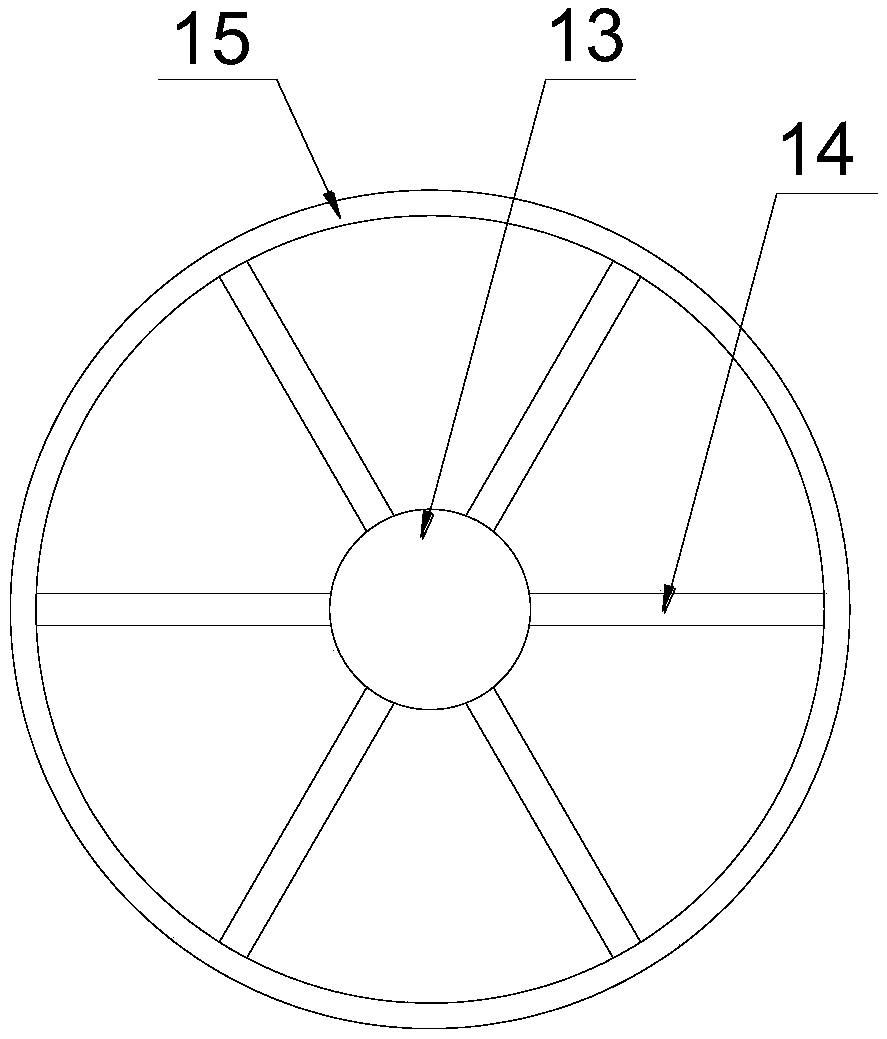

[0019] like Figure 1-3 as shown, figure 1 It is a structural schematic diagram of the shot blasting processing equipment for the clutch connecting disc proposed by the present invention; figure 2 It is a schematic diagram of the internal structure of the filter chamber in the shot blasting processing equipment for the clutch connecting plate proposed by the present invention; image 3 It is a partial structural schematic diagram of the filter assembly in the shot blasting processing equipment for the clutch connecting disc proposed by the present invention.

[0020] refer to Figure 1-3 , a shot blasting processing equipment for a clutch connecting disc proposed by the present invention, including a processing bin 1, a shot blasting device 2, a mounting frame 4, a turntable 3, a first driving device 5, a guide plate 6, a recovery box 8 and a filter bin 7 , and the filter assembly 9, the second driving device 12 and the partition 11 that are arranged in the recovery bin 7;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com