Vertical concrete mixer and concrete production line

A concrete mixer, vertical technology, applied in the field of vertical concrete mixer and concrete production line, can solve the problems of high temperature, affecting the internal environment temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

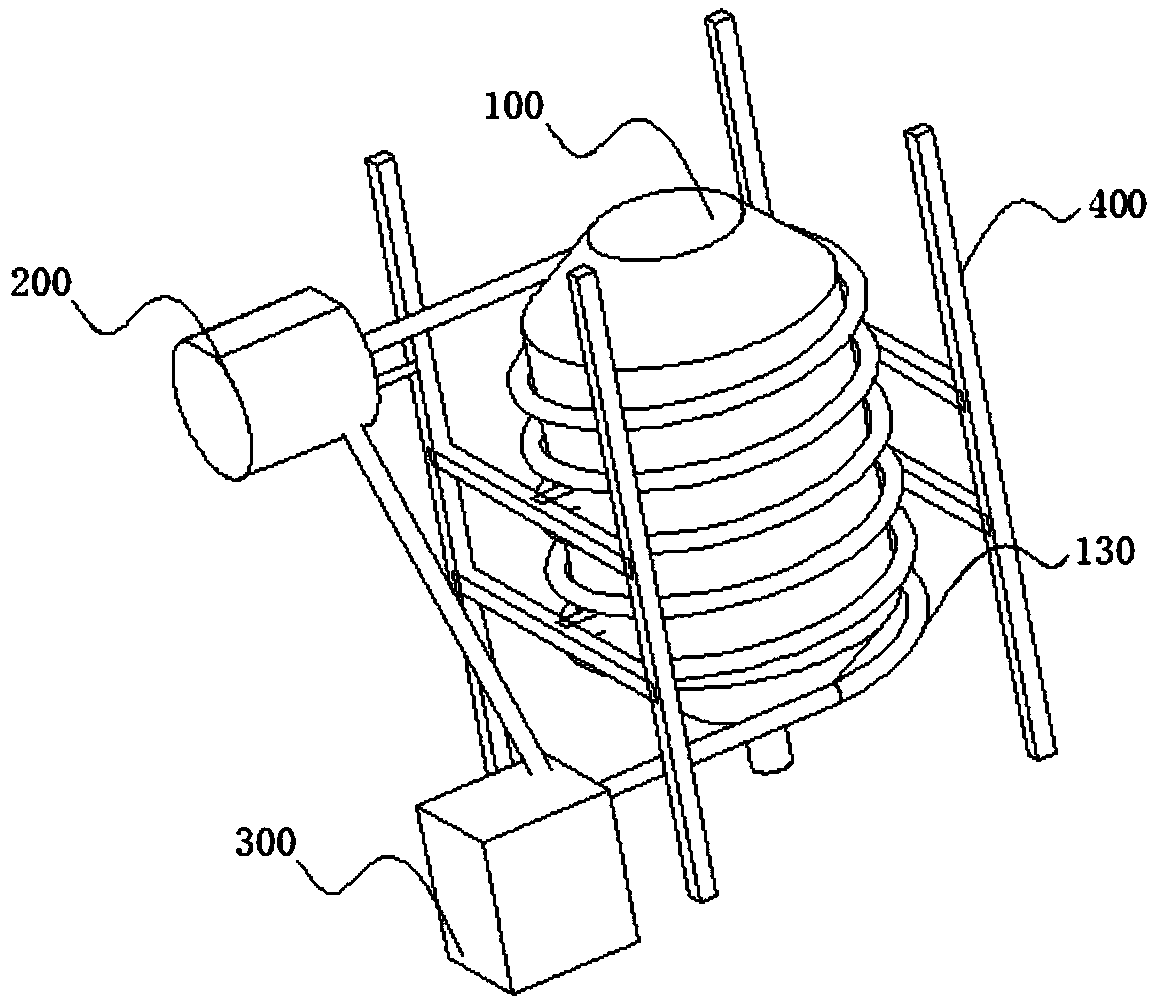

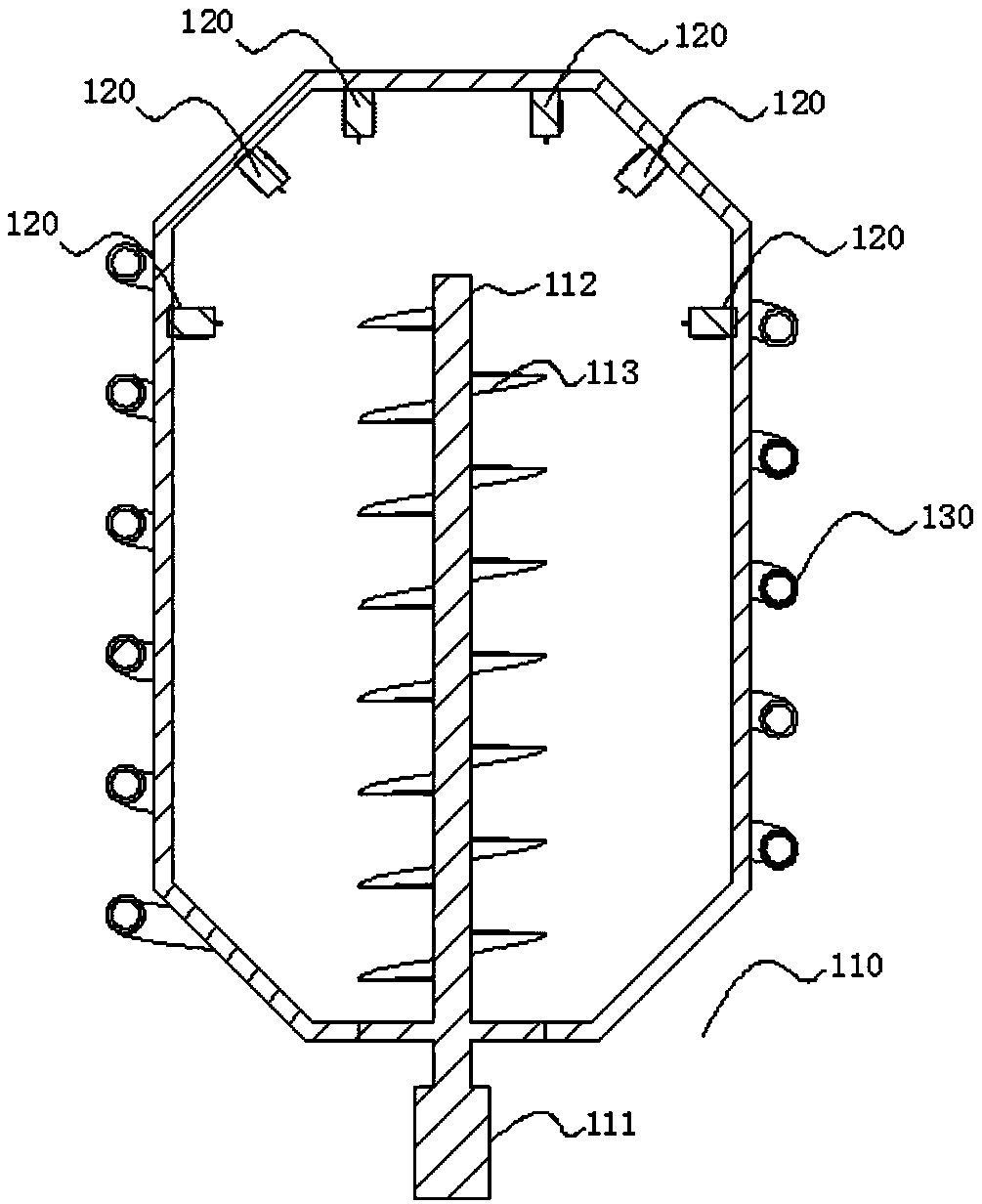

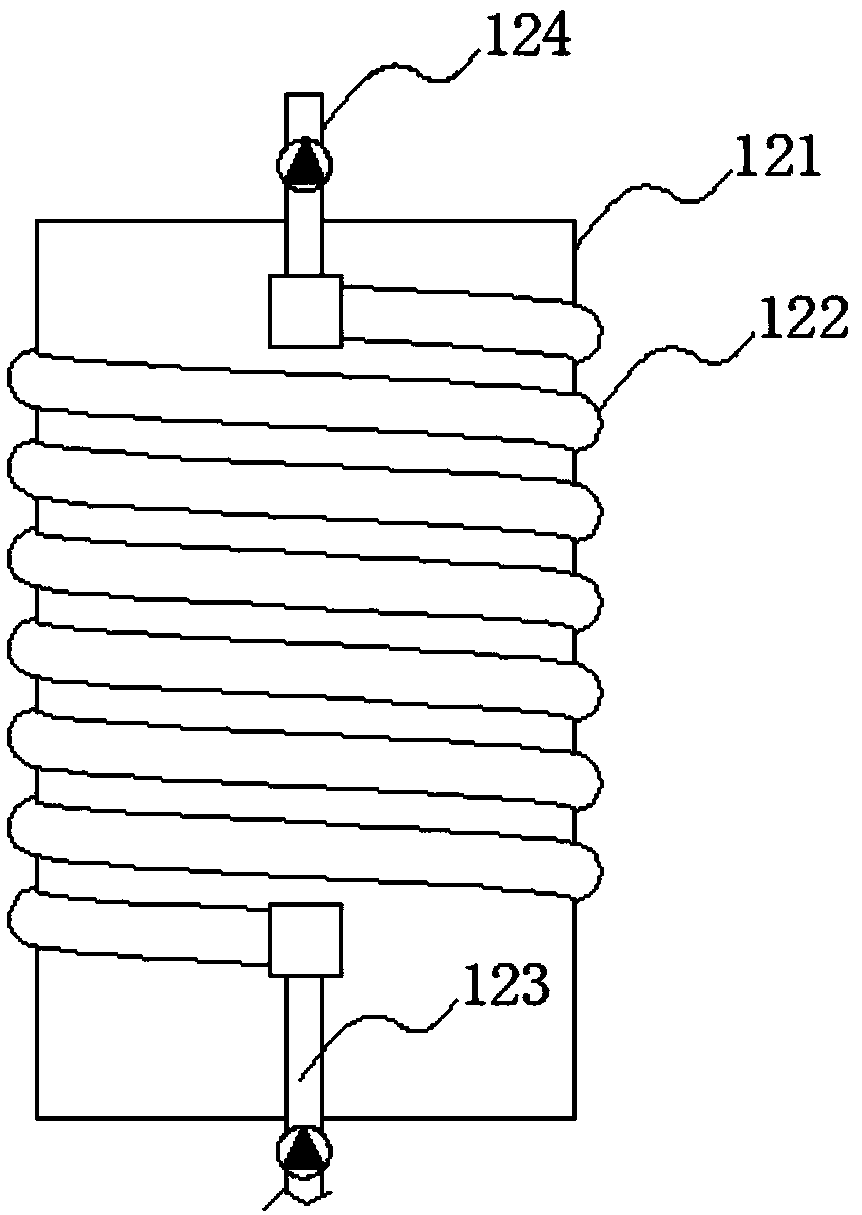

[0048] Such as Figure 1-6 As shown, the vertical concrete mixer provided in this embodiment includes: a mixing drum, a mixing assembly 110, a cooling channel 130 and a frame 400; the mixing drum 100 is fixedly installed on the frame 400, and the mixing drum 100 A mixing assembly 110 is installed on it and is provided with a material inlet and a material outlet. The mixing assembly 110 extends into the inside of the mixing drum 100 and can stir the concrete; the cooling channel 130 is wound on the outer wall of the mixing drum 100 for To cool down the working mixing drum 100, the water inlet end of the cooling channel 130 is connected to the water tank 200, and the water outlet end is connected to the refrigerator 300, and the refrigerator 300 communicates with the water tank 200 to form a cooling cycle.

[0049] After the mixer is in operation, the temperature of the outer surface is relatively high, so the water in the water tank 200 is passed into the cooling channel 130. S...

Embodiment 2

[0062] On the basis of Embodiment 1, this embodiment provides a concrete production line, including a material weighing device, a material conveying device, a material storage device and the above-mentioned vertical concrete mixer; the material weighing device is used for sand and gravel Weighing, the material conveying device is used to transport the weighed sand and gravel to the vertical concrete mixer for mixing, and the material storage device is used to store the stirred concrete. This line includes vertical concrete mixers, so it has all the advantages of vertical concrete mixers.

[0063] Concrete production line is a production line composed of vertical concrete mixer, material weighing system, material conveying system, material storage system and other auxiliary facilities. Lime, cinder and other raw materials are mixed and stirred, and finally made into concrete, which is put into construction and production as materials.

[0064] Among them, the concrete producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com