Phosphatization method for quenched steel plate production line for laboratory simulation of vehicles

A laboratory simulation and automobile technology, which is applied in the field of phosphating of quenched steel plate production line for laboratory simulation of automobiles, can solve the problems of danger, affecting the electrophoresis effect, affecting the effect of phosphating electrophoresis, etc., and achieves the effect of cost saving and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

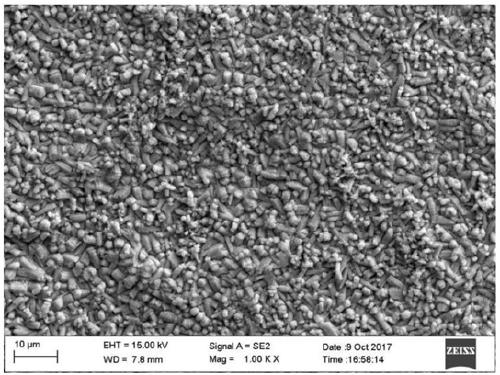

[0039] The 1.5mm thick DC03 steel newly taken by our company from the same coil is divided into two batches, one is hanged with the production line, and the other is phosphating test in the laboratory phosphating line.

[0040] The laboratory simulates the specific process and sample information of the phosphating method of the quenched steel plate production line for automobiles as follows: including pre-ironing, local ironing, pre-degreasing, local degreasing, tap water washing 1, tap water washing 2, surface conditioning, phosphating, Tap water washing 3, tap water washing 4, pure water washing 1, pure water washing 2 and air-drying process, the specific process steps are as follows:

[0041] (1) Pre-ironing process: Spray tap water with a watering can, the water temperature is 35°C, and the spraying time is 1min;

[0042] (2) The ironing process: heating with tap water constant temperature water bath, the temperature is 35°C, and the soaking time is 1.5min;

[0043] (3) P...

Embodiment 2

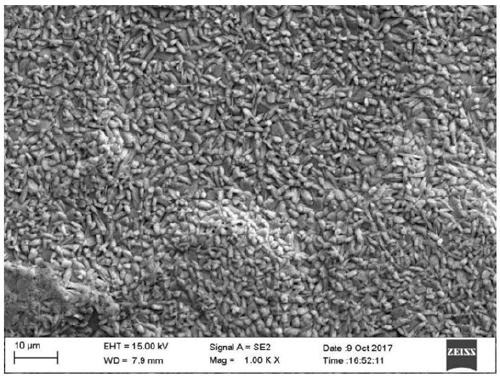

[0060] The 1.5mm thick DC01 steel newly taken by our company from the same coil is divided into two batches, one batch is phosphating with the production line, and the other is phosphating test in the laboratory phosphating line.

[0061] The laboratory simulates the specific process and sample information of the phosphating method of the quenched steel plate production line for automobiles as follows: including pre-ironing, local ironing, pre-degreasing, local degreasing, tap water washing 1, tap water washing 2, surface conditioning, phosphating, Tap water washing 3, tap water washing 4, pure water washing 1, pure water washing 2 and air-drying process, the specific process steps are as follows:

[0062] (1) Pre-ironing process: Spray tap water with a watering can, the water temperature is 50°C, and the spraying time is 2 minutes;

[0063] (2) This ironing process: use tap water to heat in a constant temperature water bath, the temperature is 50°C, and the soaking time is 2....

Embodiment 3

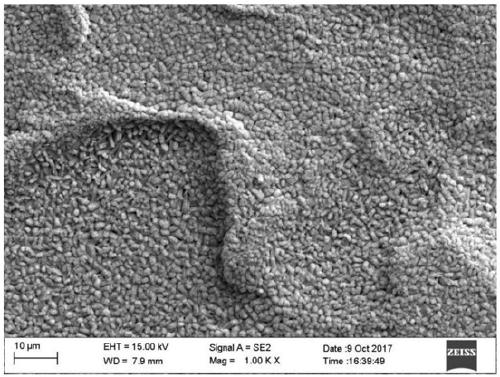

[0081] The 2.5mm thick DC01 steel newly taken from the same roll by our company is divided into two batches, one batch is phosphating with the production line, and the other is phosphating test in the laboratory phosphating line.

[0082] Laboratory phosphating line methods include pre-ironing, local ironing, pre-degreasing, local degreasing, tap water washing 1, tap water washing 2, surface conditioning, phosphating, tap water washing 3, tap water washing 4, pure water washing 1, pure water washing 2 And air-drying operation, concrete process steps are as follows:

[0083] (1) Pre-ironing process: Spray tap water with a watering can, the water temperature is 40°C, and the spraying time is 1.5 minutes;

[0084] (2) This ironing process: use tap water constant temperature water bath to heat, the temperature is 40 ℃, and the soaking time is 2.0min;

[0085] (3) Pre-degreasing process: Spray the sample with a watering can at a temperature of 40°C for 2.0 minutes;

[0086] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com